Method and device for washing industrial dust

A technology for cleaning devices and dust, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems such as inability to guarantee cleanliness, waste of resources and space, secondary pollution, etc., and achieve two The possibility of secondary pollution is small, saving resources and space, and the effect of good cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and in conjunction with preferred embodiments.

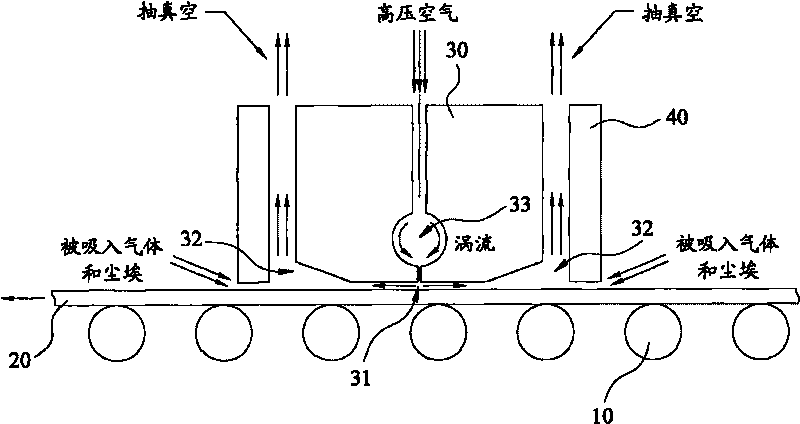

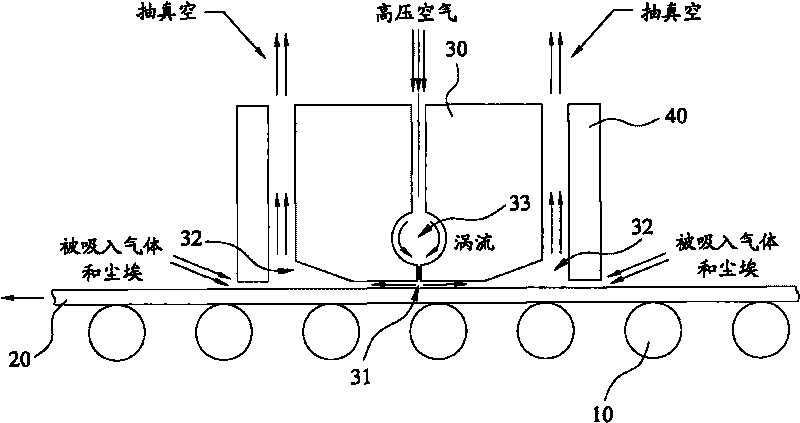

[0020] The industrial dust cleaning method of the present invention uses a vortex formed by a high-pressure gas to sweep the surface of the workpiece, and then uses a vacuum port to suck away the dust purged by the vortex. So as to achieve the purpose of cleaning the surface of the workpiece. The device according to the method of the present invention is described below.

[0021] figure 1 The structure of the device for cleaning industrial dust using gas according to the present invention is schematically shown. As shown in the figure, the industrial dust cleaning device using gas according to the present invention includes a vortex generating device 30, a cover 40, a vacuuming device (not shown in the figure), and a conveying device 10 for conveying workpieces to be cleaned.

[0022] The conveying device 10 is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com