Reactor unit

A technology for reactors and electrical terminals, applied in the direction of inductors, electrical components, fixed inductors, etc., can solve problems such as difficult operation, high soldering cost, and poor contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. At the same time, it should be pointed out that the embodiments of the present invention do not limit the scope of the present invention.

[0020] (Example)

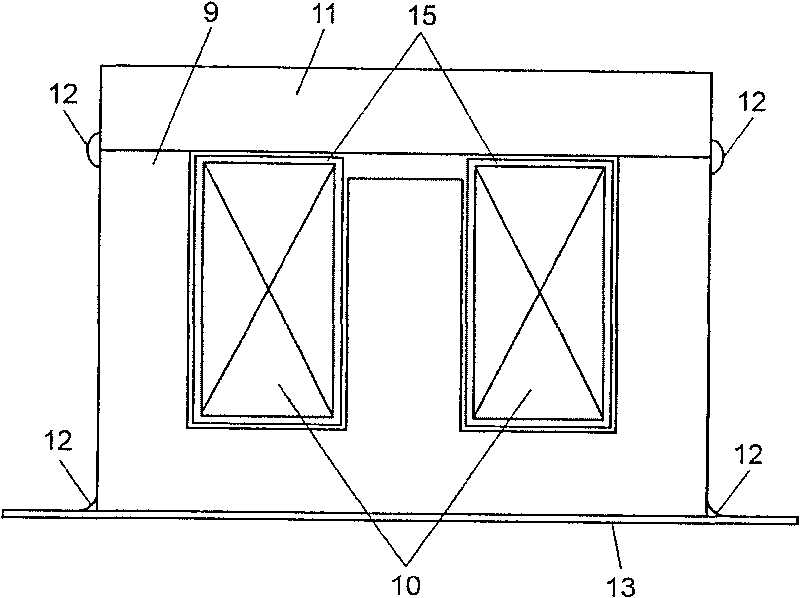

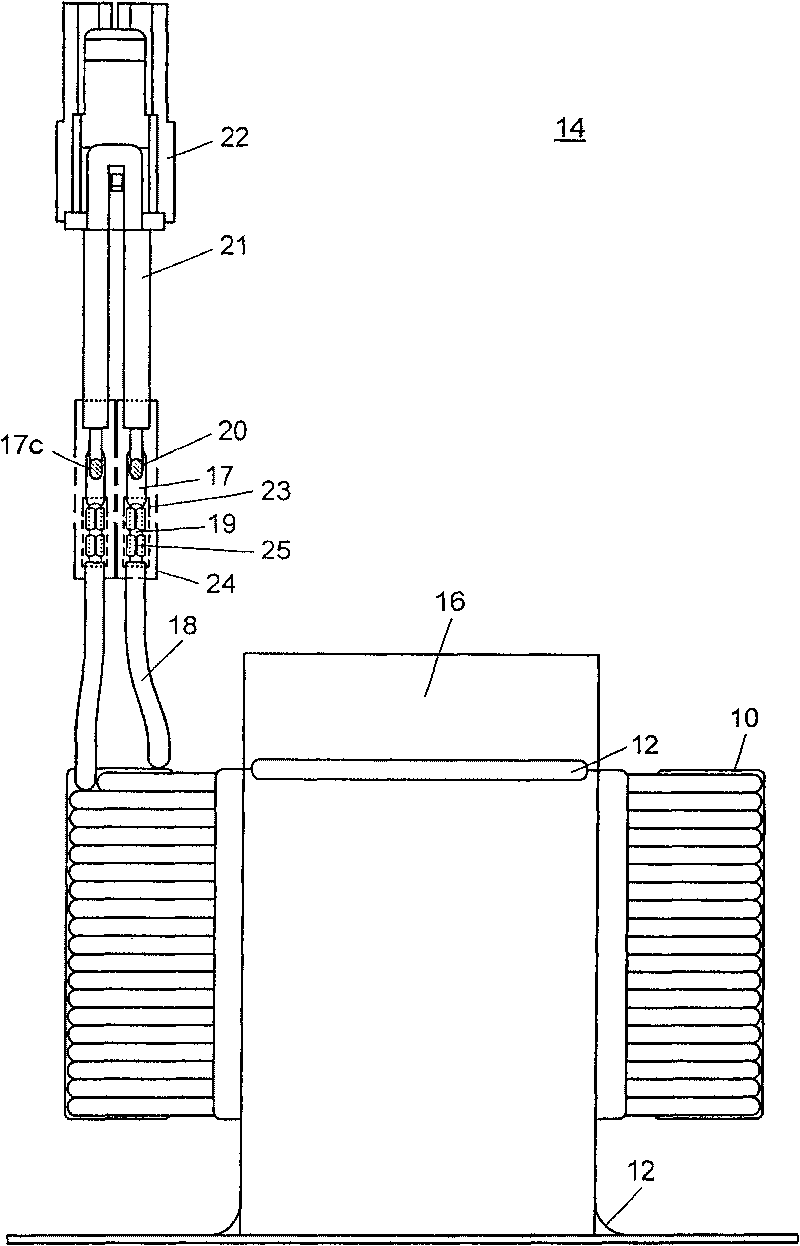

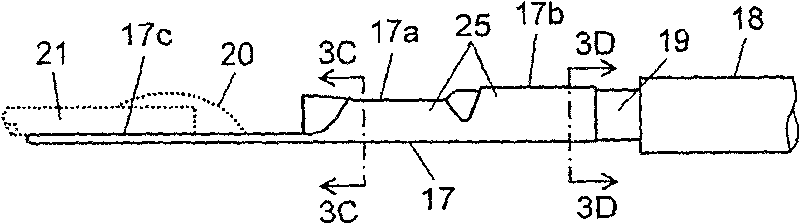

[0021] Refer below Figure 1 ~ Figure 4 The reactor unit of this embodiment will be described. The reactor unit of this embodiment is used to suppress the high-frequency current in the washing machine and the like for frequency conversion control, and improve the power factor. The winding coil uses aluminum wire, and the power input part uses copper wire. Between the winding coil and the copper wire Equipped with electrical connections.

[0022] figure 1 is a sectional view of the reactor unit in this embodiment. Such as figure 1 As shown, the electromagnetic thin steel plate is punched into the shape of the English letter "E" by a stamping die, and then laminated / welded to form an E-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com