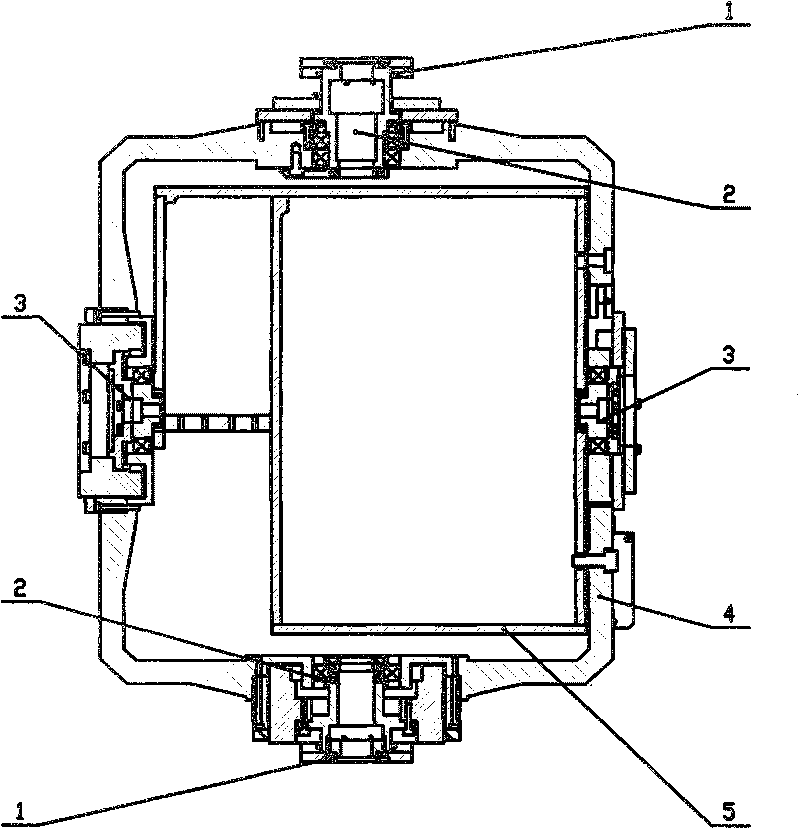

Moment motor driving shafting module for inner frame of airborne photoelectric platform

A torque motor and drive shaft technology, applied in electromechanical devices, electric components, electrical components, etc., can solve the problems of increasing the volume and impact of the inner frame, and achieve the effects of compact structure, reduced impact, and strong practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

