Turbine rotor and power plant

A technology for turbine rotors and power generation equipment, which is applied to mechanical equipment, wind power generation, hydropower generation, etc., and can solve problems such as large-diameter hubs with closed and hollow anti-torque sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

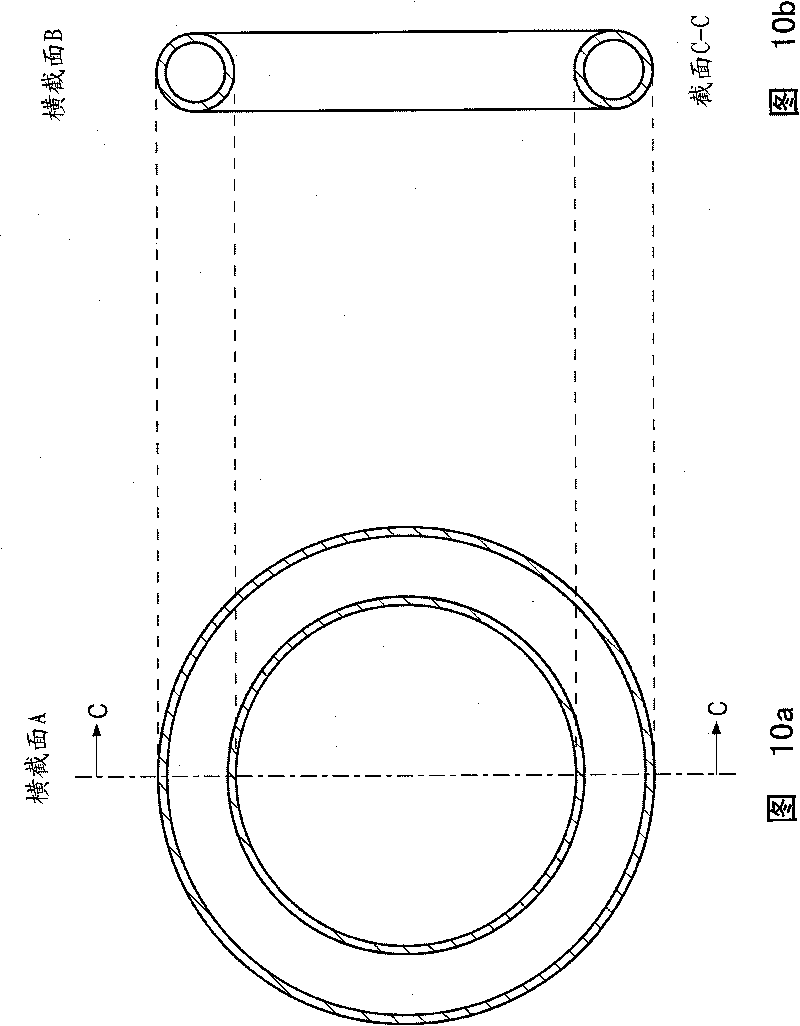

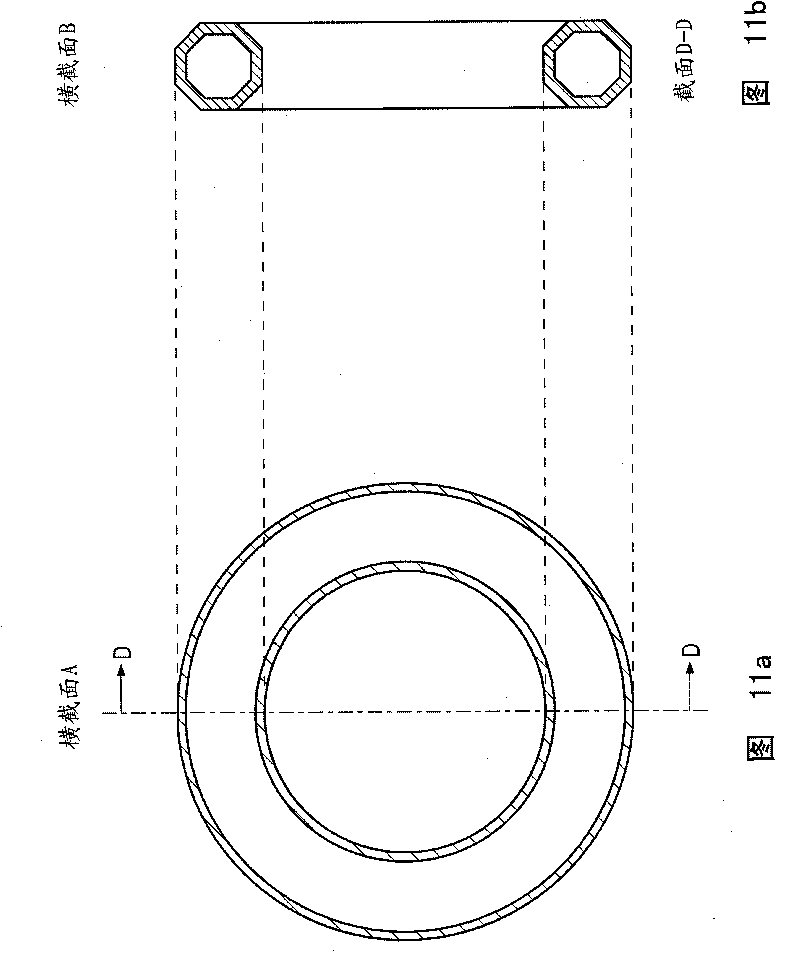

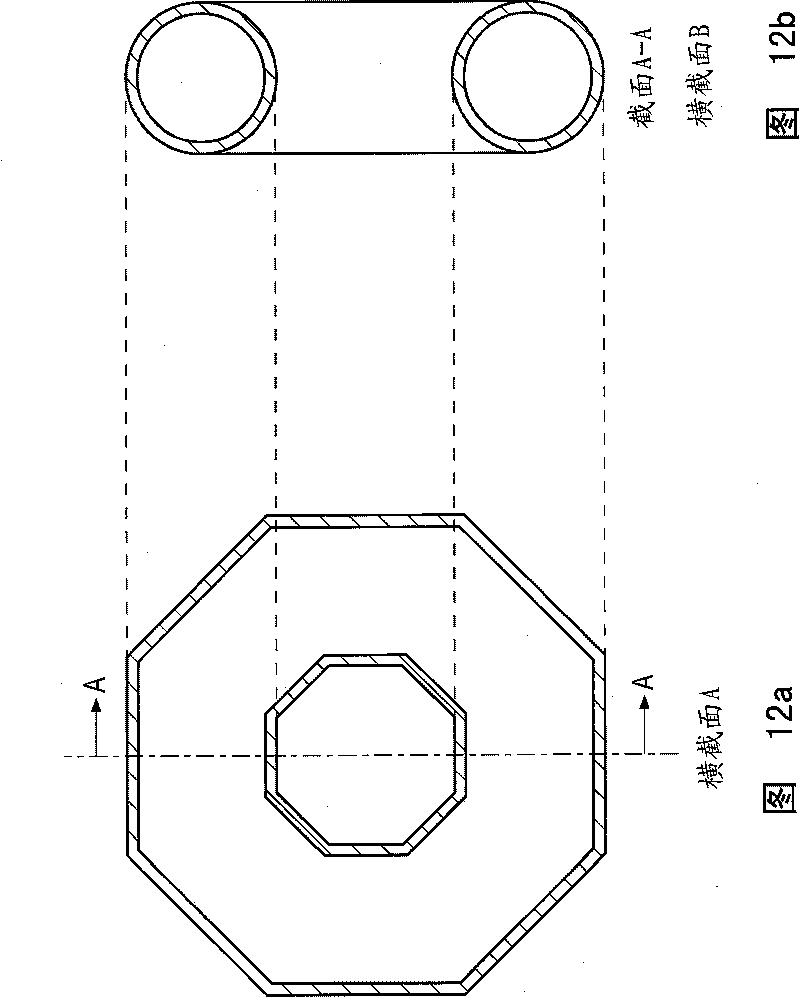

[0102] In the following, a first embodiment of the invention relates to an embodiment in which the donut-shaped hub is at least partly supported on the stator by means of a magnetic bearing, as shown for example in Figure 6 and 7 , a second embodiment of the invention relates to an embodiment in which a hub in the shape of a donut is supported on a central hub, such as Figure 8 shown.

[0103] figure 1 Shown is a wind power plant 1 with an output of 10-12 MW equipped with a large generally donut-shaped hub 6, 105, wherein the donut-shaped hub may have a diameter of about 20 metres. The donut-shaped hub 6, 105 may have a diameter in cross-section B of approximately 3 meters. The rotor blades 3, 4, 5 may each have a length of 60 m and are mounted on pitch bearings 8, 9, 10 as figure 2 As shown, the pitch bearing is arranged to enable rotation of the blade about its longitudinal axis in response to a push from a pitch control system (not shown). For example Figure 8 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com