Cascading continuous stamping die used for manufacturing fixed panel of automobile door hinge

A technology for automobile doors and stamping dies, which is applied to manufacturing tools, perforating tools, forming tools, etc., can solve the problems that the wall thickness of the screw holes of the screw plate of the vehicle door fails to meet the technical requirements, the qualified rate of finished products is low, and the production cost is high, and the labor force is improved. Productivity, assurance requirements, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

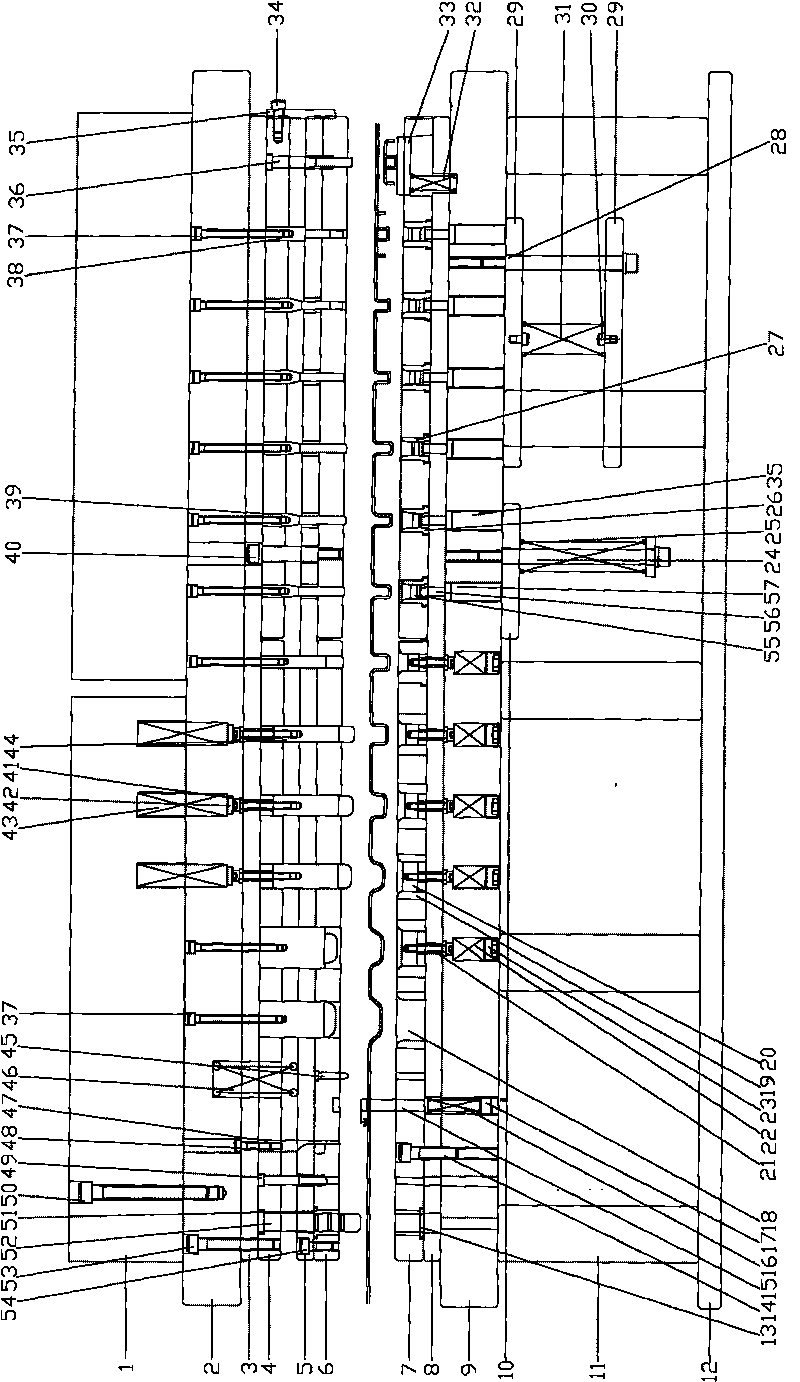

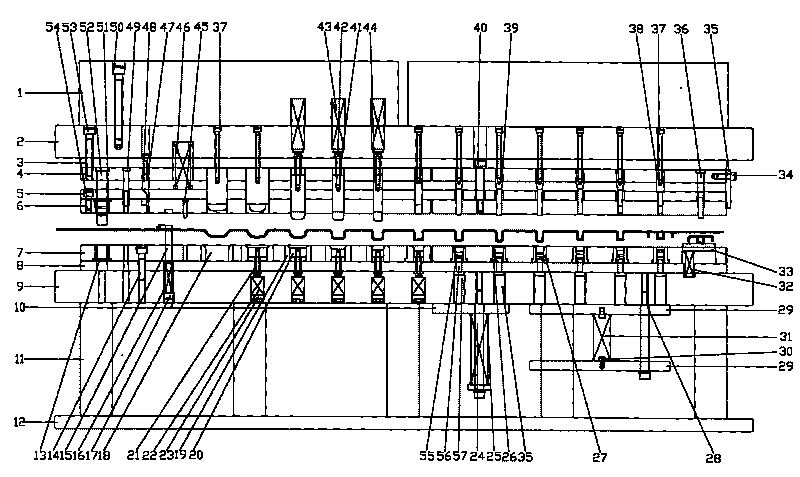

[0014] See figure 1 , the present invention comprises an upper mold structure and a lower mold structure, and the upper mold structure and the lower mold structure are aligned and guided by a guiding structure, and a waste cutting knife 35 is installed on the upper mold structure, and the corresponding upper mold structure and the lower mold structure A punching structure, a stretching structure, and an upsetting structure are correspondingly installed in the mold hole.

[0015] The upper mold structure includes an upper mold base 2, which is installed on the upper pad 1 through screws 50, and the lower part of the upper mold base 2 is sequentially installed with an upper backing plate 3 and a fixed plate 4 through screws 53; the upper mold structure also includes a stopper plate 5 and stripper plate 6; stopper plate 5 and stripper plate 6 are fixed by screws 54; Contour sleeve connection; the lower mold structure includes a lower mold base 9, the lower mold base 9 is support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com