Slotted cylinder variable frication damper

A technology of variable friction and damper, applied in the direction of friction shock absorber, etc., can solve the problems such as the inability to accurately predict the strength, the working state that deviates from the expected design, and the inability to take into account strong and weak vibrations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described below in conjunction with embodiment.

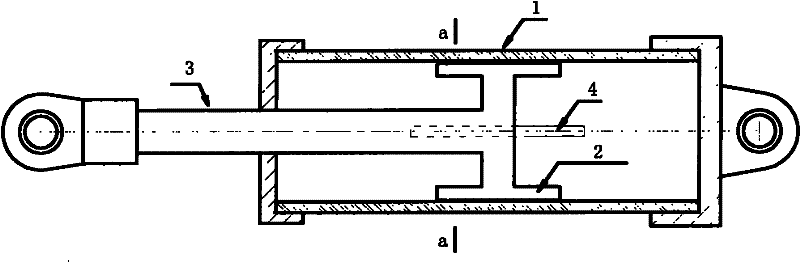

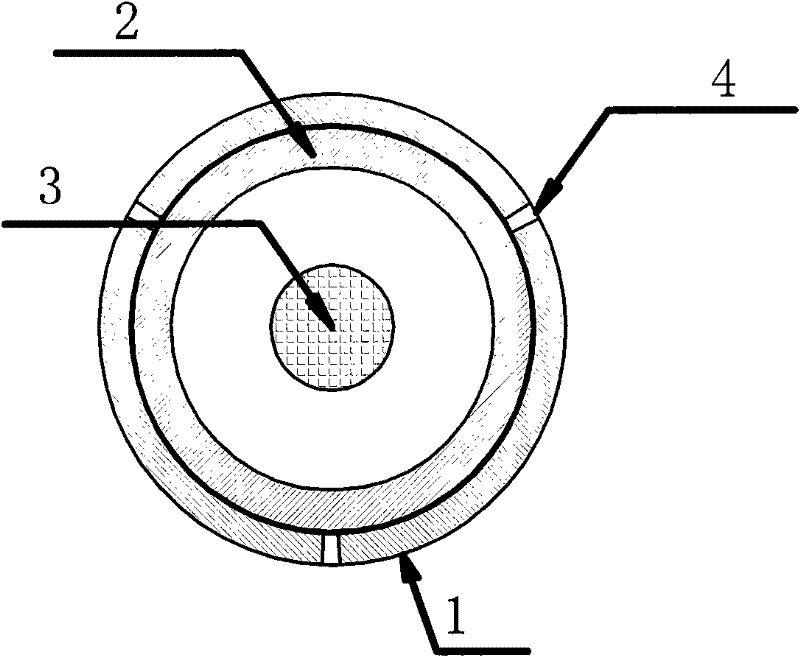

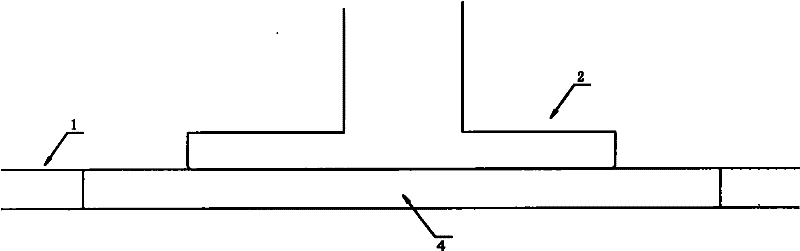

[0018] like Figure 1-3 As shown, a slotted cylindrical variable friction damper includes a cylinder 1, a friction ring 2, and a sliding shaft 3, and the cylinder 1 has a vertical slit 4 in the middle; the friction ring 2 is installed on the cylinder 1. The position of the vertical seam 4 is aligned with the center of the vertical seam 4; the size of the vertical seam 4 along the length direction of the cylinder is larger than the axial length of the friction ring 2; the outer diameter of the friction ring 2 is slightly larger than the inner diameter of the cylinder 1; the friction ring 2 It is compressible, and the cylinder 1 is expandable; the axes of the friction ring 2 and the sliding shaft 3 are overlapped and connected as a whole;

[0019] The slotted cylindrical variable friction damper in this embodiment can provide a hysteretic curve of variable friction damping force, Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com