Improved type PE pipe texturing machine

An improved, deforming machine technology, applied in the direction of tubular objects, applications, household appliances, etc., can solve the problems of not suitable for PE pipe deformation construction needs, accident fixed anchors, PE pipe damage and other problems, to improve work efficiency, operation Convenience and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

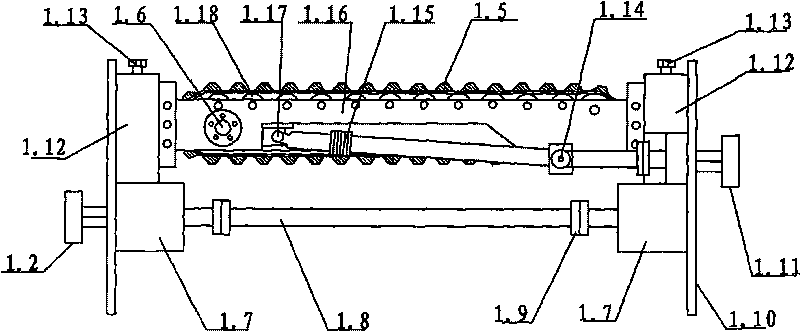

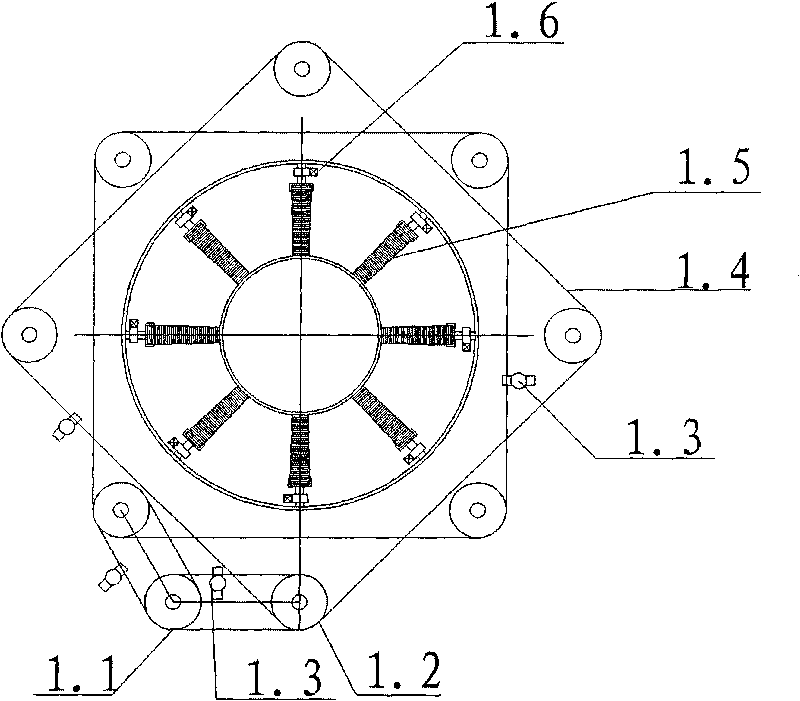

[0039] This embodiment consists of three parts, which are respectively a PE pipe conveying mechanism, a PE pipe extruding mechanism and a PE pipe forming mechanism.

[0040] The PE pipe conveying mechanism, the PE pipe extruding mechanism and the PE pipe forming mechanism are sequentially connected and assembled on the frame 1.10. The PE pipe conveying mechanism transports the PE pipe into the PE pipe extruding mechanism. After the PE pipe is extruded by the PE pipe extruding mechanism, its The cross-section is elliptical, and then the PE pipe forming mechanism presses the PE pipe into shape, and finally into the maintenance pipeline.

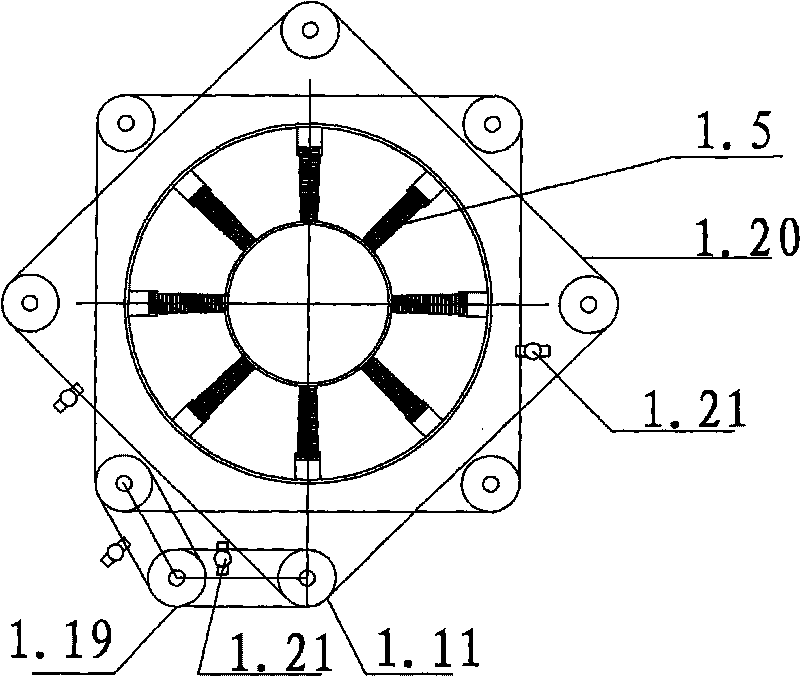

[0041]The PE pipe transmission mechanism is composed of eight transmission mechanisms that are evenly distributed around the circumference and fixed on the frame 1.10. The motor drives the drive electric wheel 1.19 to rotate. Drive electric wheel 1.19 drives adjacent two drive sprockets 1.11 to rotate by two transmission chains 1.20, drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com