Electrophoretic display panel

An electrophoretic display and panel technology, used in nonlinear optics, instruments, optics, etc., can solve the problems of poor display quality of electrophoretic displays and affect the characteristics of components, and achieve the effect of good display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

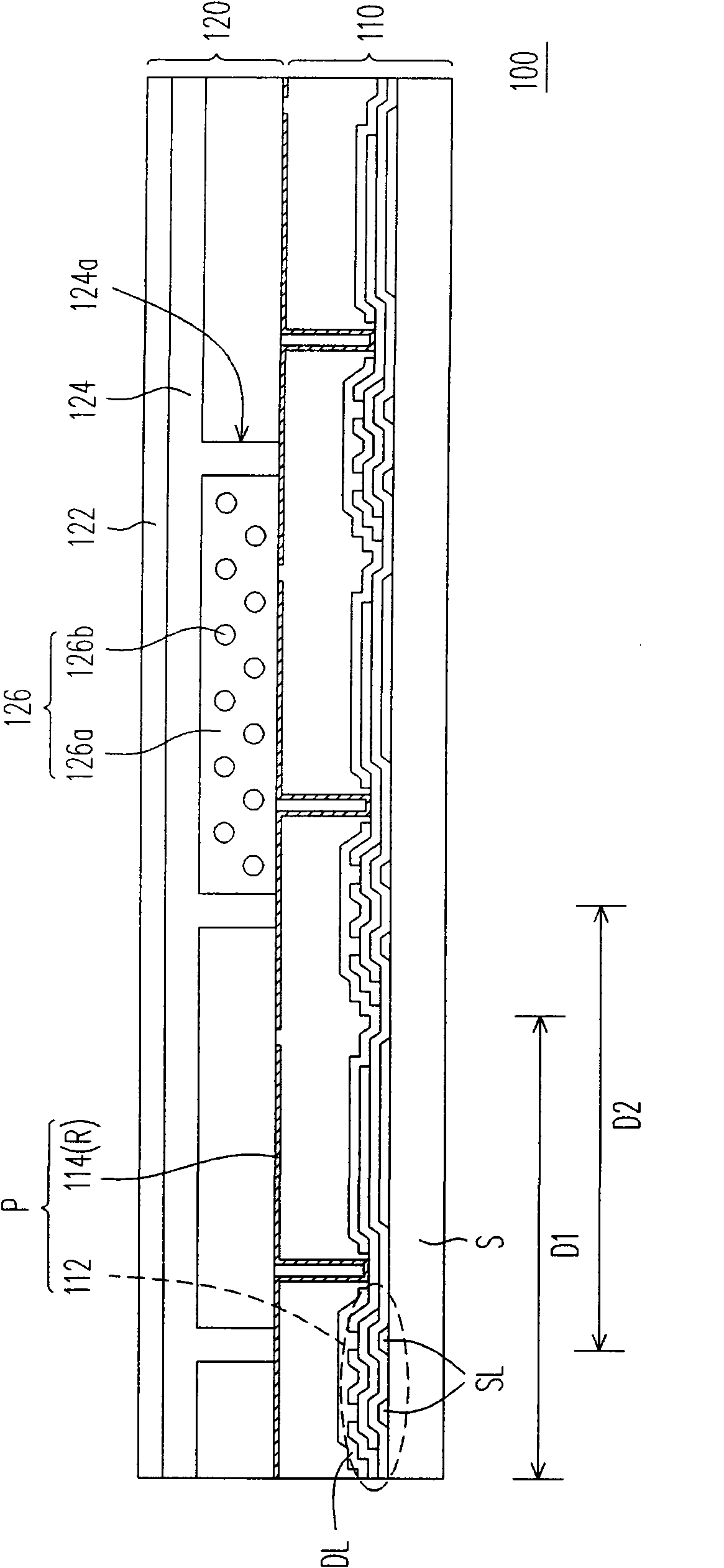

[0030] figure 1 It is a schematic cross-sectional view of the electrophoretic display panel according to the first embodiment of the present invention. Please refer to figure 1 The electrophoretic display panel 100 of this embodiment includes an active device array substrate 110 and an electrophoretic display film 120 . The active device array substrate 110 includes a plurality of active devices 112 and a light shielding layer 114 covering the active devices 112 . The electrophoretic display film 120 is disposed on the active device array substrate 110 , and the electrophoretic display film 120 includes a conductive layer 122 , a dielectric layer 124 and a plurality of electrophoretic display media 126 . Such as figure 1 As shown, the dielectric layer 124 is disposed on the lower surface of the conductive layer 122, the dielectric layer 124 has a plurality of microcups 124a arranged in an array and located on its lower surface, and the dielectric layer 124 is located betwee...

