Five-DOF (degree of freedom) redundance driving hybrid mechanism suitable for vibration reduction

A technology of hybrid mechanism and degree of freedom, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc. It can solve problems such as strong motion coupling, easy to generate singularity, and small working space, and achieve high flexibility, easy control, and mobile Effects decoupled from rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

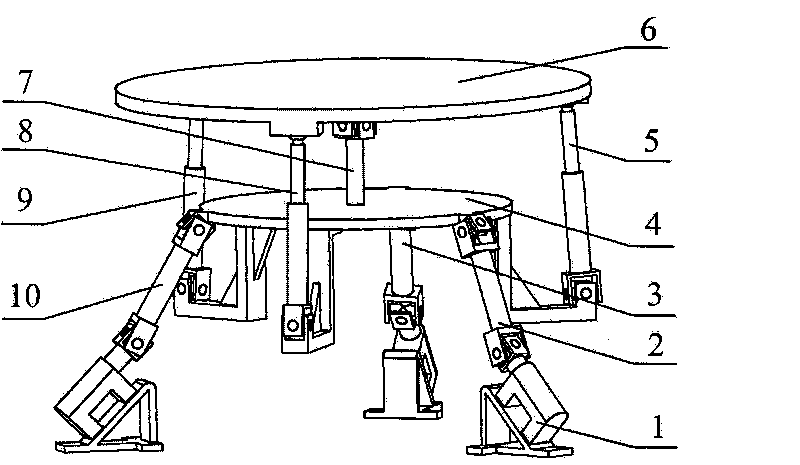

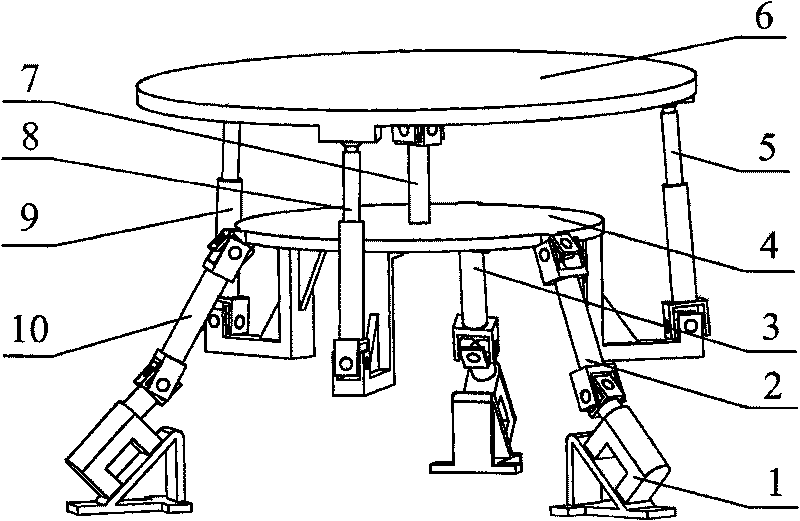

[0012] The general structure of the embodiment of the present invention is as figure 1 shown. The hybrid mechanism is composed of a fixed platform 1, an intermediate platform 4, a moving platform 6, a branch connecting the intermediate platform 4 and the fixed platform 1, and a branch connecting the moving platform 6 and the intermediate platform 4. The middle platform 4 is connected with the fixed platform 1 through three identical structures 2, 3, 10, each branch has a movable rod as a driving pair, the driving rod is connected with a fixed-length rod through a universal hinge, and the fixed-length rod The other end is connected to the intermediate platform 4 through a universal joint, and the mechanism realizes the three-dimensional movement of the intermediate platform 4 relative to the fixed platform 1 by controlling the position of the driving pair during the movement. The moving platform 6 is connected to the middle platform 4 through three active branches 5, 8, 9 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com