Saccharifying wort cooker and beer saccharifying device using same

A technology of boiling pot and chemical device, applied in the field of beer brewing, can solve the problems of difficulty in producing high-quality wort, inability to use heating device, limited use of equipment, etc., and achieves the improvement of wort quality, increased strength and material saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

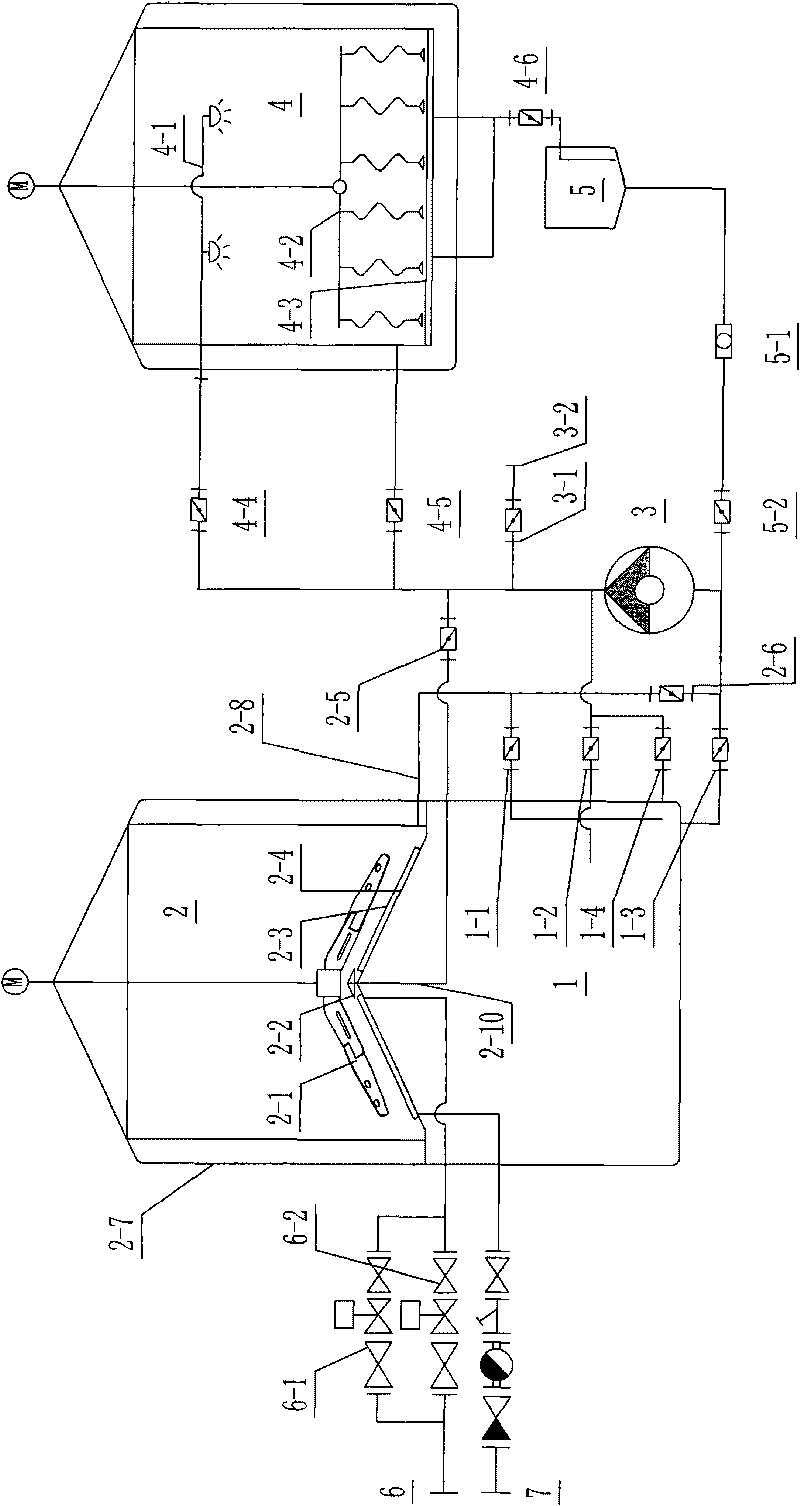

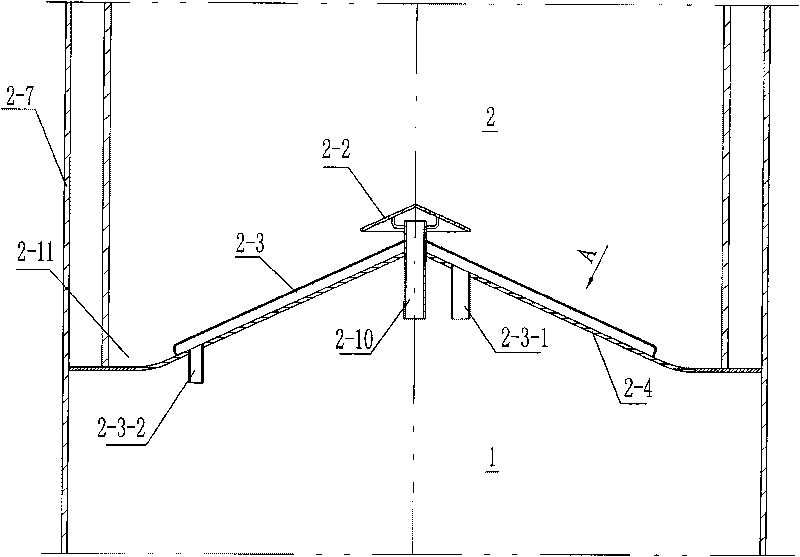

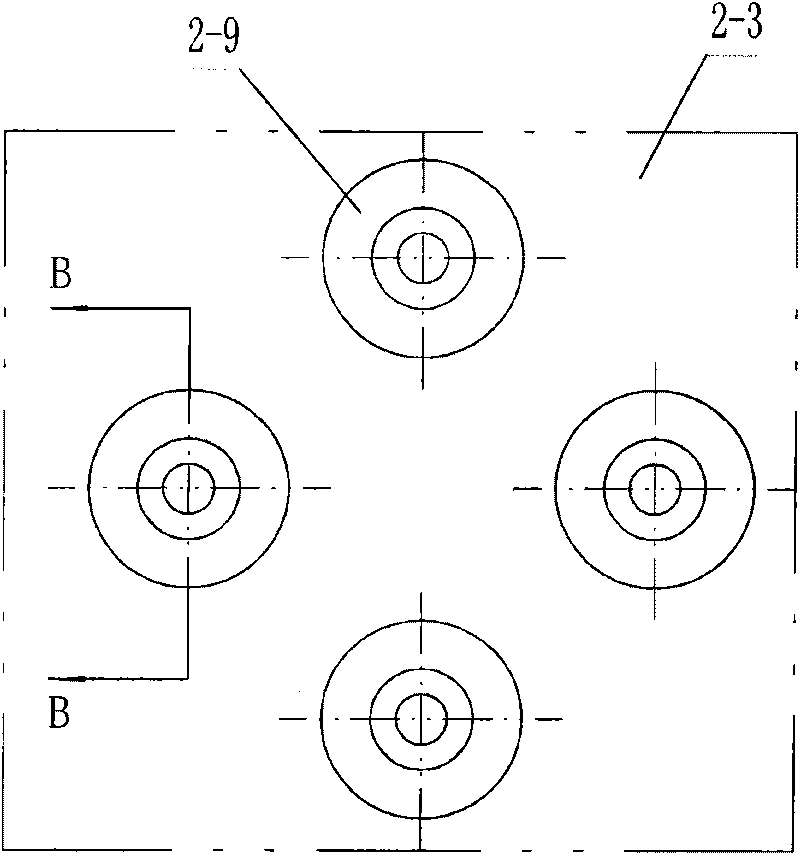

[0028] Such as Figure 1 ~ Figure 4 As shown, the saccharification boiling pot in this embodiment has a pot body 2-7, a wort outlet 2-8 is provided on the pot body 2-7, and a stirring device 2-8 is arranged in the pot body 2-7. 1. The bottom of the pot body is a convex bottom 2-4 protruding upwards. The convex bottom 2-4 is provided with a steam heating jacket 2-3, and the jacket 2-3 is connected with a steam inlet 2-3-1 and The steam outlet 2-3-2, the upper surface of the jacket 2-3 is densely covered with small pits 2-9 in a honeycomb shape, and a wort inlet pipe 2-10 passes through the middle of the convex bottom 2-4 and opens at Inside the pot body 2-7, with the opening facing upwards, there is a wort distribution plate 2-2 upside down above the opening, the lower surface of the wort distribution plate 2-2 is in an upward concave shape, and the wort distribution plate 2-2 Leave the gap that allows wort to flow out between the opening of wort inlet pipe 2-10. A swirl sett...

specific Embodiment approach

[0039] First, add a certain amount of brewing water into the mashing kettle 2, start the stirring 2-1, and pour in malt while stirring. After the mixing of malt and water is completed, the steam inlet valve group 6-1 is opened for heating and saccharification. After the saccharification is completed, close the valve group 6-1 and the stirring 2-1, open the wort outlet valve 2-6, the malt mash inlet valve 4-5, turn on the sanitary centrifugal pump 3, and pump the saccharified malt mash into the lauter tank 4.

[0040] After the malt mash is pumped out, a certain amount of brewing water is added to the saccharification kettle 2, the steam inlet valve group 6-2 is opened, heated to a certain temperature, and the hot water is used for washing the grains.

[0041] 2. The specific implementation of filter tank 4:

[0042] When the malt mash is pumped in from the malt mash inlet valve 4-5, the tillage device 4-2 is opened. After the malt mash has been pumped, close the malt mash i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com