Moon-exploration mechanical arm modularization joint based on absolute position measurement

A modular joint and absolute position technology, which is applied in manipulators, program-controlled manipulators, aerospace equipment, etc., can solve the problems of not being able to directly provide global feedback of joint position information, cumbersome signal fusion and fusion algorithms, etc. Effects of electromagnetic interference and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

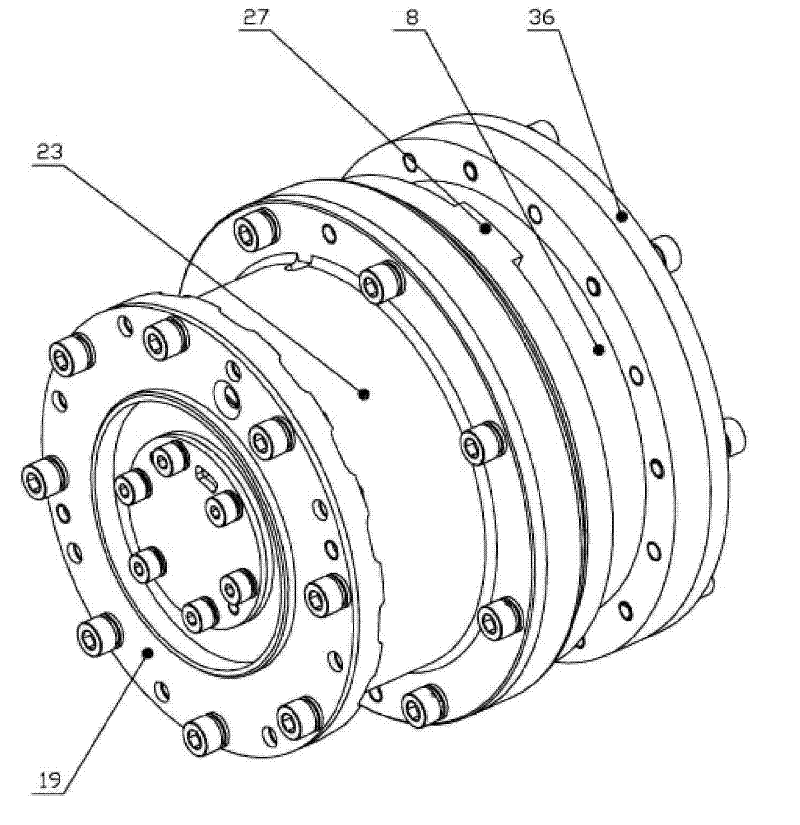

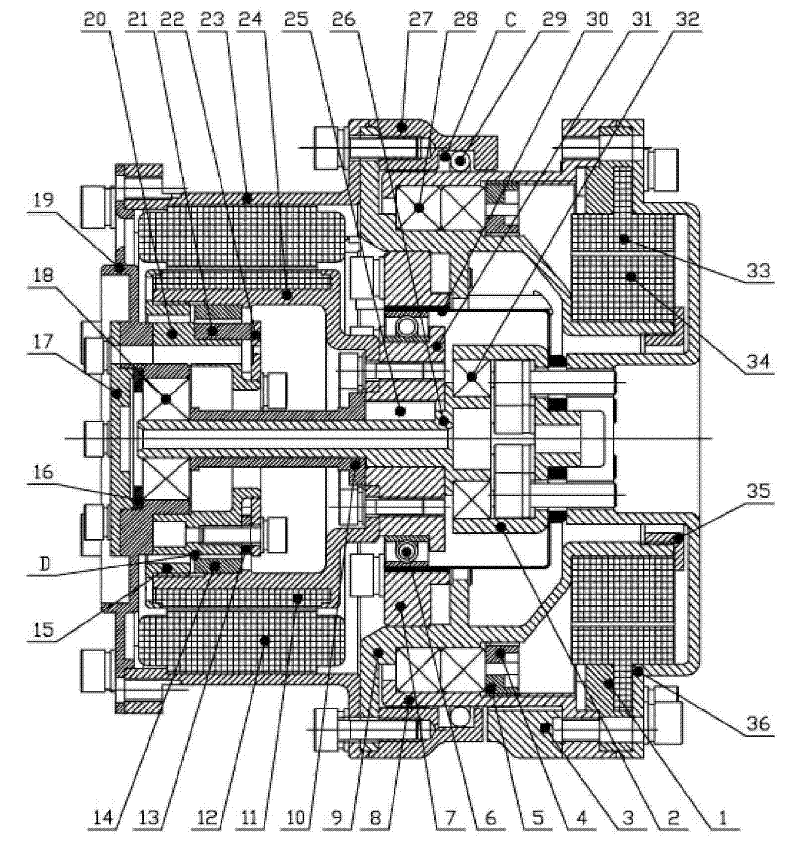

[0007] Specific implementation mode one: combine Figure 1-Figure 20 Describe this embodiment, the mechanical arm modular joint of this embodiment includes an input device A, an output device B, a sealing device C, a motor reversing device D, a resolver bracket 1, a sleeve 10, a rotor yoke lock nut 15 and Resolver lock nut 35, the input device A includes a DC brushless motor and a casing 23, the DC brushless motor is installed in the casing 23, the output device B includes the first radial bearing outer seat 2, the joint limit Block 3, inner ring baffle 4, outer ring baffle 5, angular contact bearing outer seat 8, angular contact bearing inner seat 9, gland 17, second radial bearing 18, support seat 19, input shaft 26, back to back Duplex angular contact bearing 28, input interface 31, first radial bearing 32, output flange 36, resolver and harmonic reducer; the sealing device C includes a sealing device flange 27 and an O-ring 29; The small-diameter end of the rotor yoke 24 ...

