Double-manipulator interactive lug forming device

A technology of double manipulators and forming devices, applied in the direction of electrode manufacturing, electrical components, circuits, etc., can solve problems such as easy deformation, offset, failure to send out, welding deflection, etc., to ensure relative position accuracy, prevent tabs from bending, Solve the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

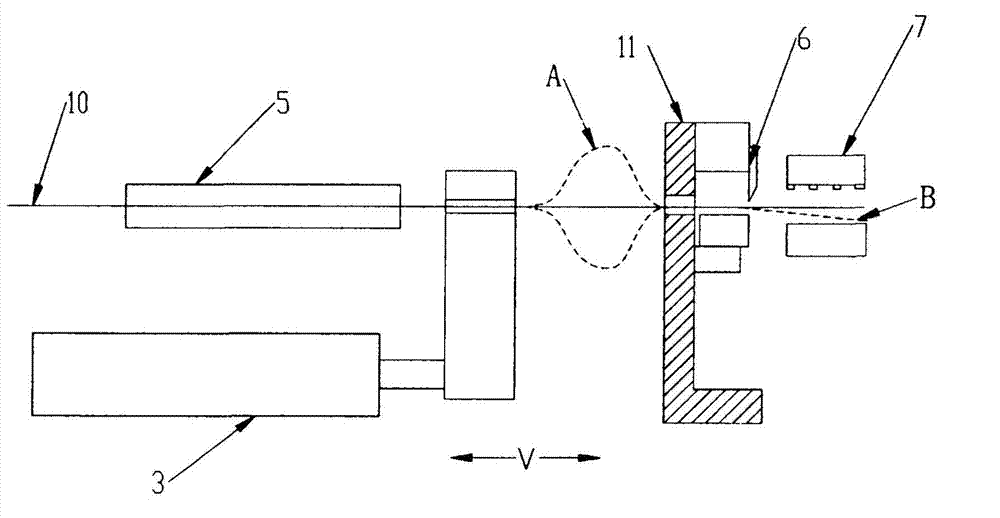

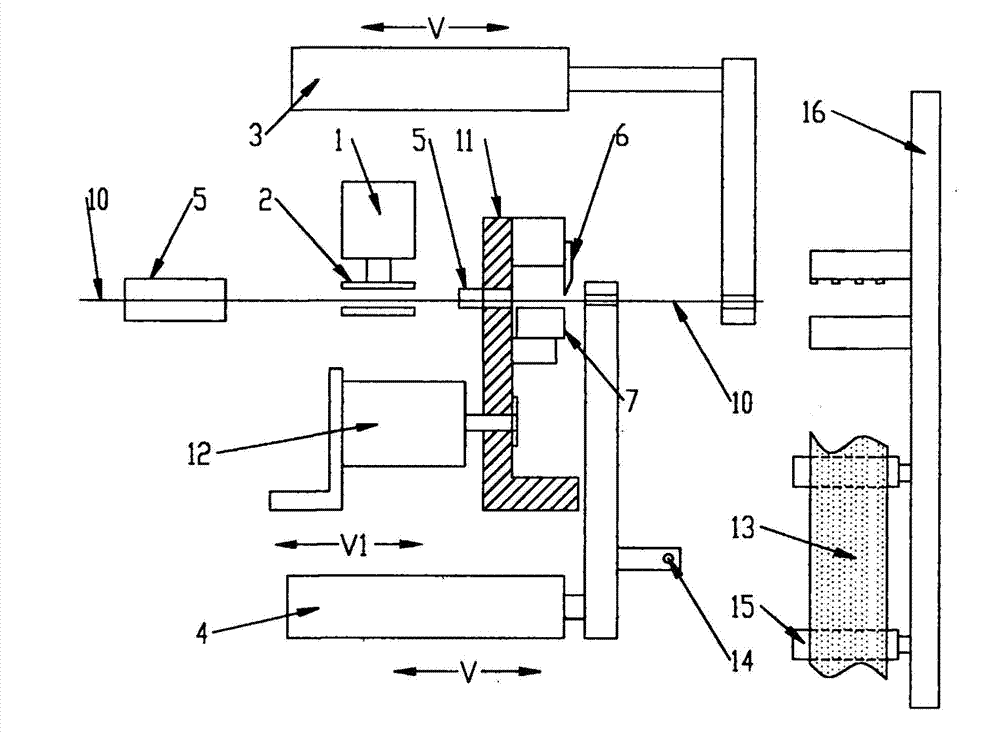

[0020] like figure 2 Shown: a dual-manipulator interactive tab forming device of the present invention includes a tab pulling manipulator 3, a tab feeding manipulator 4, a tab cutting knife 6, and a welding machine die 7, characterized in that: the polar tab The front end of the ear cutter 6 is installed with a tab pulling manipulator 3 and a tab feeding manipulator 4 , and a tab pressing plate 2 controlled by the tab pressing cylinder 1 is installed at the back of the tab cutting knife 6 .

[0021] A laser sensor 14 is also installed at the front of the tab feeding manipulator 4 , which controls the stop position of the tab feeding manipulator 4 by sensing the edge of the pole piece 13 .

[0022] The pole ear cutter 6 includes an upper cutter and a lower cutter, and is fixedly installed on the pole ear cutter holder 11. The ear cutter moving cylinder 12 controls the movement.

[0023] The operation process of the device of the present invention is as follows: when the tab ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com