Method for adjusting motor current ring parameter

A motor current and parameter setting technology, which is applied in the direction of excitation or armature current control, can solve the problems of potentiometer aging, time-consuming and labor-intensive, and difficult for general users to grasp.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

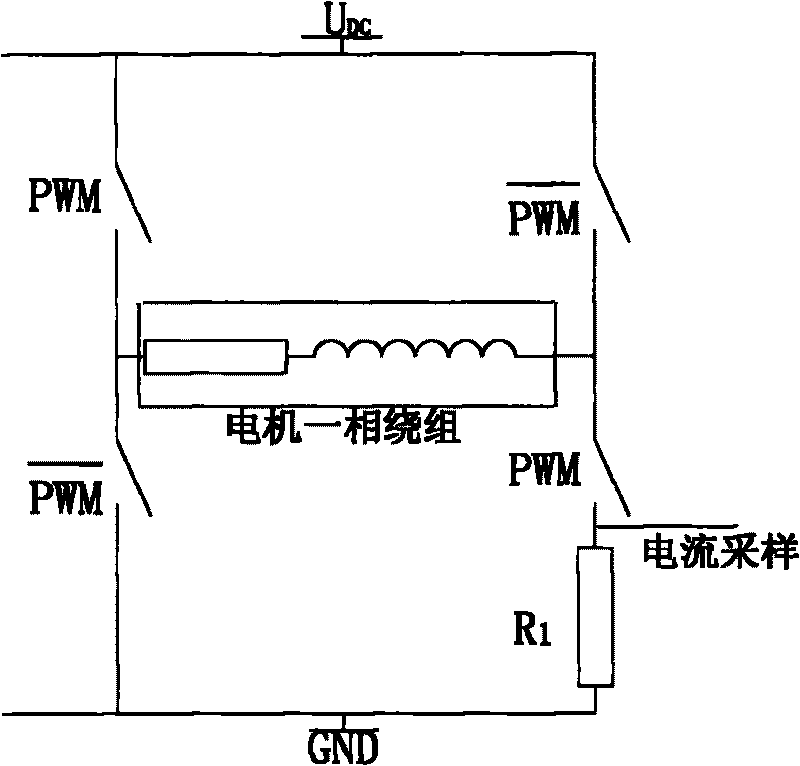

[0034] The scheme of this embodiment mainly includes the following steps:

[0035] i. Find the initial value of the PI parameter;

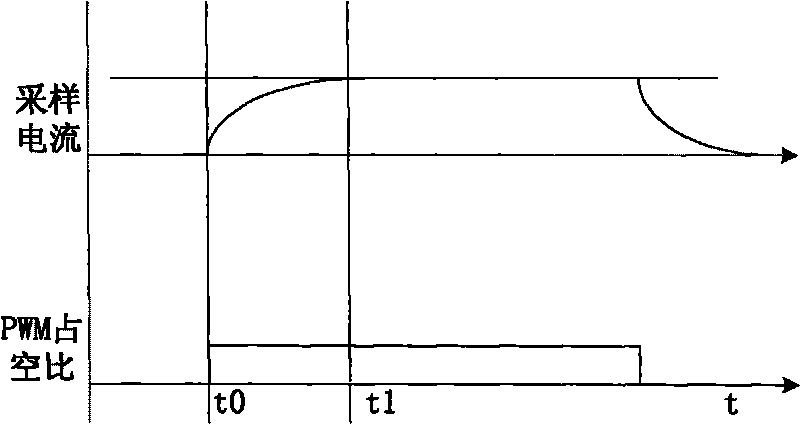

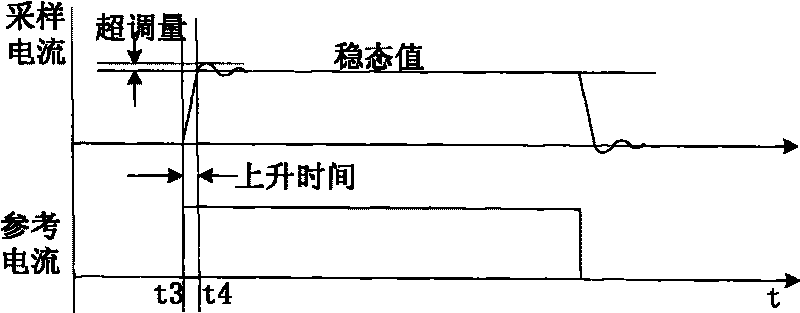

[0036] ii. Given the target current Iref, sample the actual current;

[0037] iii. Data processing and index extraction: extract three indexes of current rise time, overshoot and steady-state current value;

[0038] iv. According to the index, adjust the current loop parameters according to the change rule;

[0039] v. Repeat the above three processes (ii-iv) until the index meets the predetermined target.

[0040] The specific implementation is as follows:

[0041] First, according to the bus voltage, calculate the duty ratio d% of a fixed voltage (usually 3-5V) according to formula 1:

[0042] d = u U DC * T (Formula 1)

[0043] in

[0044] d: output PWM duty cycle

[0045] u: given voltage, generally fixed at 3~5V

[0046] u DC : DC bus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com