Transmission device of optical detector

A technology of optical detector and transmission device, which is applied in the direction of optical testing for flaws/defects, etc., which can solve problems such as error-prone, labor-intensive and time-consuming, and low efficiency, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

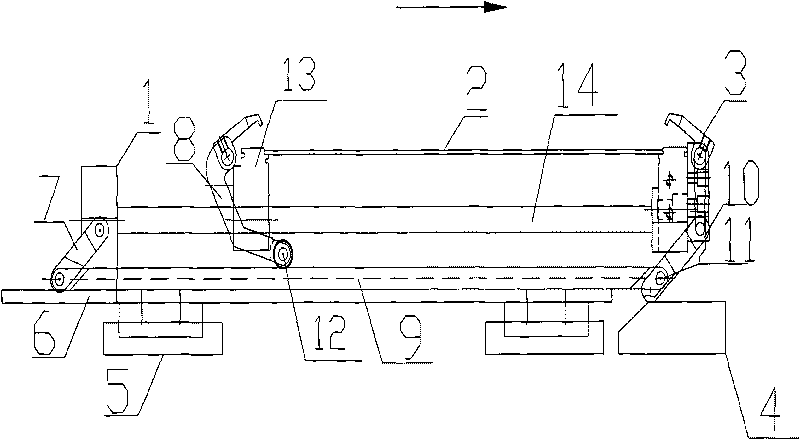

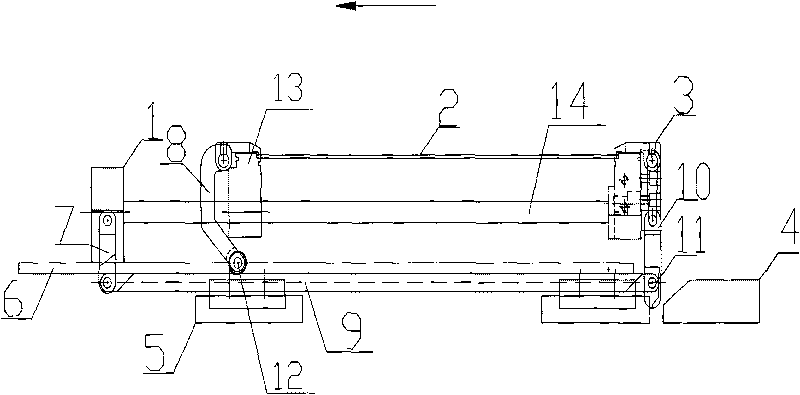

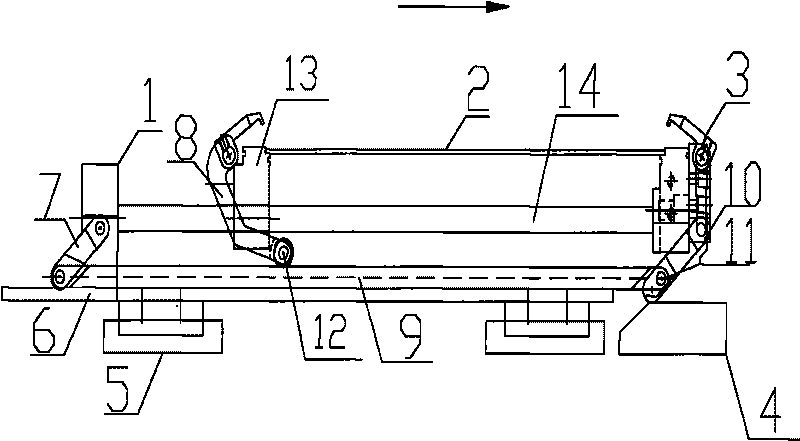

[0012] Such as figure 1 It is a schematic diagram of the movement of the transmission device of the optical detector of the present invention.

[0013] There are two slide rails (6) parallel to each other and perpendicular to the base (5) on the base (5), there is a blocking seat (4) at the end of the slide rail (6), and there is a connecting rod (14) on the slide rail (6). ) connected to the fixture tailstock (1) and the fixture table (13), the two ends of the fixture table (13) have symmetrically arranged pressure claws (3) and the steps for placing the PCB board (2), and the fixture tailstock (1) Connecting rod one (7) is connected through a rolling bearing, the end of the fixture table (13) away from the fixture tailstock (1) is connected with connecting rod four (10) through a rolling bearing, and connecting rod three (9) is connected to the connecting rod thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com