Method for prolonging service life of vacuum pump of single crystal furnace

A technology of vacuum pump and single crystal furnace, applied in single crystal growth, chemical instruments and methods, crystal growth and other directions, can solve the problems such as the decrease of the pumping speed of the vacuum pump, and achieve the effect of improving the service life and saving the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

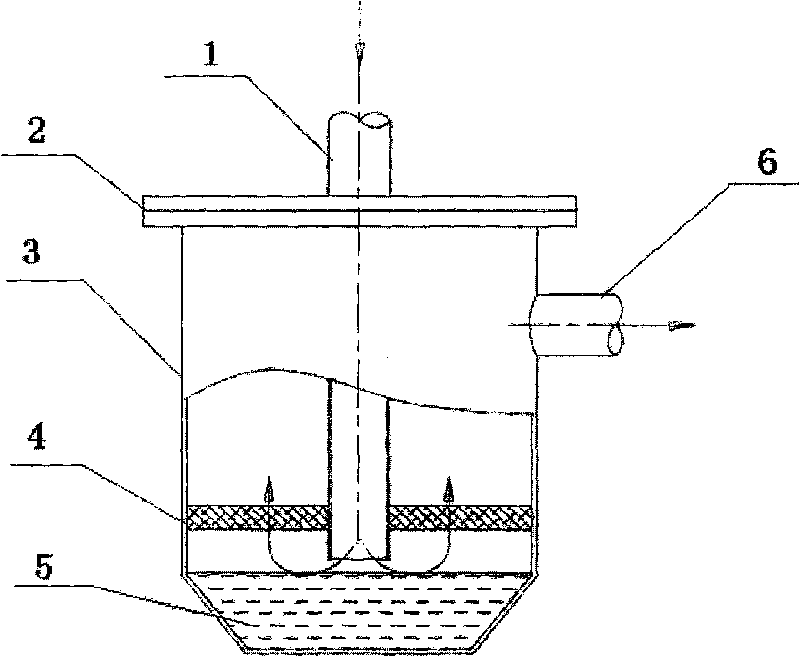

[0014] refer to figure 1 , the oil filter of the present invention is installed between the vacuum pump and the furnace body, and includes a filter cavity 3, a filter cover 2 located at the top of the cavity, and an air intake pipe 1 located in the center of the filter for connecting The outlet pipe of the furnace chamber; an exhaust pipe 6 located on the side of the filter cavity is connected to the vacuum pump. The filter cavity 3 has a silicone oil layer 5 at the bottom, which is composed of vacuum pump oil and is used to adsorb fine impurities in the gas; there is a stainless steel filter screen 4 above the silicone oil layer 5, which is used to filter relatively small impurities. Coarse particle impurities, the outlet of the intake pipe 1 is located between the silicone oil layer 5 and the filter screen 4 . The arrows in the figure indicate the gas flow direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com