Water-based fingerprint-resistant coating with interpenetrating network structure for galvanized steel sheet

A technology of interpenetrating network structure and galvanized steel sheet, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of discoloration and peeling of the film, improve the density, reduce the steric hindrance, and improve the salt spray resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

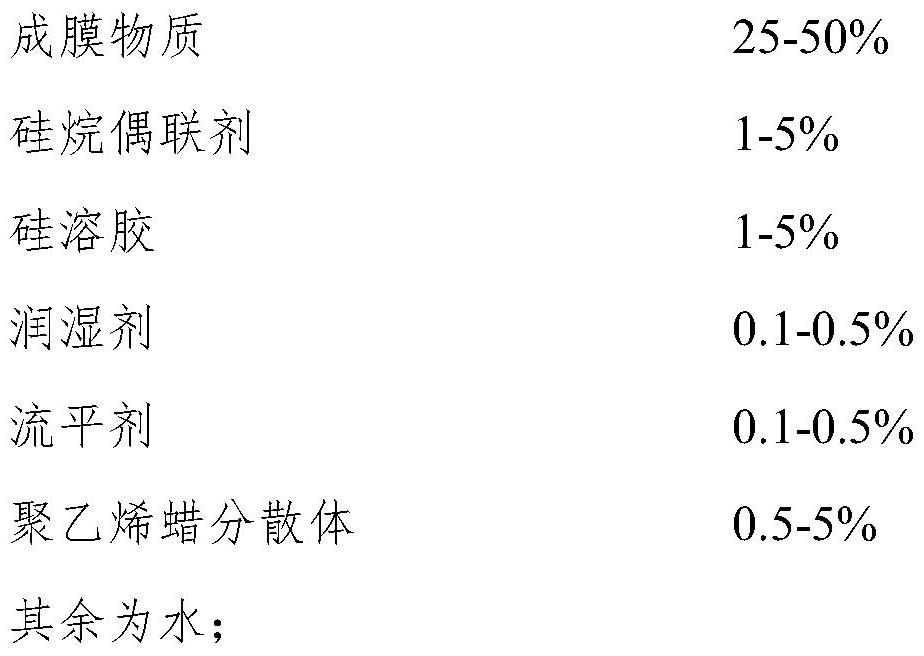

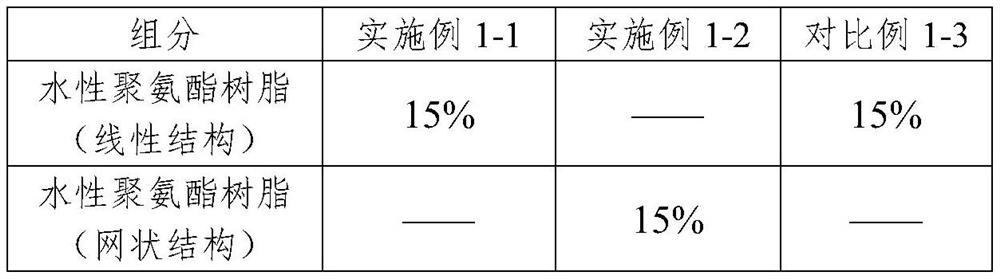

[0034] A water-based anti-fingerprint coating for galvanized steel sheets with an interpenetrating network structure, comprising 15% of water-based polyurethane resin, 25% of water-based acrylic resin, 1% of silane coupling agent, 1% of silica sol, 0.1% of wetting agent, leveling 0.1% of the agent, 0.5% of the polyethylene wax dispersion, and the rest is water. Under this component distribution ratio, the structural composition of water-based polyurethane resin and water-based acrylic resin is shown in Table 1 below.

[0035]

[0036]

[0037] Table 1

Embodiment 2

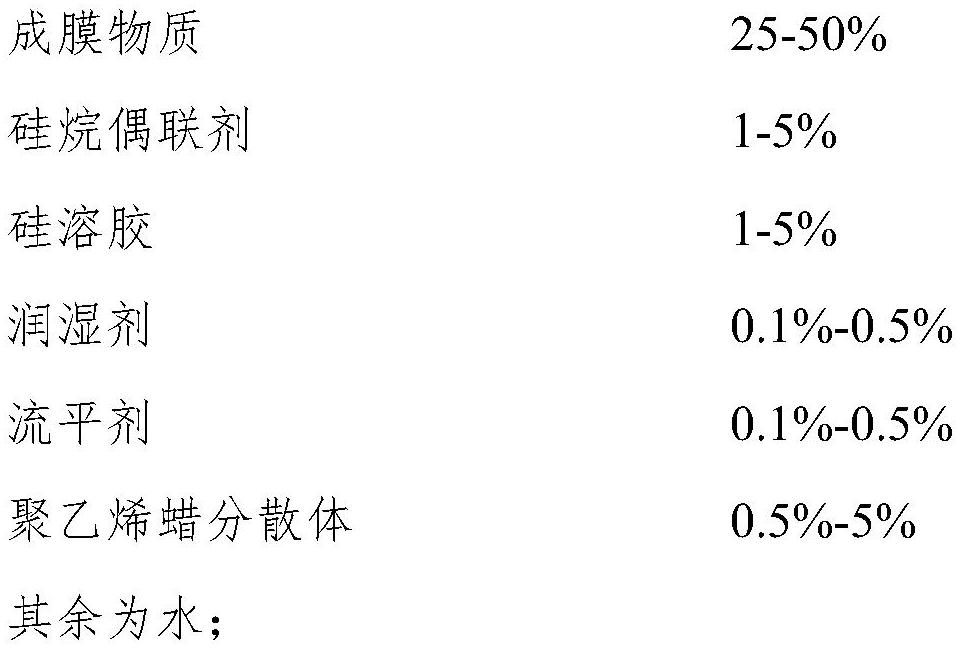

[0039] A water-based anti-fingerprint coating for galvanized steel sheets with an interpenetrating network structure, comprising 25% of water-based polyurethane resin, 15% of water-based acrylic resin, 3% of silane coupling agent, 3% of silica sol, 0.3% of wetting agent, leveling 0.3% of the agent, 2.5% of the polyethylene wax dispersion, and the rest is water. Under this component distribution ratio, the structural composition of water-based polyurethane resin and water-based acrylic resin is shown in Table 2 below.

[0040]

[0041] Table 2

Embodiment 3

[0043] A water-based anti-fingerprint coating for galvanized steel sheets with an interpenetrating network structure, including 30% water-based polyurethane resin, 20% water-based acrylic resin, 5% silane coupling agent, 5% silica sol, 0.5% wetting agent, leveling Agent 0.5%, polyethylene wax dispersion 5%, the rest is water. Under this component distribution ratio, the structural composition of water-based polyurethane resin and water-based acrylic resin is shown in Table 3 below.

[0044]

[0045]

[0046] table 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com