Method for producing dietary fiber with by-product orange dreg of orange juice

A dietary fiber and orange pomace technology, applied in food preparation, food science, application and other directions, can solve the problems of insufficient refinement of production, low product quality, product impact, etc., to achieve a comprehensive product structure, improve product profits, and avoid resources. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

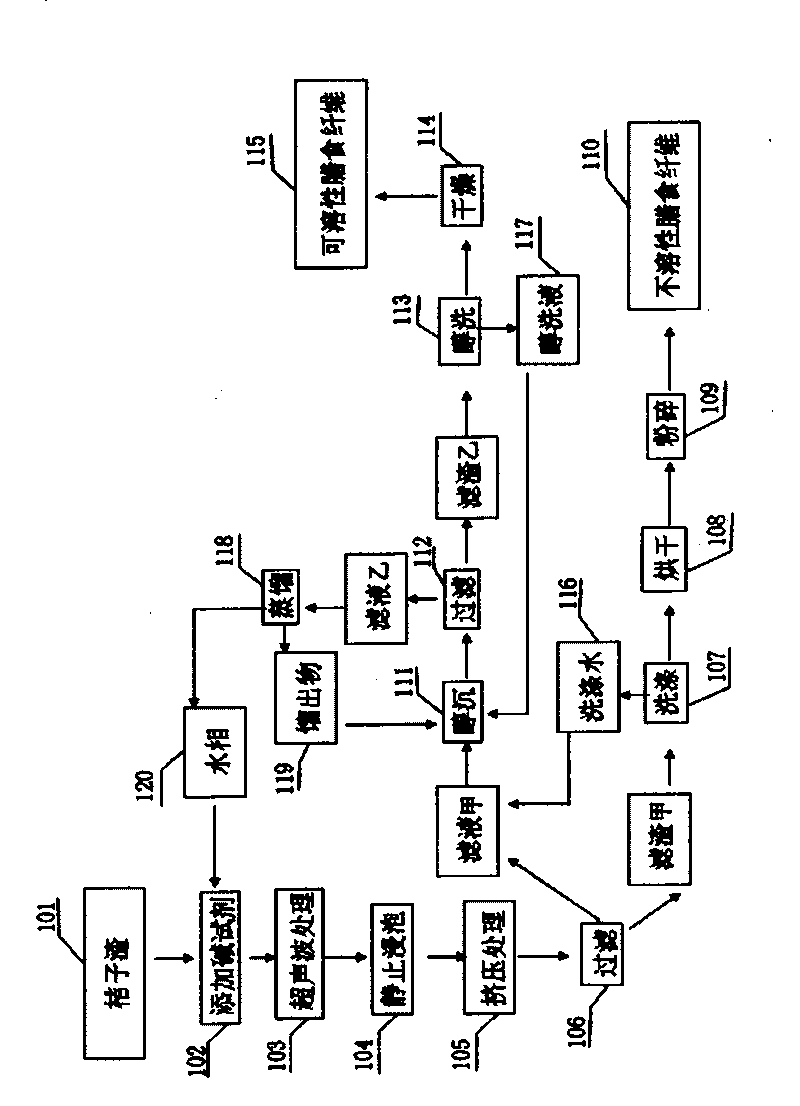

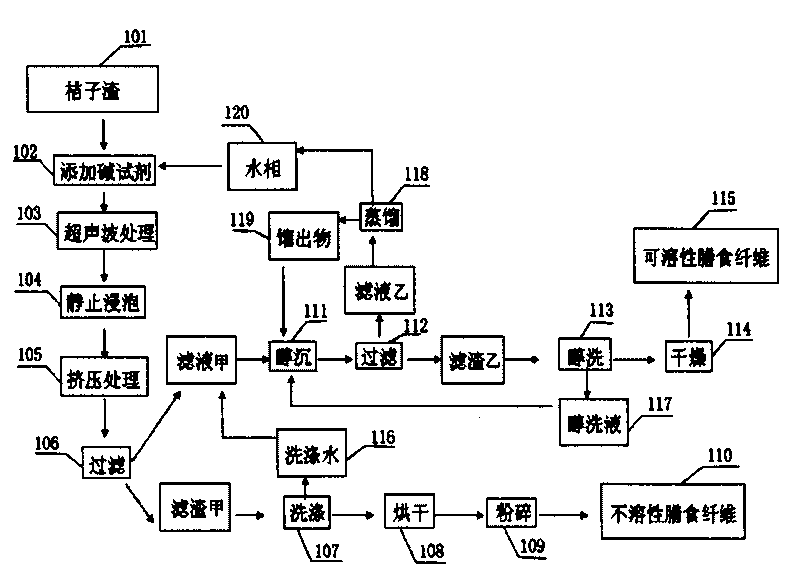

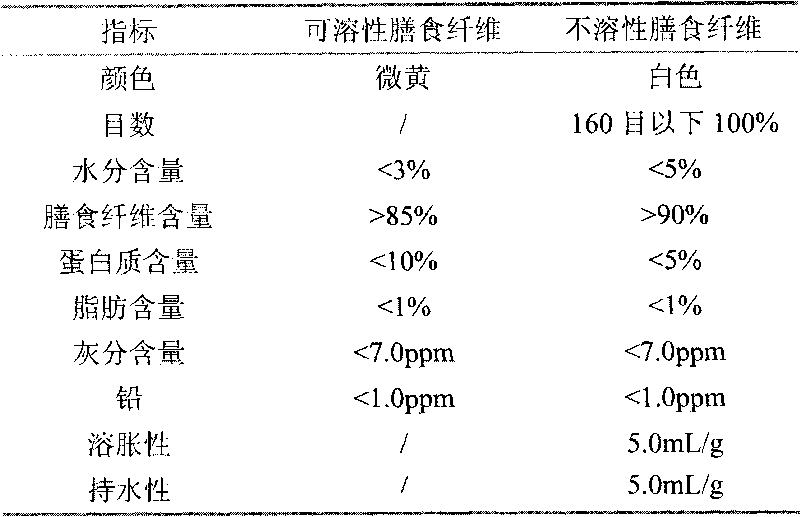

Method used

Image

Examples

Embodiment 1

[0042] Add alkaline solution to orange dregs. The alkali solution is 10% sodium hydroxide, and the amount added is 15 times that of orange dregs. The orange pomace after adding alkali is treated with ultrasonic for 10min to cause sonic cavitation between the alkali solution and the orange pomace, increase the contact area between the orange pomace and the alkali solution, and increase the transfer rate of soluble substances into the alkali solution. After ultrasonic treatment, the material is soaked for 1 hour and then transferred to the next step.

[0043] The soaked orange pomace is then processed by a single screw extruder.

[0044] Then it is filtered to separate the filter residue A and the filtrate A. The filter residue A is washed with a small amount of water to recover the soluble substances carried into the filter residue, and the washing water is incorporated into the filtrate A.

[0045] Perform alcohol precipitation. Add 4 times of absolute ethanol to the filtrate A, ...

Embodiment 2

[0053] The orange pomace is added to the alkali solution. 15% sodium hydroxide is selected as the lye, and the amount added is 16 times that of orange dregs. The orange pomace after alkali addition was treated with ultrasound for 20 minutes. After ultrasonic treatment, the material is soaked for 2 hours and then transferred to the next step.

