Noise-reduction damping device of train wheel

A technology for train wheels and damping devices, which is applied to wheels, wheels characterized by rail running parts, wheel cover plates, etc., can solve problems such as peeling off and limited noise reduction effects, and achieve vibration suppression, convenient implementation, and easy installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

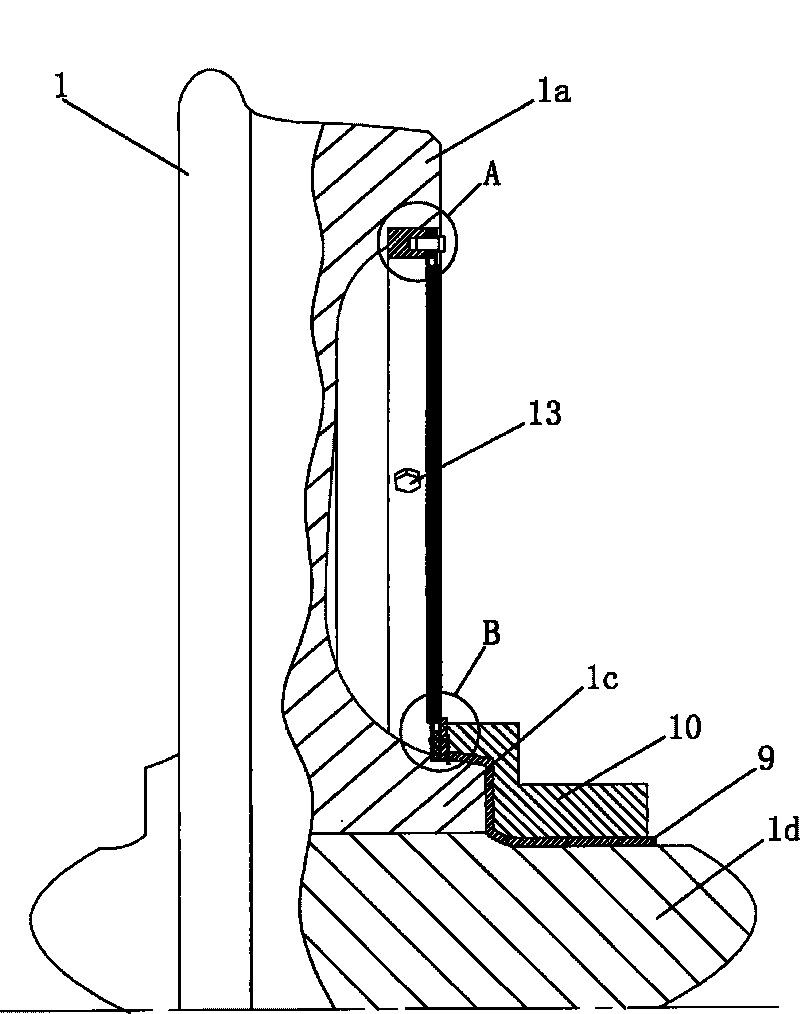

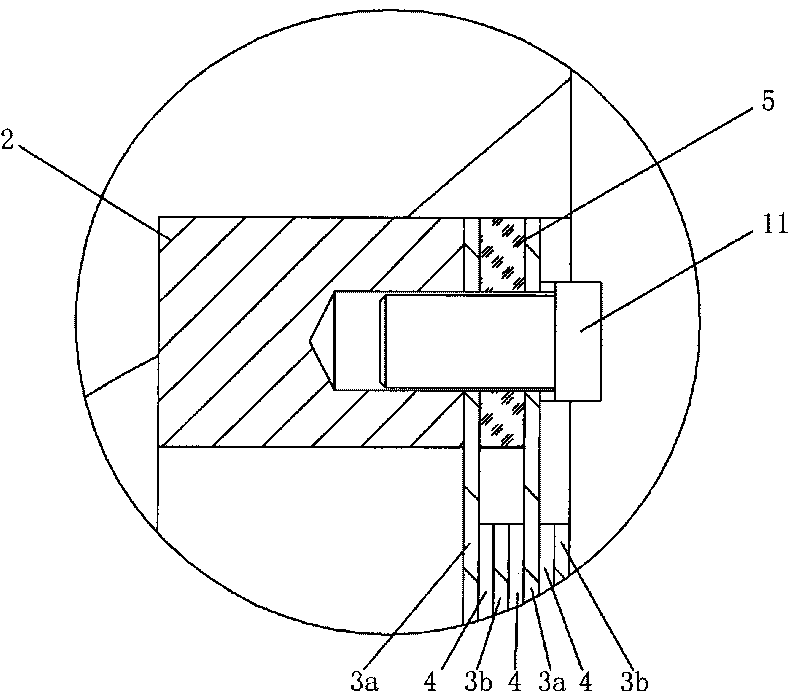

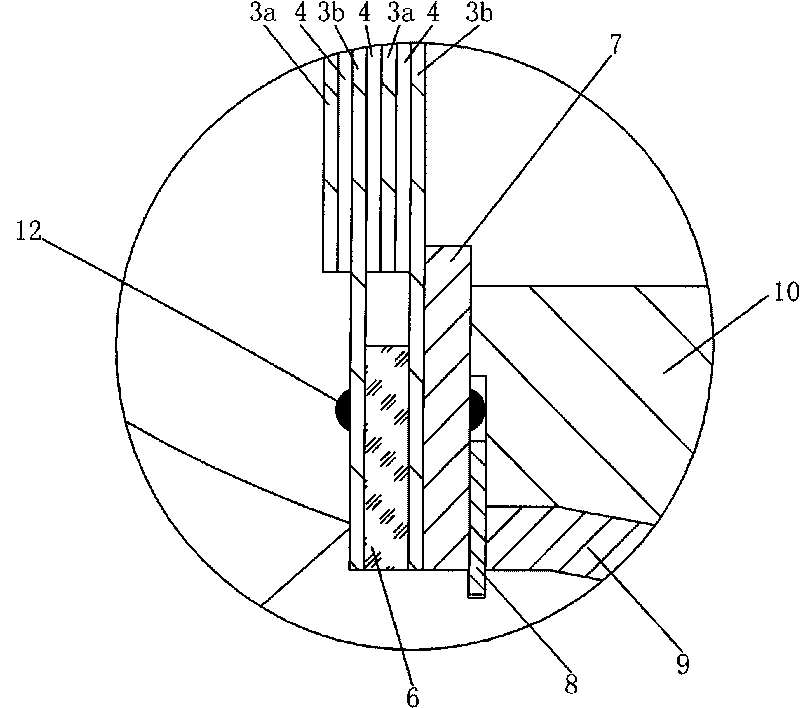

[0026] Figure 1-4 Shown, a specific embodiment of the present invention: a train wheel noise reduction damping device, its composition is: by at least two ring-shaped metal plates 3a, 3b and at least one ring-shaped viscoelastic damping layer 4 Alternately bonded and laminated to form a noise shielding plate; the outer periphery of the noise shielding plate is screwed on the rim 1a of the wheel 1 through the outer mounting ring 2, and the inner periphery is clamped on the hub 1c and the axle 1d through the clamp ring 10.

[0027] In this example, an inner mounting ring 7 , an elastic snap ring 8 and a rubber ring 9 are arranged in sequence between the inner circumference of the noise shielding plate and the clamp ring 10 .

[0028] The outer diameter of the viscoelastic damping layer 4 in this example is smaller than the inner diameter of the outer mounting ring 2, and the inner diameter is larger than the outer diameter of the inner mounting ring 7; there are four metal plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com