No-load cutting-in modeling and experimental method of double-fed type wind-driven generator

A wind power generator, doubly-fed technology, applied in the direction of electrical digital data processing, single-network parallel feeding arrangement, special data processing application, etc., can solve the problem of no-load grid connection verification and lack Accuracy, can not be externally connected to the verification of actual control equipment and other issues, to achieve a real and accurate simulation environment, and improve the effect of verification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

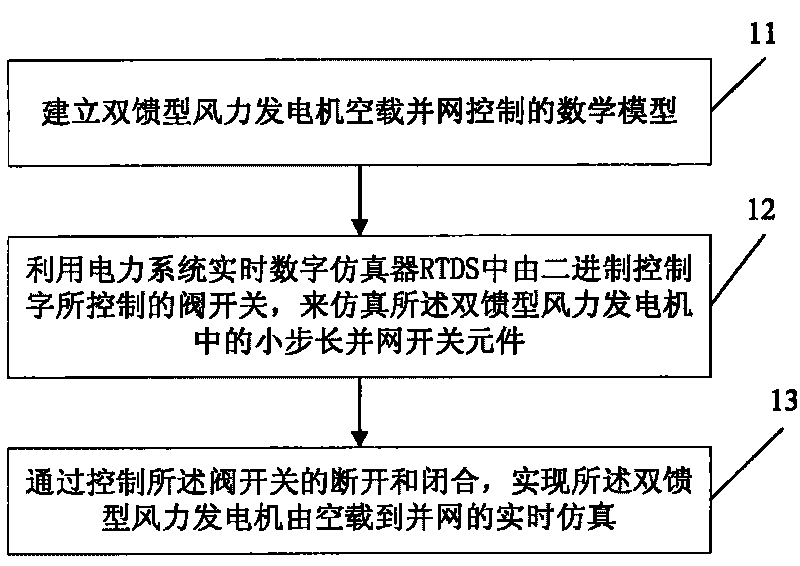

[0026] The embodiment of the present invention provides a method for modeling and experimenting the no-load grid-connected doubly-fed wind power generator. In order to better describe the embodiment of the present invention, the specific embodiment of the present invention will now be described in conjunction with the accompanying drawings, as shown in figure 1 Shown is a schematic flow chart of the no-load grid-connected modeling of the doubly-fed wind turbine provided by the embodiment of the present invention, and the method includes:

[0027] Step 11: Establish a mathematical model for no-load grid-connected control of doubly-fed wind turbines.

[0028] In this step 11, a mathematical model for no-load and grid-connected control of the doubly-fed wind power generator is established by establishing the transfer function of the doubly-fed wind power generator no-load and grid-connected.

[0029] In the specific implementation process, the double-fed wind power generation con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com