Washing machine

A washing machine and detergent technology, applied in the field of washing machines, can solve problems such as detergent residue, cost increase, and lifespan of seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

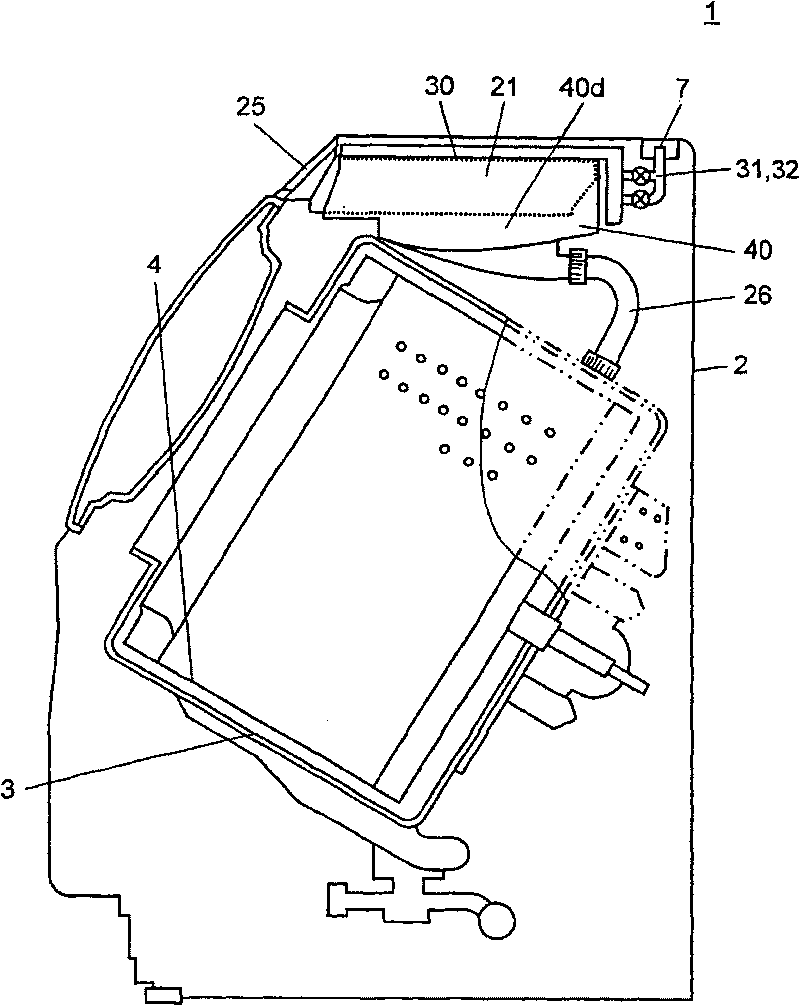

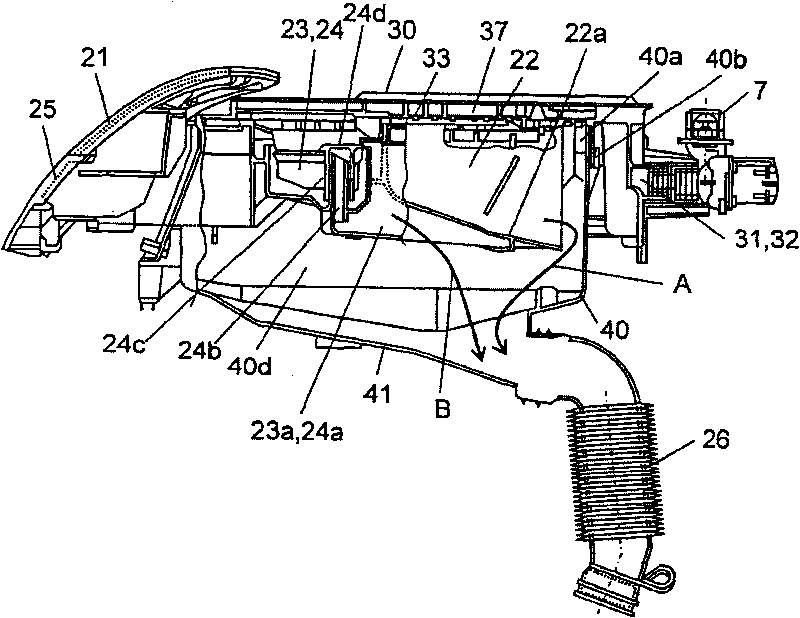

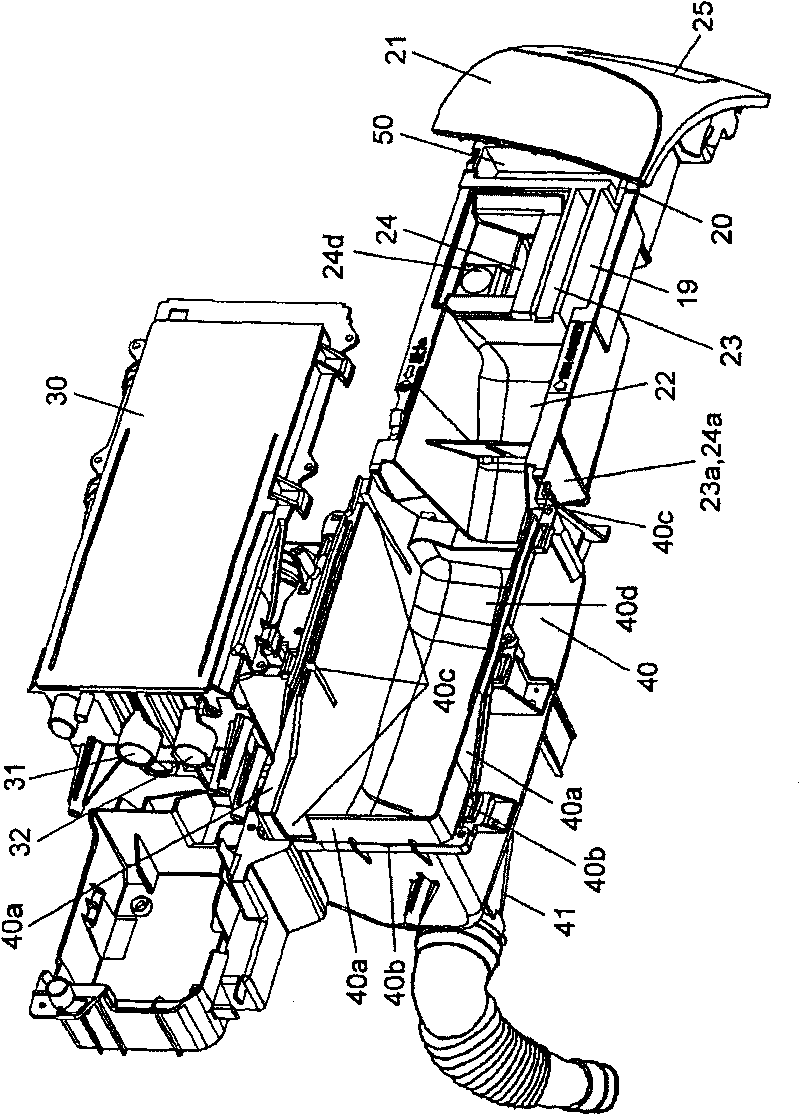

[0021] figure 1 It is a longitudinal sectional view of the washing machine in Example 1 of the present invention. exist figure 1 In the middle, the left is the front of the washing machine, figure 2 is a side sectional view of the housing portion of the detergent dispenser in the washing machine, image 3 It is an exploded oblique view of the shell part of the detergent dispenser in the washing machine.

[0022] like figure 1 As shown in , the washing machine 1 has a washing machine frame body 2, and a water holding cylinder 3 and a rotating drum 4 are arranged in the washing machine frame body 2. A detergent dispenser housing 40 is provided above the water storage cylinder 3, and the upper opening of the detergent dispenser housing 40 is a box body with a bottom surface and a cross-section roughly in the shape of "]". In addition, a water injection cover 30 is provided above the detergent dispenser housing 40 . The detergent storage container 21 is accommodated in t...

Embodiment 2

[0047] Use below Figure 5 The structure and operation of Embodiment 2 of the present invention will be described. For the sake of brevity, the description of the same parts as those in Embodiment 1 is omitted here, and only the different parts are described.

[0048] Figure 5 It is an exploded perspective view of the shell of the detergent dispenser of the washing machine in the second embodiment of the present invention, where the detergent storage container 21 is pulled out beyond the specified position and the water injection cover 30 is turned upside down. Oblique view.

[0049] like Figure 5 As shown in , a liquid detergent storage container 23 and a liquid softener storage device 24 are arranged in parallel in the detergent storage container 21 . In addition, in front of the liquid detergent storage container 23 and the liquid softener storage container 24 ( Figure 4 On the right side) and the handle 25, there is a concave recovery groove 50 with a bottom. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com