Automobile brake drum with latticed stiffeners

A technology of automobile braking and grid strengthening, applied in the direction of brake drum, brake type, brake parts, etc., can solve the problems of automobile brake drum deformation, reduce friction coefficient, affect braking effect, etc., achieve fast heat dissipation, Effect of increasing strength and improving braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

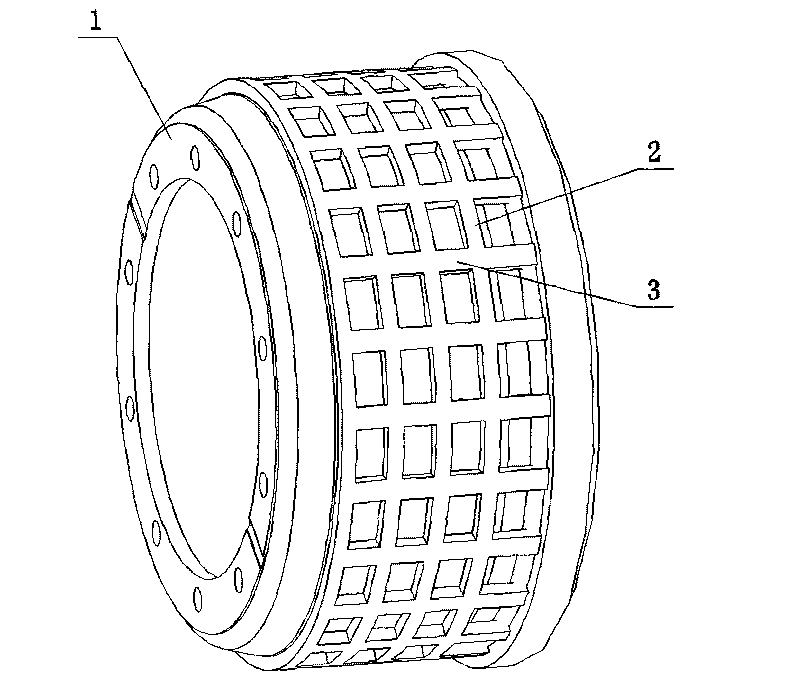

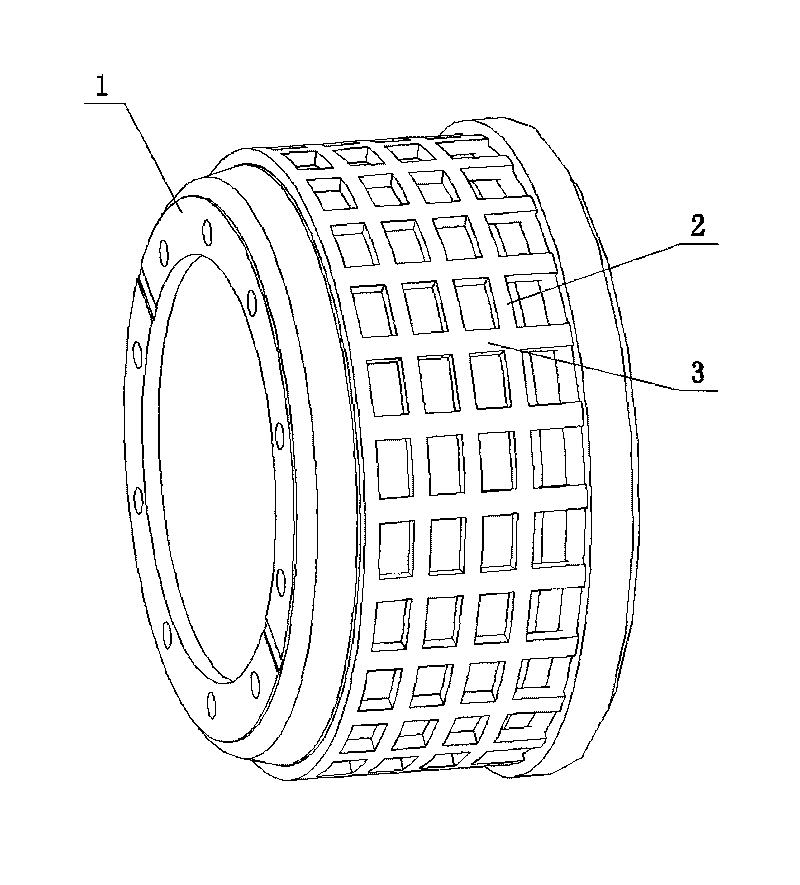

[0015] Such as figure 1 Shown, a kind of automobile brake drum with grid reinforcing rib, it comprises brake drum body 1, on the outer peripheral surface of brake drum drum body 1 is provided with grid-shaped reinforcing rib, and this grid-shaped reinforcing rib The ribs are composed of four annular reinforcing ribs 2 perpendicular to the axis of the brake drum body and twenty-four strip-shaped reinforcing ribs 3 parallel to the axis of the brake drum body.

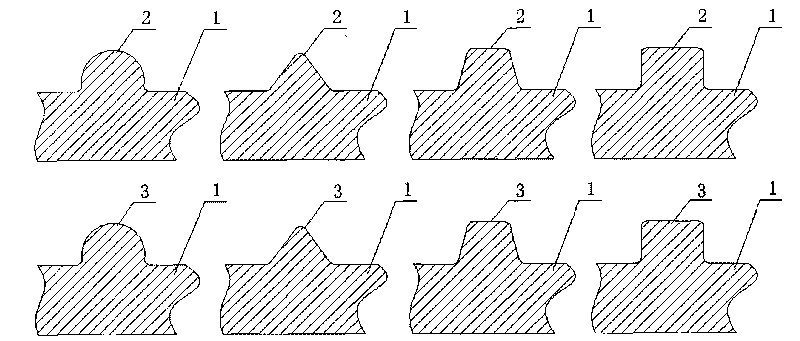

[0016] Such as figure 2 As shown, there are four cross-sectional shapes of the ring rib 2 and the strip rib 3 constituting the grid rib, and these four shapes are semi-circular, triangular, trapezoidal and rectangular respectively. In practice, these are only four commonly used shapes, and the protection scope of the main claims of the present invention is not limited to these shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com