[0054] The soaked orange pomace is then processed by a single screw extruder.

[0055] Then it is filtered to separate the filter residue A and the filtrate A. The filter residue A is washed with a small amount of water, and the washing water is incorporated into the filtrate A.

[0056] Perform alcohol precipitation. Add 4 times of absolute ethanol to the filtrate A, stir evenly, and filter after standing for a period of time. Filter to obtain filtrate B and filter residue B.

[0057] The filtrate B is distilled to obtain a distillate and an aqueous phase. The distillate ethanol is reused for alcohol precipitation. The water phase is reu...

Embodiment 3

[0064] Add alkaline solution to orange dregs. The alkali solution is 12% sodium hydroxide, and the amount added is 15 times that of orange dregs. The orange pomace after adding alkali is treated with ultrasonic for 15min to cause sonic cavitation between the alkali solution and the orange pomace, increase the contact area between the orange pomace and the alkali solution, and increase the transfer rate of soluble substances into the alkali solution. After ultrasonic treatment, the material is soaked for 1.5 hours and then transferred to the next step.

[0065] The soaked orange pomace is then processed by a single screw extruder.

[0066] Then it is filtered to separate the filter residue A and the filtrate A. The filter residue A is washed with a small amount of water to recover the soluble substances carried into the filter residue, and the washing water is incorporated into the filtrate A.

[0067] Perform alcohol precipitation. Add 4 times of absolute ethanol to the filtrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com