Compound initiating agent for polymerization reaction and application thereof

A composite initiator and polymerization technology, applied in the field of organic chemistry, can solve the problems of unsatisfactory ultraviolet blocking effect, no technical prompts, low initiator efficiency, etc., to reduce steric hindrance, widen the absorption range, The effect of improving the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

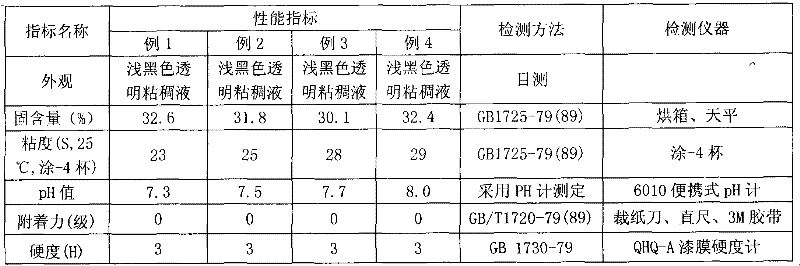

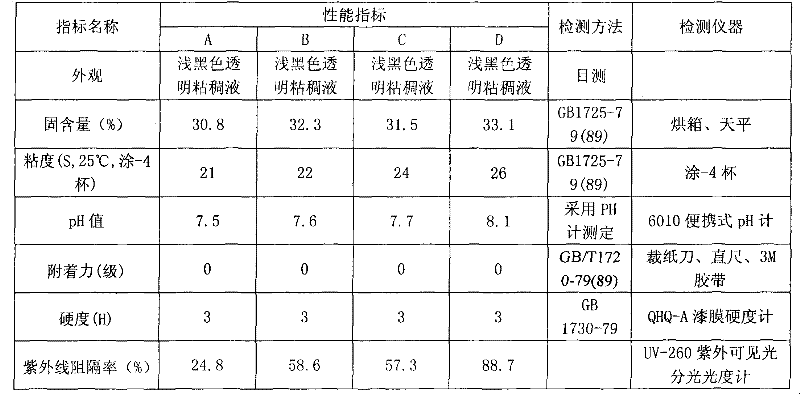

Examples

example 1

[0015] 1. Preparation of the composite initiator of the present invention: uniformly mix 30% of cobalt acetate, 30% of benzoyl peroxide and 40% of azobisisonitrile.

[0016] 2. Preparation of nano-fullerene modified acrylic polymer:

[0017] Add 55g of n-butanol, 0.6g of polyoxyethylene ether, 1g of fullerene and 1g of composite initiator into the reactor, stir, and heat to 85°C to obtain mixture A; mix 9g of methacrylic acid, 11g of hydroxymethacrylate, 11g of hydroxyethyl methacrylate, 25g of methyl methacrylate, 33g of butyl acrylate and 21g of styrene were placed in a head tank and mixed uniformly to obtain mixture B. Raise the temperature of the reactor to 85°C, start to drop the mixture B in the elevated tank, control the temperature in the reactor to 100±3°C during the dropwise addition, finish the dropwise addition in about 4.5 hours, and continue the constant temperature reaction at 100±3°C for 3 hours Finally, titration with iodometric method showed that the iodine ...

example 2

[0021] 1. Preparation of the composite initiator of the present invention: 28% of cobalt acetate, 40% of benzoyl peroxide and 32% of azobisisonitrile are uniformly mixed.

[0022] 2. Preparation of nano-fullerene modified acrylic polymer:

[0023] 58g of n-butanol, 0.7g of polyoxyethylene ether 1g and 1.4g of composite initiator fullerene were added to the reactor, stirred, and heated to 90°C to obtain mixture A; 11g of methacrylic acid, 12g of hydroxypropyl acrylate and Put 26g of methyl methacrylate, 32g of butyl methacrylate, and 21g of acrylonitrile into the head tank and mix evenly to obtain mixture B. Raise the temperature of the reactor to 100±3°C, start to drop the mixture B in the elevated tank, control the temperature in the reactor to be 100±3°C during the dropwise addition, finish the dropwise addition in about 4 hours, and continue the constant temperature reaction at 100±3°C After 4 hours, titration with iodometric method showed that the iodine value was 0.025, ...

example 3

[0027] 1. The preparation of the composite initiator of the present invention: 32% of cobalt acetate, 33% of benzoyl peroxide and 45% of azobisisonitrile are uniformly mixed to obtain final product.

[0028] 2. Preparation of nano-fullerene modified acrylic polymer:

[0029] 59g of n-butanol, 0.8g of polyoxyethylene ether, 1g of fullerene and 1.7g of the composite initiator of the present invention were added to the reactor, stirred, and heated to 90°C to obtain mixture A; Ester, 27g methyl methacrylate, 34g butyl acrylate, and 21g isobutyl methacrylate were put into a head tank and mixed uniformly to obtain mixture B. Raise the temperature of the reactor to 100±3°C, start to drop the mixture B in the elevated tank, control the temperature in the reactor to be 100±3°C during the dropwise addition, complete the dropwise addition in about 4 hours, and continue the constant temperature reaction at 100±3°C 4 Hours later, titration with iodometric method showed that the iodine val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com