Saw guide

A guide device and hand saw technology, which is applied in the direction of sawing machine device, measuring device, mitering working device, etc., can solve the problems of inflexibility, saw blades biting and scratching each other, difficulty in hand saw guide device, etc., and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

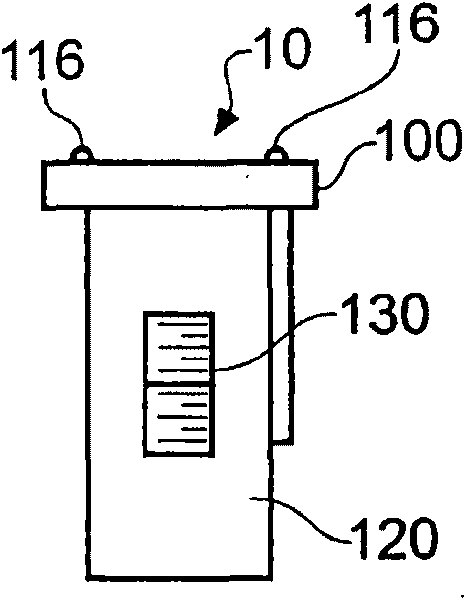

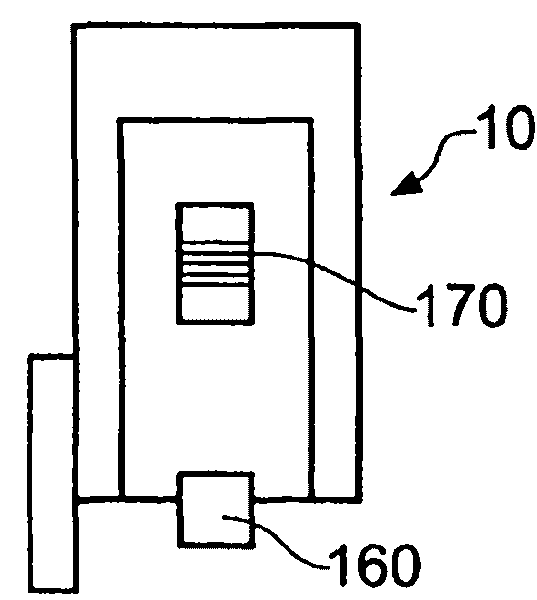

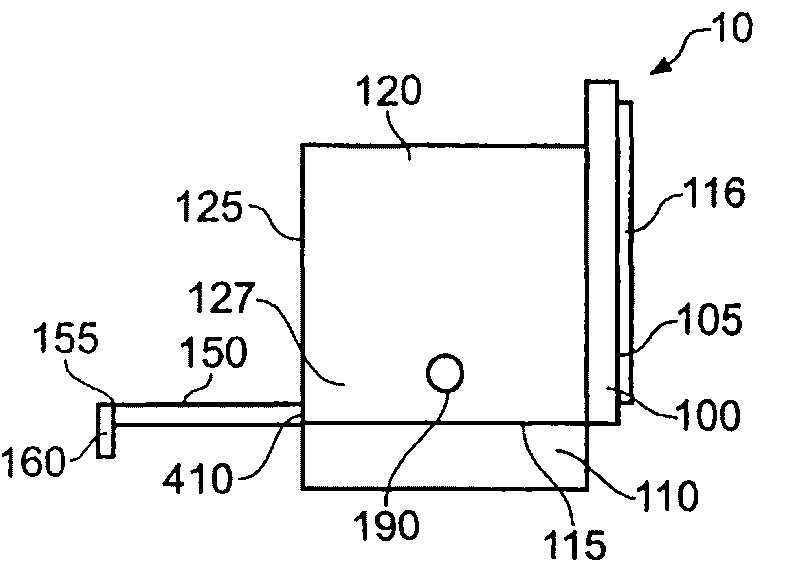

[0084] According to a preferred embodiment of the present invention, the hand saw guide 10 includes a guide plate 100 with a guide surface 105 and a base 110 with a base surface 115 mounted on a housing 120 . Both the guide surface 105 and the base surface 115 are perpendicular to each other and face away from the housing 120 . When the base surface 115 and the surface 200 of the workpiece 220 to be cut ( Figure 6 ) are engaged, the guide surface 105 extends across the surface of the cut material at the front position of the housing 120, so that the cutting member 300 that is in face-to-face contact with the guide surface 105 is guided during the cutting process of the workpiece 220.

[0085] The housing 120 houses a tape measure 150 which is drawn out from the rear end surface 125 of the housing 120 in a rearward direction away from the guide plate 100 . The free end 155 of the tape measure 150 is provided with a lip 160 which fits over an edge 260 of a workpiece. The free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com