specific Embodiment approach 2

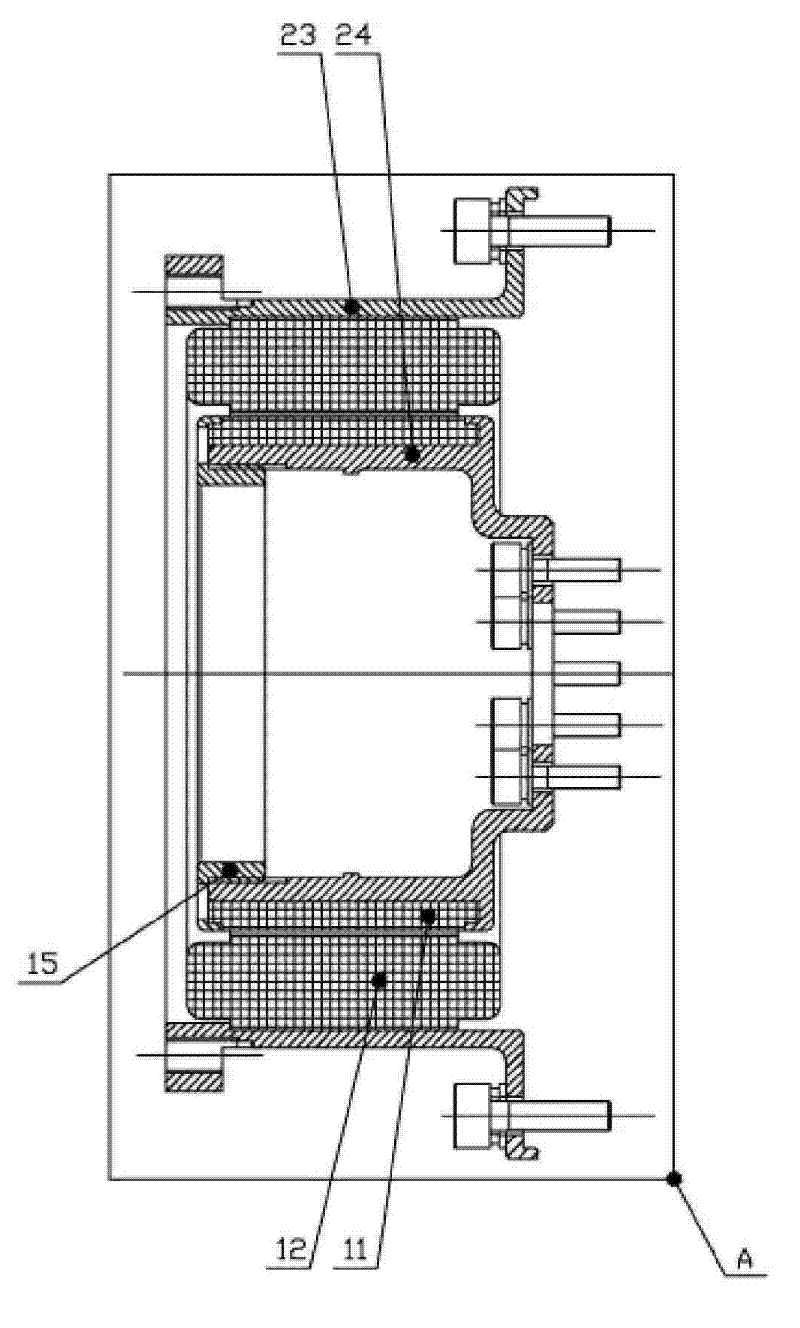

[0009] Specific implementation mode two: combination figure 2 and image 3 Describe this embodiment, the DC brushless motor of this embodiment comprises rotor 11, stator 12 and rotor yoke 24, the stator 12 of described brushless motor and the rotor 11 of brushless motor are provided with gap, the rotor of described brushless motor The yoke 24 is arranged in the stator 12 of the brushless motor, and the inner diameter of the rotor yoke 24 of the brushless motor is 28 mm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 2 , Figure 4 and Figure 5 Describe this embodiment. The harmonic reducer of this embodiment includes a flex spline 30, a rigid spline 7 and a wave generator 6. The rigid spline 7 is set on the flex spline 30, and the wave generator 6 is mounted on the flex spline 30. Inside, the outer diameter of the flexible spline 30 is 26mm, and the outer diameter of the rigid spline is 40mm. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com