Bar mill roller system sealing device

A sealing device and bar rolling mill technology, which is applied in the sealing of the engine, keeping the roll equipment in an effective state, metal rolling, etc., can solve the problems of high difficulty in end face seam processing, poor precision, and poor sealing of the sealing pair, etc. Achieve the effects of simple processing, enhanced water rejection ability, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

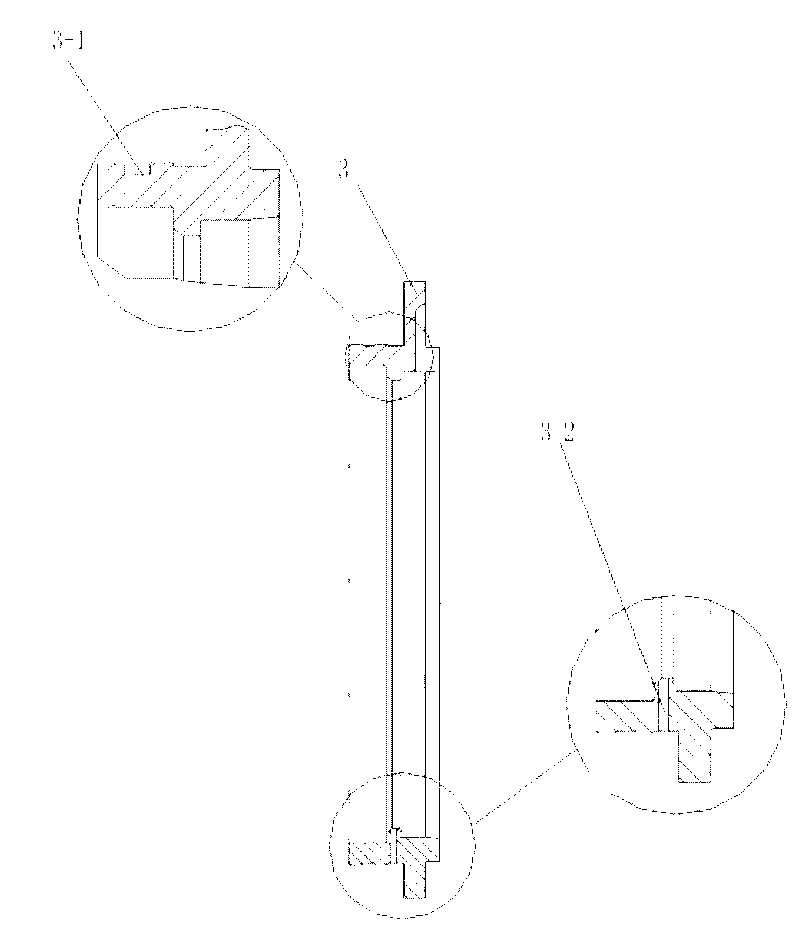

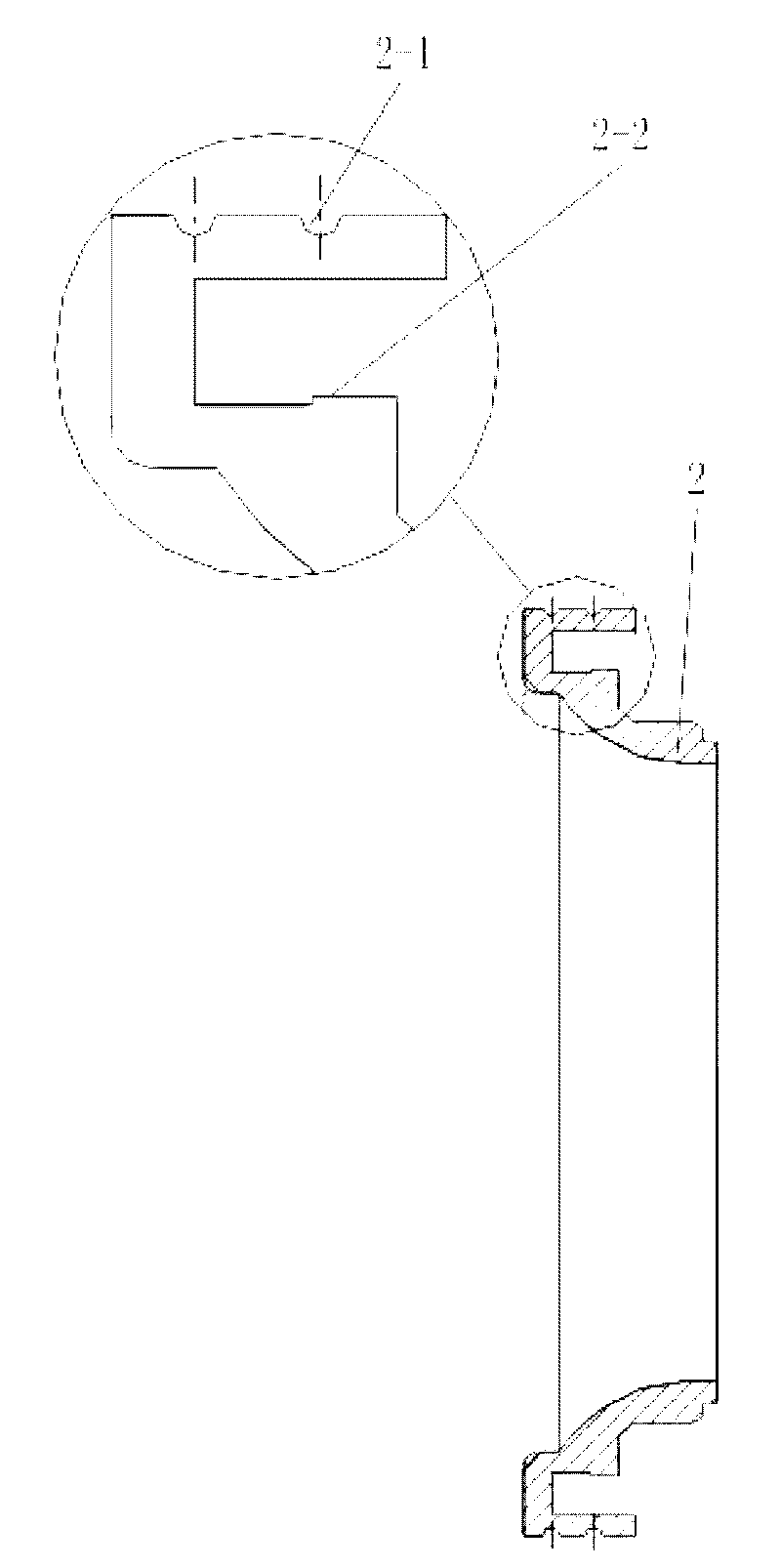

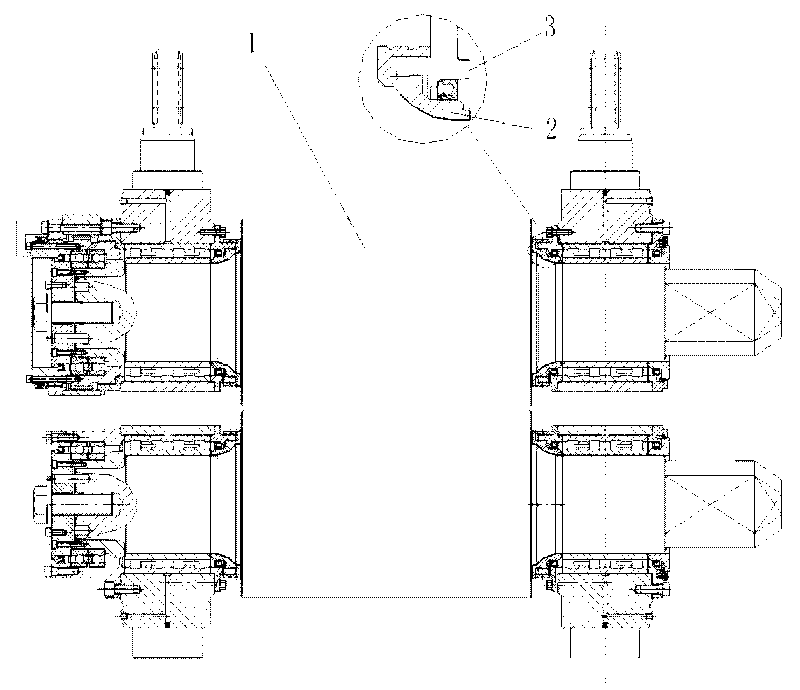

[0012] Below in conjunction with the preferred embodiments, the specific implementation methods provided according to the present invention are described in detail as follows: See the accompanying drawings for details, a roll system sealing device for a bar mill, including a sealing pair placed on the inner shoulder of the roll 1, the sealing The pair is composed of a labyrinth ring 2 with an annular slit and a labyrinth cover 3 inserted into the slit. An annular groove 3-1 is provided on the outer surface of the labyrinth cover and the labyrinth ring in the insertion direction. A small hole 3-2 is radially provided on the outer surface of the labyrinth cover and the labyrinth ring in the insertion direction, and the water entering the annular labyrinth seal ring groove can be discharged through the small hole. The notch on the end face of the labyrinth ring is composed of two circular grooves to form a stepped notch 2-2 whose diameter is larger inside and smaller on the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com