Preparing method of magnetic ring for reactor

A reactor and magnetic ring technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve the problems of affecting the shape of the reactor and increasing the loss of the reactor, and achieve improved performance, low magnetic permeability, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Mix ferrite powder with a particle size of 20 μm and epoxy resin glue (specifically selected from Tianjin Jitai Yifeng Company, model TJH-5217A) to form a mixture in a weight ratio of 4:1;

[0019] b. Put the mixture into the blender and stir for 32 minutes to stir evenly;

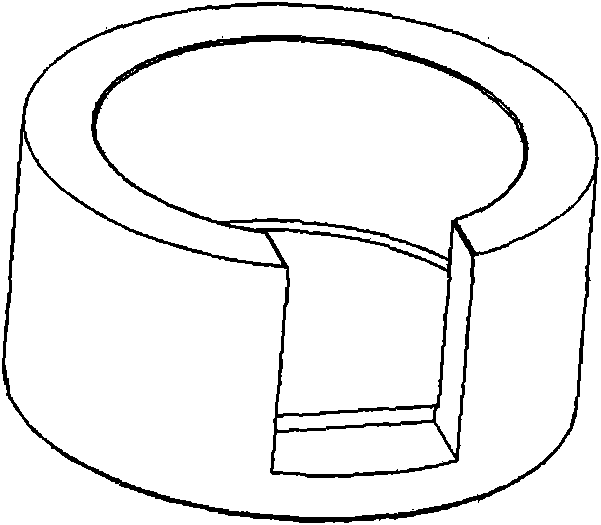

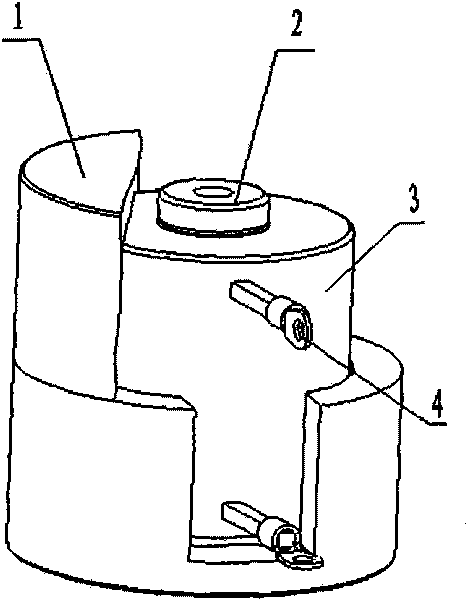

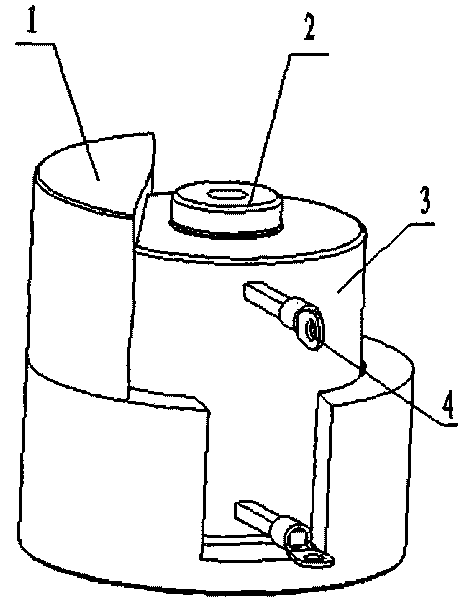

[0020] c. Put the well-stirred mixture into a forming mold, and press it on a press;

[0021] d. Put the formed magnetic ring (1) together with the forming mold into an oven, and dry it continuously at 125°C for 3.5 hours, and then control the temperature to drop evenly to room temperature within 1.2 hours;

[0022] e. Take out the magnetic ring (1) and demould it.

Embodiment 2

[0024] a. Mix sendust with a particle size of 30 μm and epoxy resin glue (specifically selected from Tianjin Jitai Yifeng Company, model TJH-5217A) in a weight ratio of 4:1 to form a mixture;

[0025] b. Put the mixture into the blender and stir for 30 minutes to stir evenly;

[0026] c. Put the well-stirred mixture into a forming mold, and press it on a press;

[0027] d. Put the formed magnetic ring (1) together with the forming mold into an oven, and dry it continuously at a temperature of 120°C for 3 hours, and then control the temperature to drop evenly to room temperature within 1.5 hours;

[0028] e. Take out the magnetic ring (1) and demould it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com