Crossing angle and roll bending force reduction based roll shape design method of work roll of PC rolling mill

A technology of roll shape design and intersection angle, which is applied in metal processing equipment, rolls, calculations, etc., can solve the problems of shortening the roll changing cycle, low stability of the rolling mill, and accelerating the wear of the work roll surface, so as to improve the control of the plate crown ability, improve service life, and ensure the effect of quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

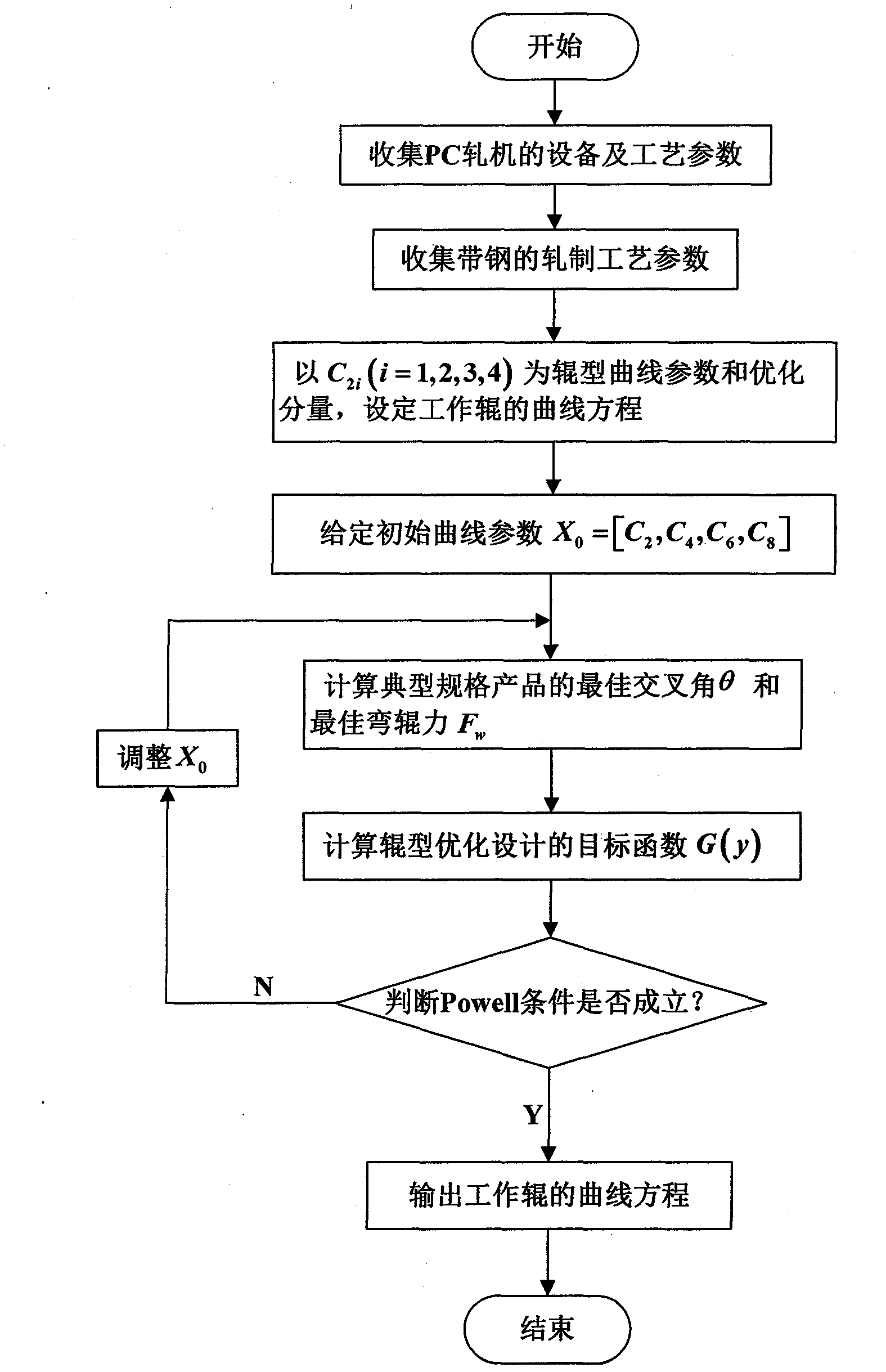

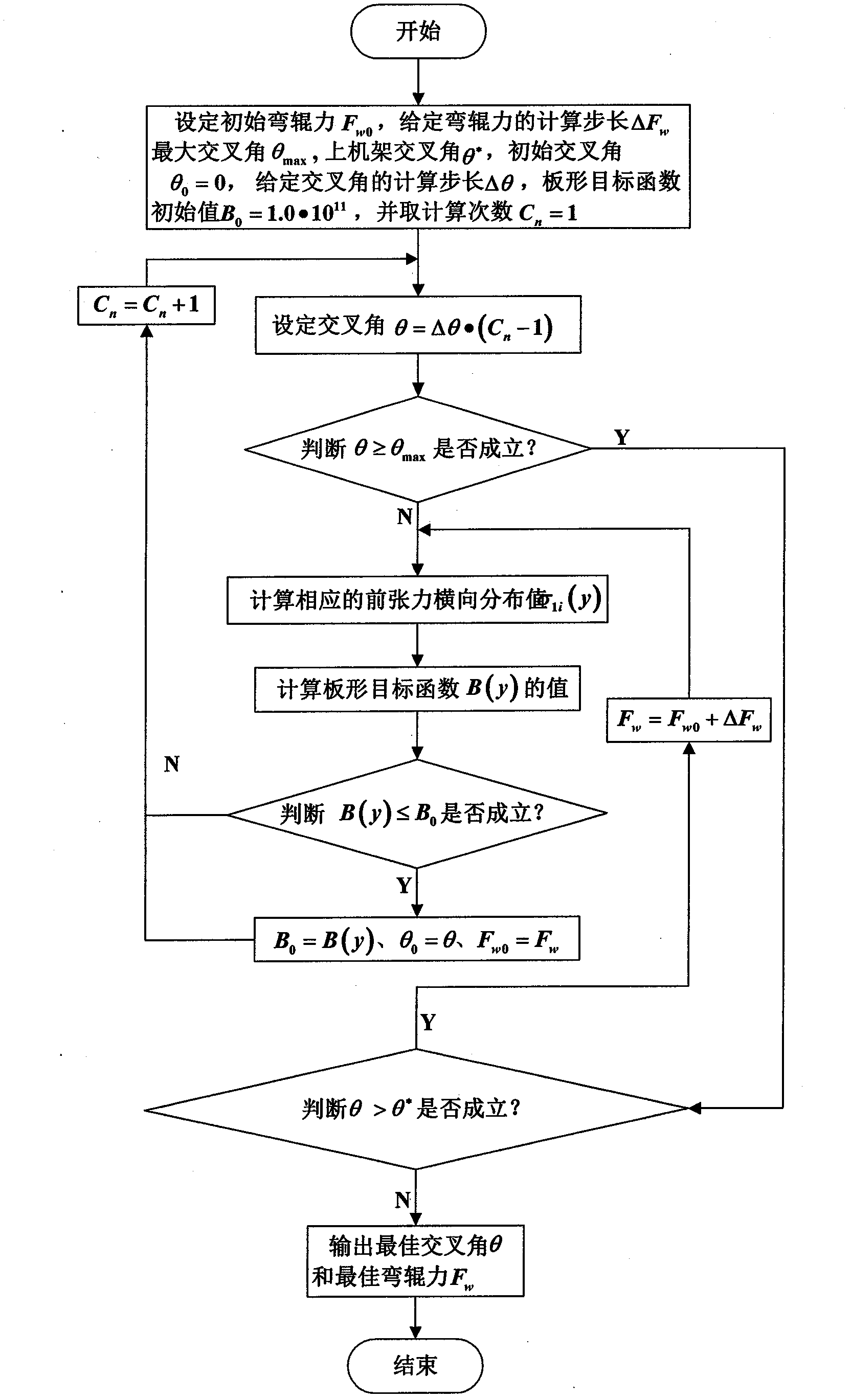

[0048] Provided below when adopting the method optimization design of the present invention to design a certain 1880PC hot continuous rolling mill finish rolling group rolling strip, the process of solving the work roll profile curve parameters of its fourth stand, as figure 1 shown, including the following steps:

