Method for damping vibrations acting on object to be protected e.g. building, involves partially absorbing static dead weight of vibrating mass by magnetic forces that act between elements of vibration damper

A shock absorber and function technology, which is applied in building components, building structure, shockproof and other directions, can solve the problems of high cost, bearing wear, adverse effects of frequency shock absorber damping shock absorber efficiency, etc., and achieves good adjustability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

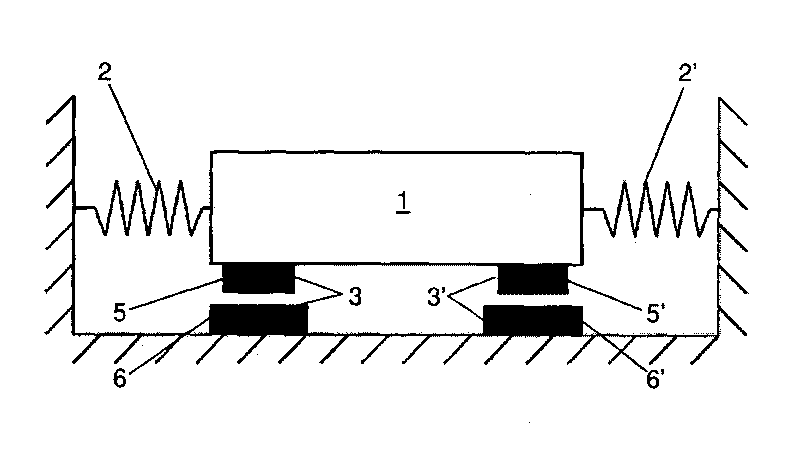

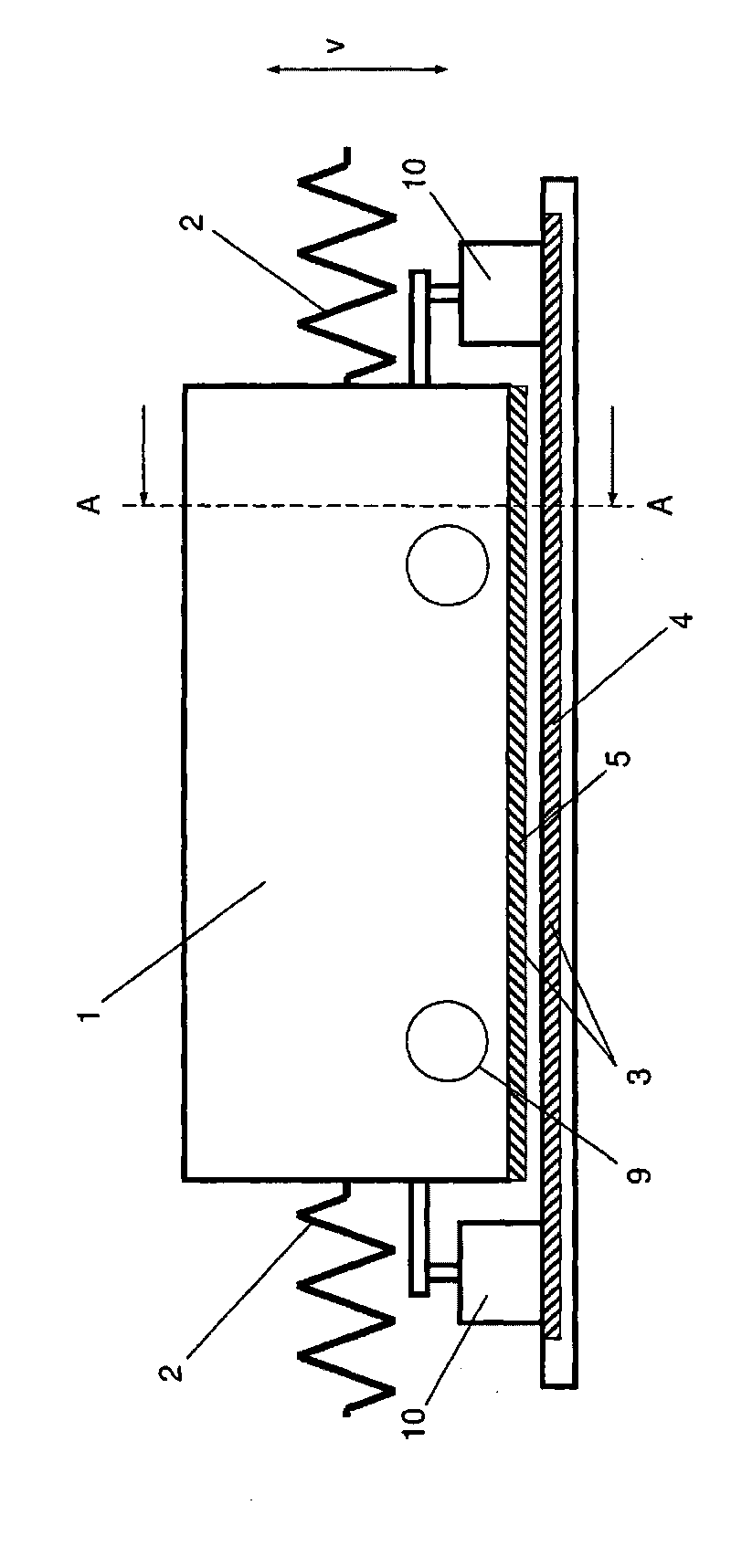

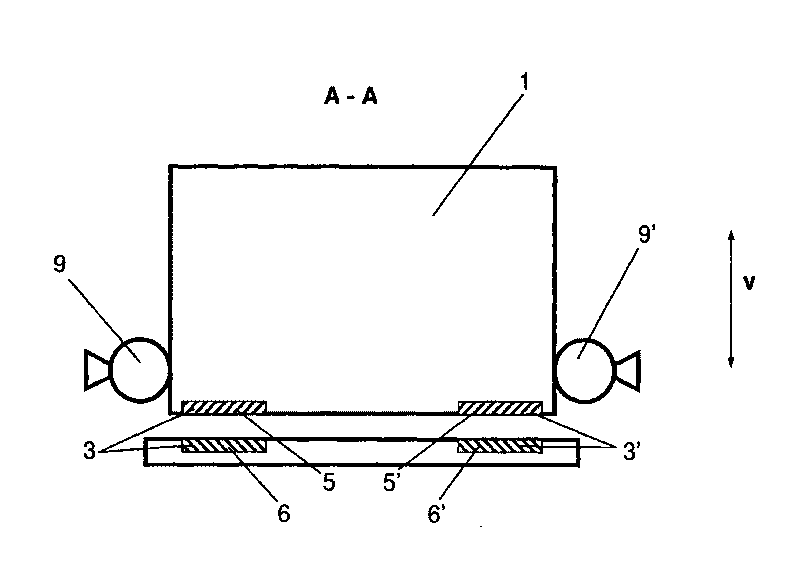

[0025] figure 1 It is a schematic diagram used to explain again the basic principle of the invention. Accordingly, the horizontally acting shock absorber according to the invention essentially comprises an inertial vibration mass 1 held between, for example, two oppositely arranged springs 2, 2' operating as tension or compression springs. Between them, the springs 2, 2' have a seat on each of the walls of a cavity, not shown in more detail, which accommodates the shock absorber and is formed in the object to be protected. During low-frequency vibrations, the static dead weight of seismic mass 1 can no longer be supported by the stiffness of springs 2 , 2 ′, which according to the invention is at least partially absorbed by magnetic mounts 3 , 3 ′. These magnetic supports are formed or arranged on the underside of seismic mass 1 in the schematic diagram shown. The current two magnetic supports 3, 3' each consist of a pair of magnets with a permanent magnet 5, 5' arranged dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com