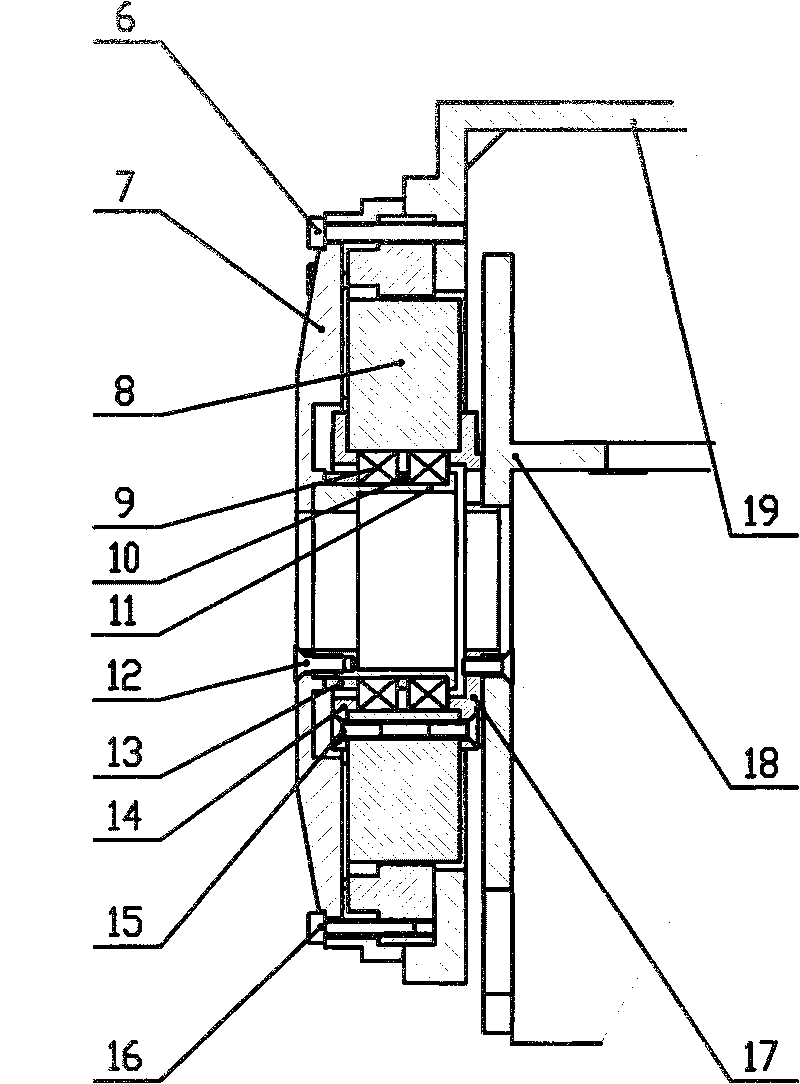

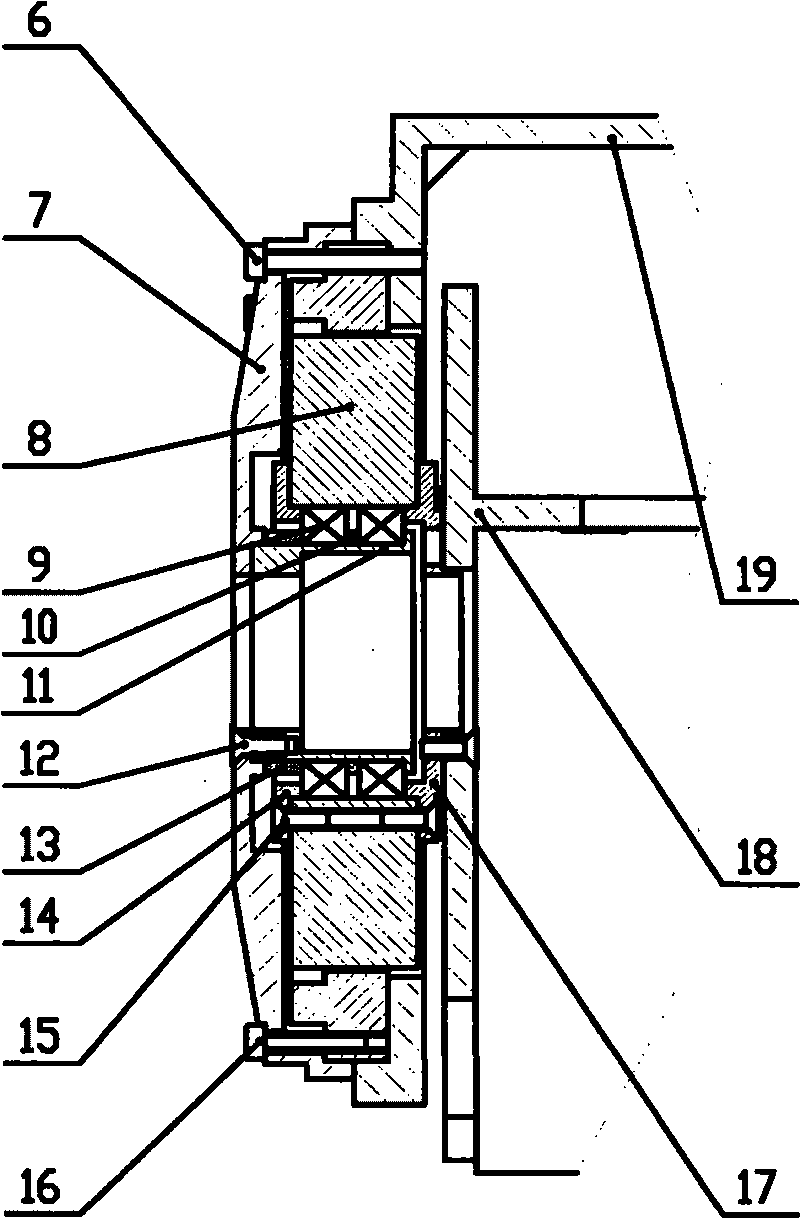

[0013] The invention according to figure 2 The structure shown is implemented. Wherein the motor seat 7 and the first spacer ring 10 and the second spacer ring 13 are aluminum alloy material 7A09, the hollow shaft 11 and the motor output shaft 17 are steel 45#, and the torque motor 8 and the bearing 9 are purchased parts. The assembly process is as follows: fasten the output shaft 17 of the motor to one end of the mover of the torque motor 8 with the second countersunk head screw 15; add the first spacer ring 10 in the middle of a pair of bearings 9, the inner ring of the bearing is connected with the hollow shaft 11, and the outer ring of the bearing Connect with the inner hole of the torque motor 8 mover; use the pressure ring 14 to press the outer ring of the bearing to apply pre-tightening force to eliminate the shafting clearance, and tighten it with the second countersunk screw 15; use the first countersunk screw 12 to connect the motor base 7 and Hollow shaft 11, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com