no. 2 example

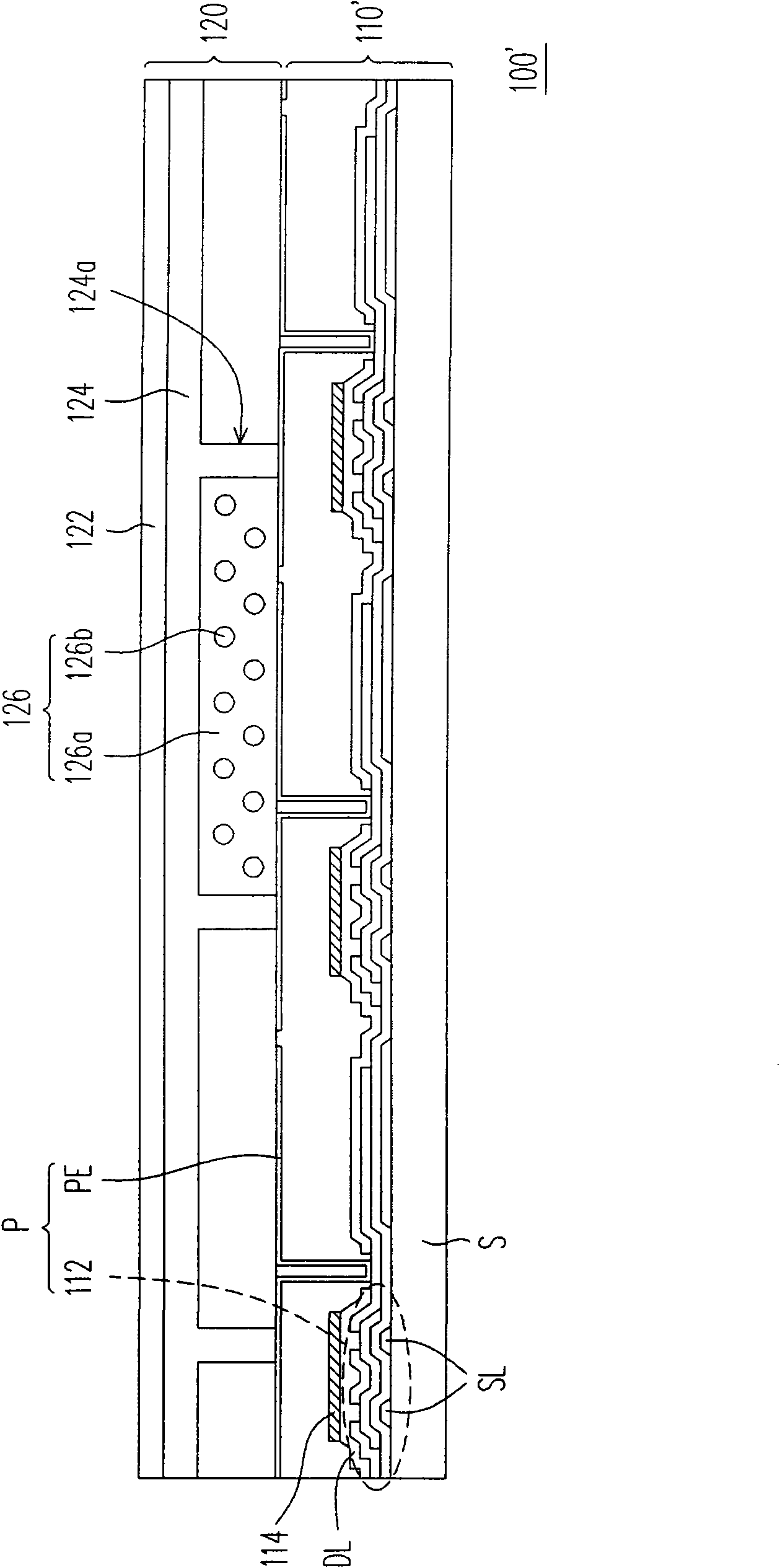

[0036] figure 2It is a schematic cross-sectional view of the electrophoretic display panel according to the second embodiment of the present invention. Please refer to figure 2 , the electrophoretic display panel 100' in this embodiment is similar to the electrophoretic display panel 100 in the first embodiment, but the main difference between them is that the light shielding layer 114 in the active element array substrate 110' in this embodiment is located Between the pixel electrode PE and the active device 112 , and the active device 112 and the pixel electrode PE form a plurality of pixels P. In other words, the light-shielding layer 114 and the pixel electrode PE belong to different film layers, which are different from the reflective pixel electrode R of the first embodiment.

[0037] Based on the above, the light-shielding layer 114 of this embodiment can be a metal layer with a single-layer structure, a metal layer with a multi-layer structure, a light-shielding la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com