[0049] (a) Collect PC mill equipment parameters and process parameters:

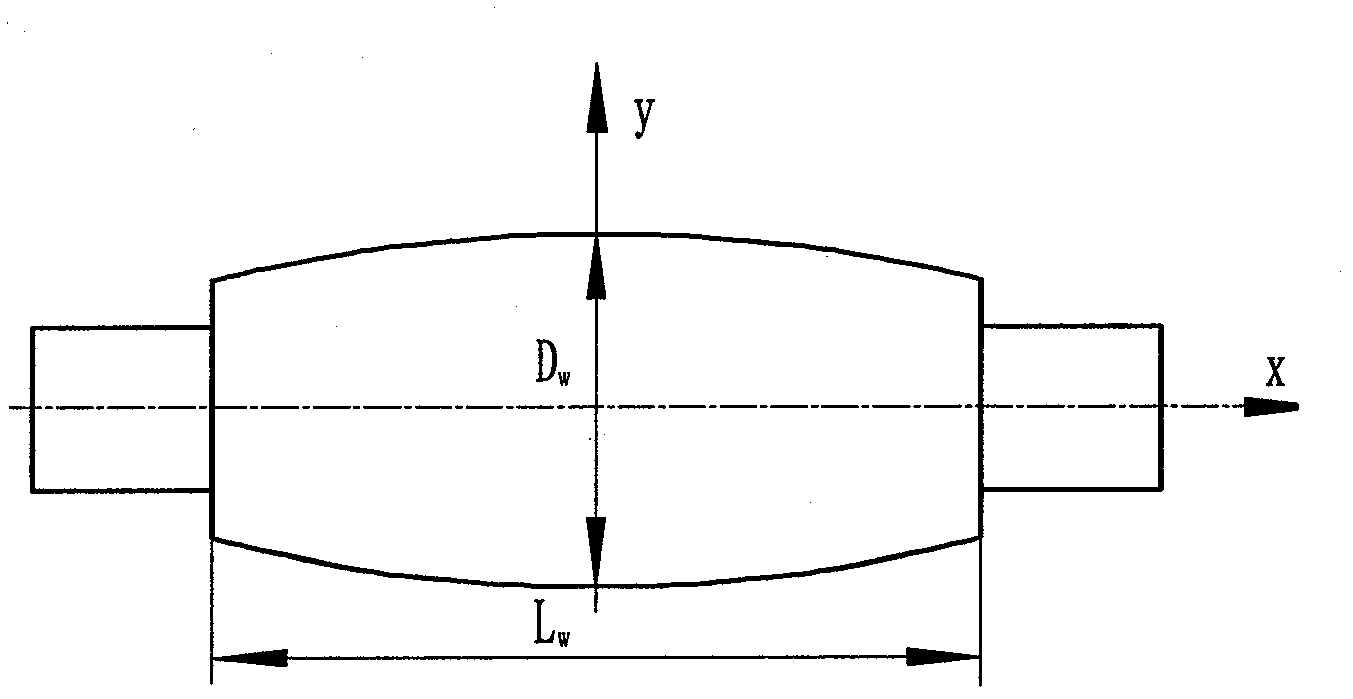

[0050] Work roll body length is 1880mm, roll body diameter is 785mm (835mm~735mm), roll neck diameter is 610mm, bending cylinder distance is 3080mm, elastic modulus is 175GPa, Poisson’s ratio is 0.25, and the rigidity of the stress-bearing parts of the single-chip frame outside the roll system is 3400kN / mm, maximum bending force ±1200kN;

[0051] (b) Collect the rolling process parameters of a certain typical strip steel, the specific data are as shown in Table 1:

[0052] Table 1 A typical strip steel parameters

[0053]

[0054] (c) with C 2i For the roll shape curve parameters and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com