Condensing range hood

A range hood, condensing technology, applied in the field of range hoods, can solve problems such as polluting the environment, high temperature of the oil fume mixture, and reducing the service life of the range hood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

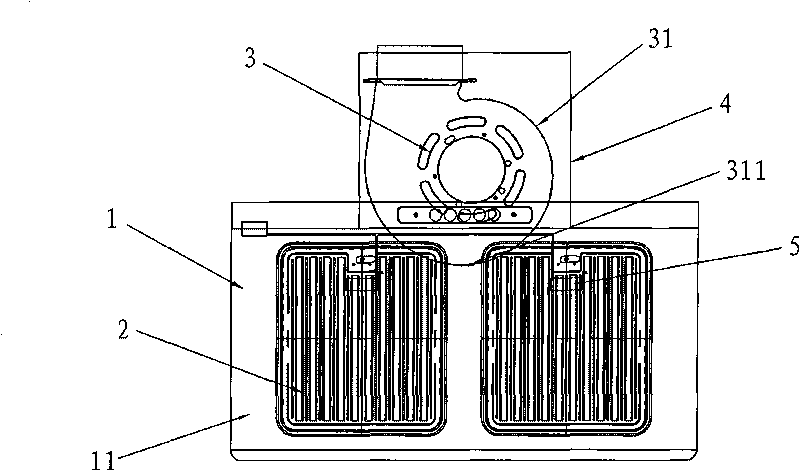

[0020] Such as figure 1 , figure 2 As shown, a condensing range hood includes a housing 1, a separation net 2, a centrifugal fan 3 and a control device. The housing 1 is composed of a front panel 11, two side panels, a rear panel and a top panel 12. The separation net 2 is set On the air inlet of the front panel 11, there is an oil collecting tank 11 at the bottom of the front panel 11; diagram 2-1 As shown, there is an oil drip hole 311 on the centrifugal fan housing 31; a coaming plate 4 is arranged on the top plate 12, and the centrifugal fan 3 is installed in the coaming plate 4;

[0021] Described refrigerating device is made of semiconductor refrigeration sheet 5;

[0022] The semiconductor cooling plate 5 is arranged on the separation net 2 and is located on the inner surface of the separation net 2 .

Embodiment 2

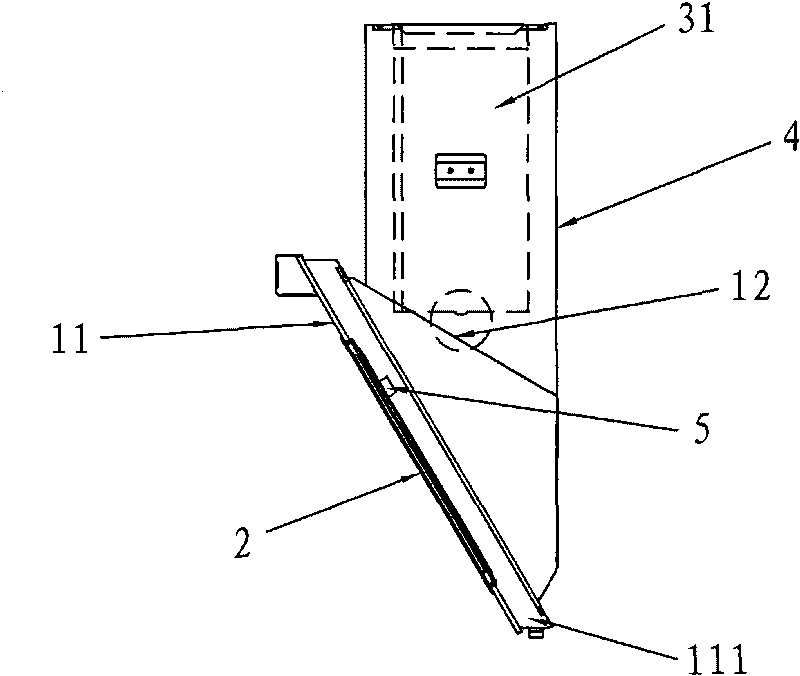

[0024] Such as image 3 , Figure 4 as shown,

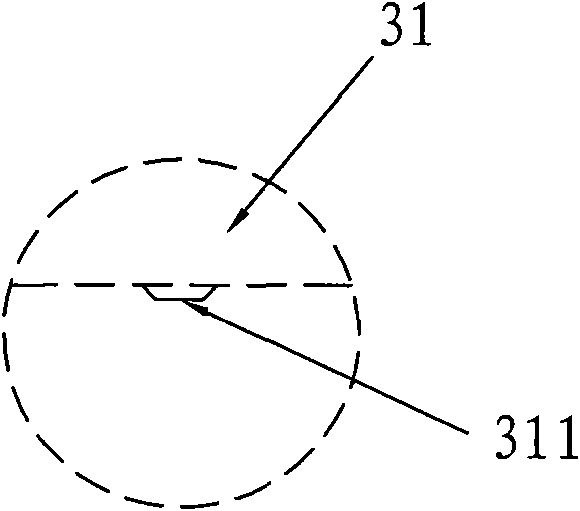

[0025] A semiconductor cooling plate 5 is arranged in the centrifugal fan casing 31, above the oil drip hole 311, and the cooling surface is opposite to the oil drip hole.

[0026] As a further improvement of this embodiment, another semiconductor cooling plate 5 is arranged on the surface of the separation net 2 in the casing, and the cooling surface is opposite to the separation net 2 .

Embodiment 3

[0028] Such as Figure 5 , Figure 6 As shown, the refrigerating device is composed of a semiconductor cooling plate 5 and a cooling tube 6, the cooling tube 6 is bent into a fence shape, and the fence-shaped part 61 of the cooling tube 6 is bonded to the separation net 2; One end of the tube 5 cooperates with the cooling surface of the semiconductor cooling plate 5 , and the other end is open; the heating surface of the semiconductor cooling plate 5 communicates with the outside of the housing 1 .

[0029] A further improvement of this embodiment is that the open end of the cooling pipe 6 extends into the centrifugal fan casing 31 from the oil drip hole 311 of the centrifugal fan casing 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com