Rotating device for eggs and conveying mechanism for eggs

A rotating device and poultry egg technology, which is applied in poultry farming, application, animal husbandry, etc., can solve the problems of limited poultry egg processing efficiency, and the processing capacity of poultry eggs is only 6,500, achieving the effect of increased speed and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

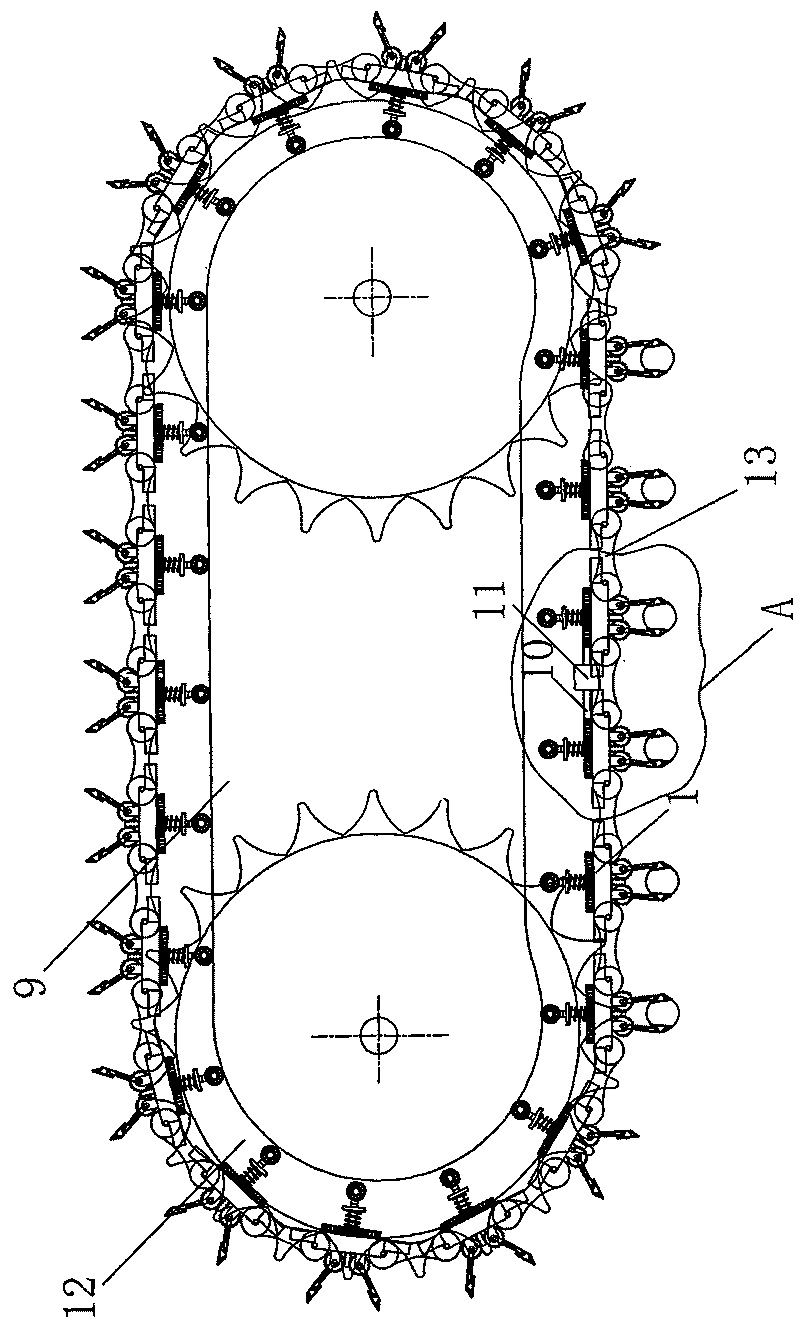

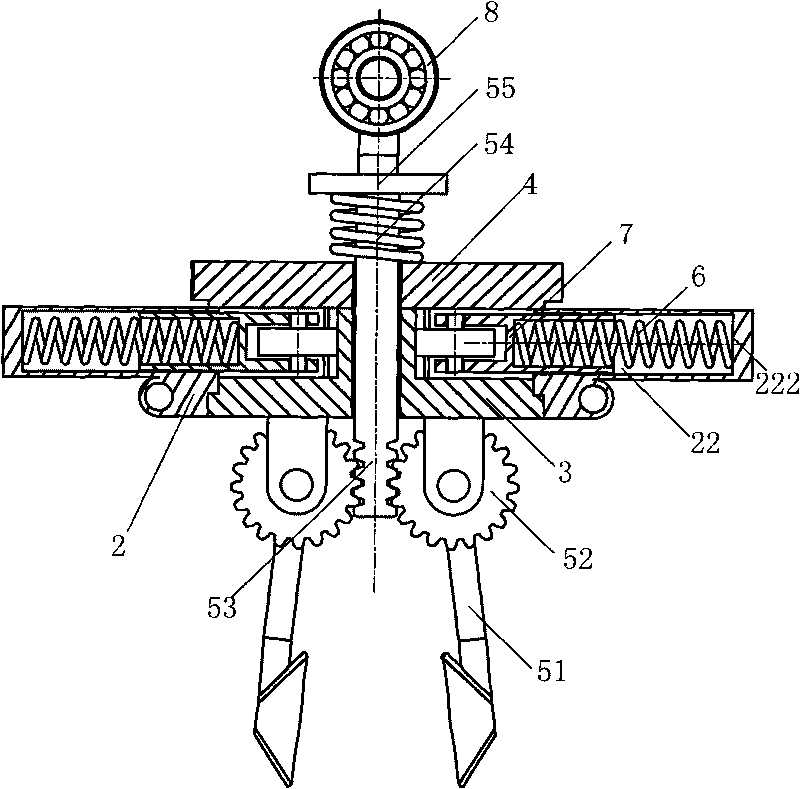

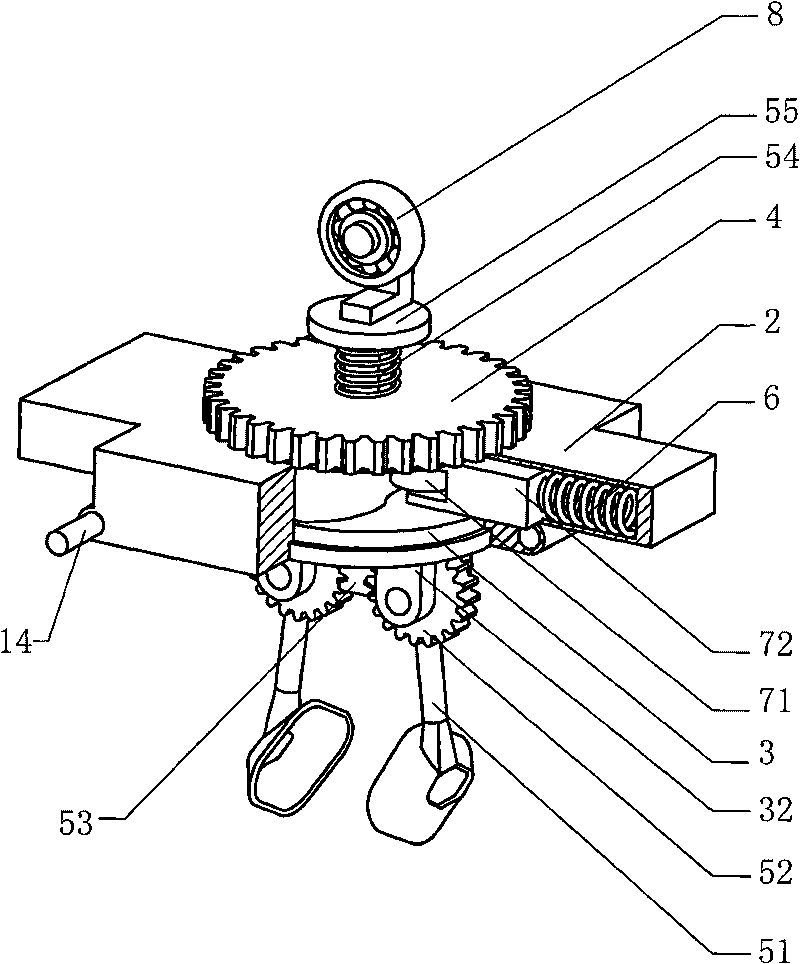

[0028] Such as Figure 1 to Figure 15 As shown, the poultry egg rotary conveying mechanism of the present invention includes a poultry egg rotating device 1 and a conveying device. The conveying device is mainly composed of two pairs of sprockets 12, two pairs of conveying chains 13, and a support plate 9. The side profile of the support plate 9 The opening or closing of the jaws 51 of the rotating device 1 is controlled, and in practical applications, the edge profile of the support plate 9 can be set according to the specific needs of the user. The rotating device 1 is connected with the conveying chain 13, adopts two sets of conveying chains 13 with the same specification and the spatial positions are parallel to each other, utilizes the four mounting rods 14 on the rotating device 1, and positions the mounting rods 14 two by two on each pair of conveying chains 13. The link joints on the chain 13, so that the rotating device 1 is installed on the conveyor chain 13, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com