A method for improving the efficiency of poplar wood enzymatic hydrolysis

A poplar enzymatic and enzymatic hydrolysis technology is applied in the field of biomass pretreatment and enzymatic hydrolysis, which can solve the problems of inhibiting cellulase hydrolysis ability, low enzymatic hydrolysis efficiency, and large amount of cellulase used, so as to reduce space obstacles. The effect of function, simple process and stable hydrolysis ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for improving poplar enzymatic hydrolysis efficiency, comprising the following steps:

[0040] Step 1) Preprocessing

[0041] 1.1) Mix 60 mL of acetic acid with a purity of 99% and 60 mL of hydrogen peroxide with a purity of 30%, add a catalytic amount of 100 mmol / L sulfuric acid, and mix well to prepare an acetic acid hydrogen peroxide pretreatment solution;

[0042] 1.2) Weigh 10 grams of dry poplar wood residue after acetic acid pretreatment and place it in a polytetrafluoroethylene-lined steel cylinder, add acetic acid hydrogen peroxide solution with a volume concentration of 100% according to the ratio of solid to liquid ratio of 1:10, and place it at 60°C to Pretreatment at 80°C for 2 hours; the above-mentioned acetic acid pretreatment refers to adding acetic acid with a purity of 5% to poplar and treating it at 170°C for 30 minutes;

[0043] 1.3) After the pretreatment, cool down, use a centrifuge to separate the solid and liquid, collect the filter res...

Embodiment 2

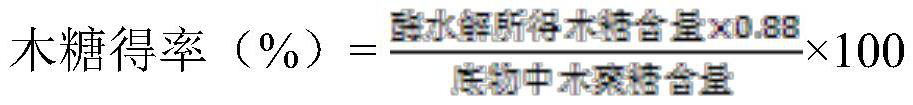

[0055] The pretreatment method and reaction conditions are basically the same as in Example 1, the difference is that the volume concentration of the acetic acid hydrogen peroxide solution in the acetic acid hydrogen peroxide pretreatment is 80%; if only 20FPU cellulase is added during hydrolysis, the calculated glucose yield is 67.2% , The yield of xylose was 72.4%. After adding 500nkat of β-glucosidase per gram of substrate, the yield of glucose hydrolyzed by the enzyme is increased to 91.1%, and the yield of xylose is increased to 94.9%.

Embodiment 3

[0057] The pretreatment method and reaction conditions are basically the same as in Example 1, the difference is that in the enzymatic hydrolysis process, 1000nkat of β-glucosidase is added per gram of substrate, and the final glucose yield is 97.5%, and the xylose yield is 99.7% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com