Decelerator and mounting structure of decelerator to object machine

A technology of reduction gear and installation structure, which is applied in the direction of mechanical equipment, engine seals, engine components, etc., can solve the problems of embedding operation difficulty, wear, and setting size difference, etc., and achieve the effect of simplifying embedding and maintenance and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, an example of an embodiment of the present invention will be described in detail with reference to the drawings.

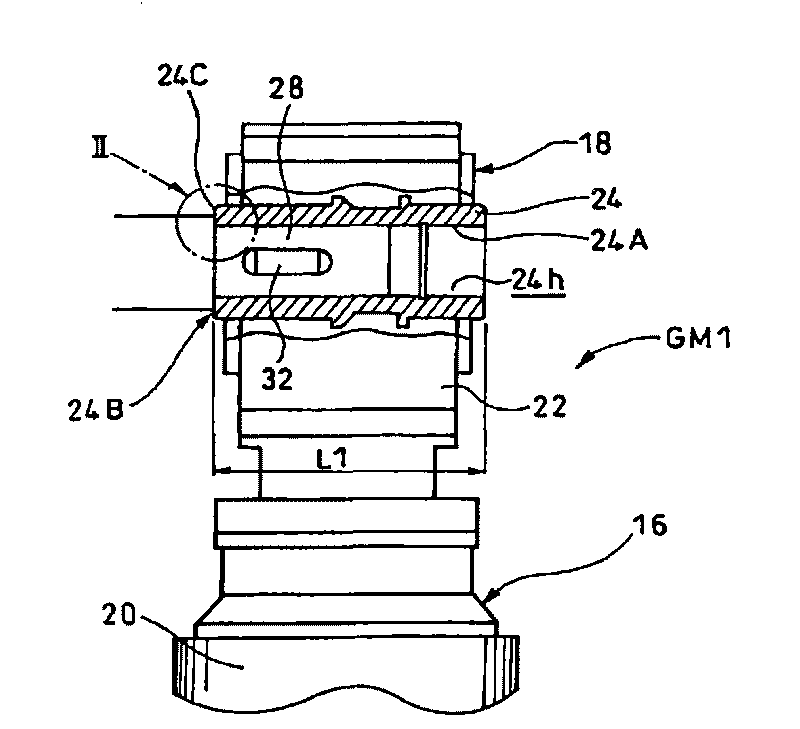

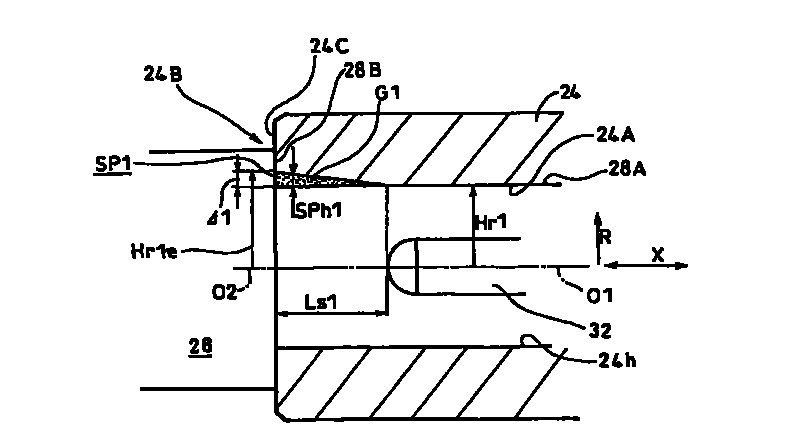

[0019] figure 1 It is a partial schematic plan cross-sectional view showing an example of a geared motor (reduction gear) to which an embodiment of the present invention is applied. figure 2 It is the enlarged sectional view of the II part.

[0020] This geared motor GM1 is mainly composed of a motor 16 and a speed reducer 18 . The motor 16 includes a motor case 20 , and the speed reducer 18 includes a speed reduction case 22 . A hollow output shaft 24 is rotatably supported by the speed reduction case 22 .

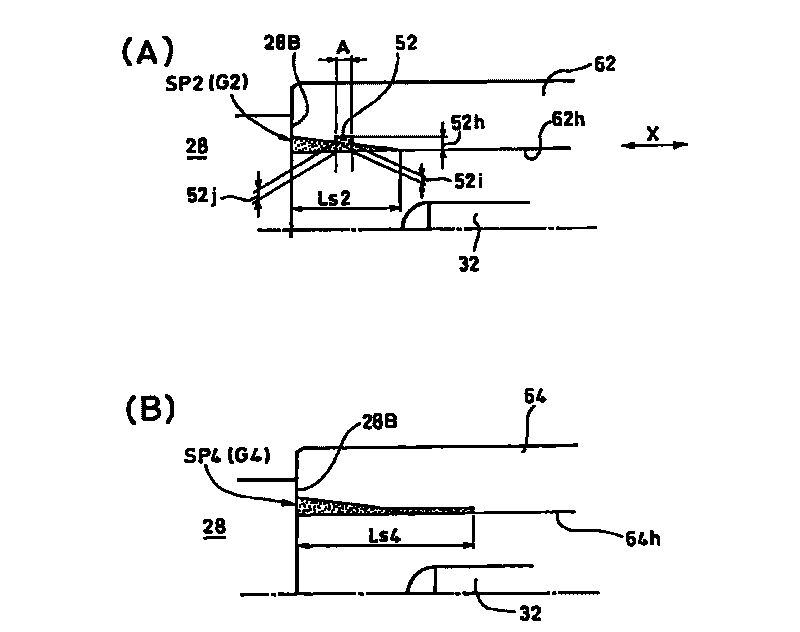

[0021] The output shaft 24 has a through hole 24h into which a driven shaft 28 such as a transmission device (target machine: not shown) is inserted. The power transmission between the output shaft 24 and the driven shaft 28 is performed by "formal engagement" via the key 32 , that is, by a structure that has a clearance and is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com