Anti-side rolling torsion rod axis for railway vehicle and manufacturing method thereof

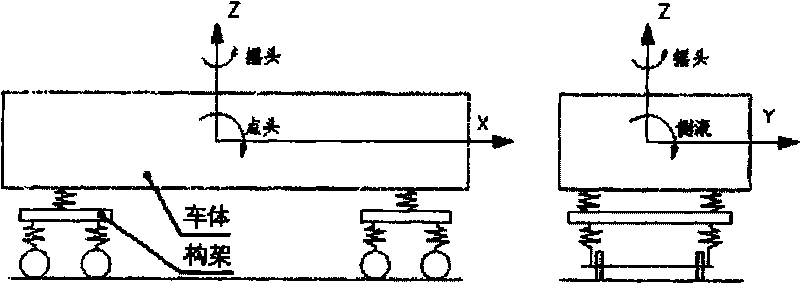

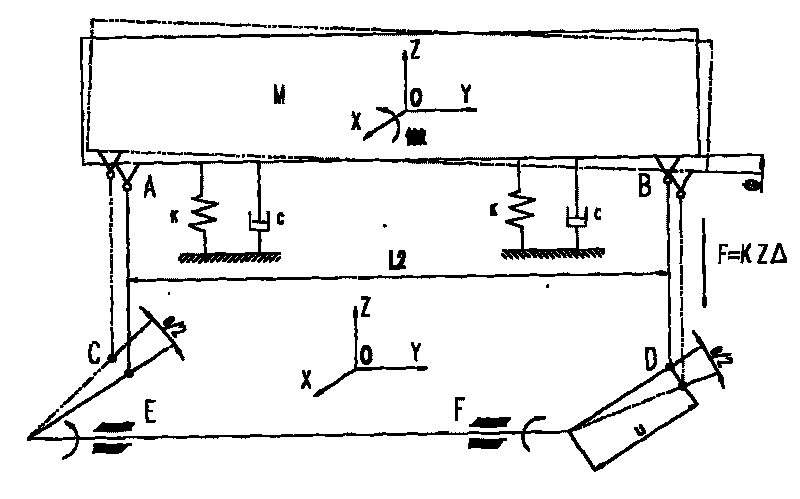

A technology of anti-rolling torsion bars and rail vehicles, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, and can solve the problem of small vertical stiffness of the air spring, reduced vehicle safety and smooth running performance, and can not affect the vehicle Vibration characteristics and other issues, to achieve the effect of good mechanical processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

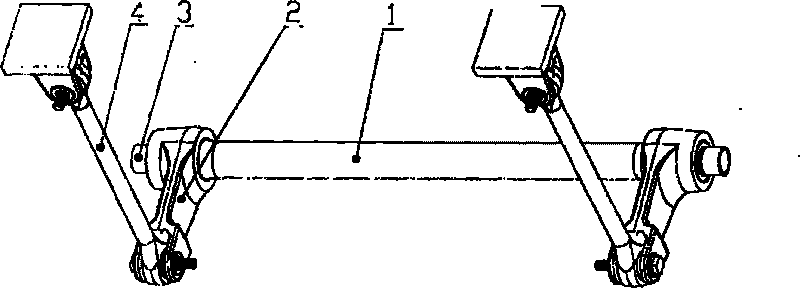

[0024] attached Figure 6 An embodiment of the present invention is given, and the present invention will be further described below in conjunction with the accompanying drawings.

[0025] As can be seen from the accompanying drawings, the present invention is a novel rail vehicle torsion bar shaft, comprising a torsion bar shaft 1, the torsion bar shaft 1 is connected with the vertical connecting rod 4 through the torsion arm 2, and the torsion bar shaft The two ends of the shaft 1 are provided with supporting seats to form 3; the two ends of the torsion bar shaft 1 are stepped shafts; the characteristic is that the transition of the stepped positions at the two ends of the torsion bar shaft is a concave curved surface structure transition. The concave curved surface structure transition means that the concave curved surface is the transition from the stepped small axis to the stepped large axis, starting at about 5-10 mm from the end of the stepped small axis to below The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com