Paving machine for flat surface oriented structure shaving boards

A particle board and paving machine technology, applied in flat products, household components, household appliances, etc., to achieve the effect of scientific and reasonable design, compact structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

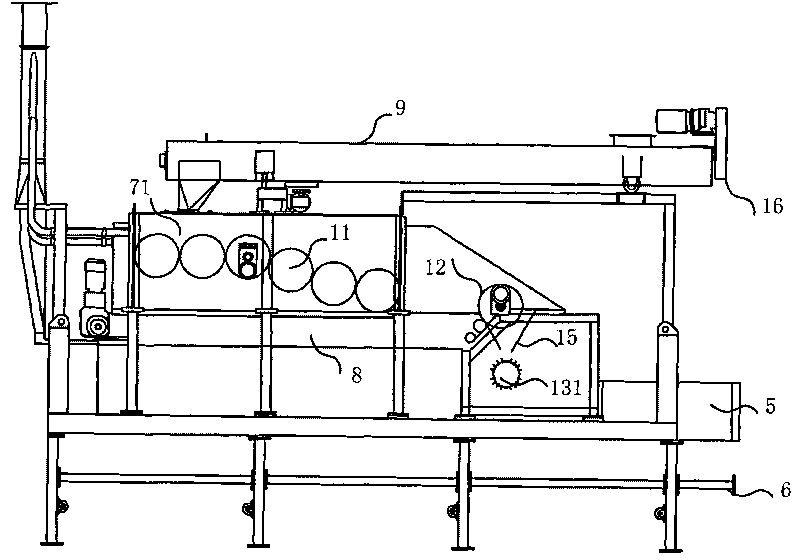

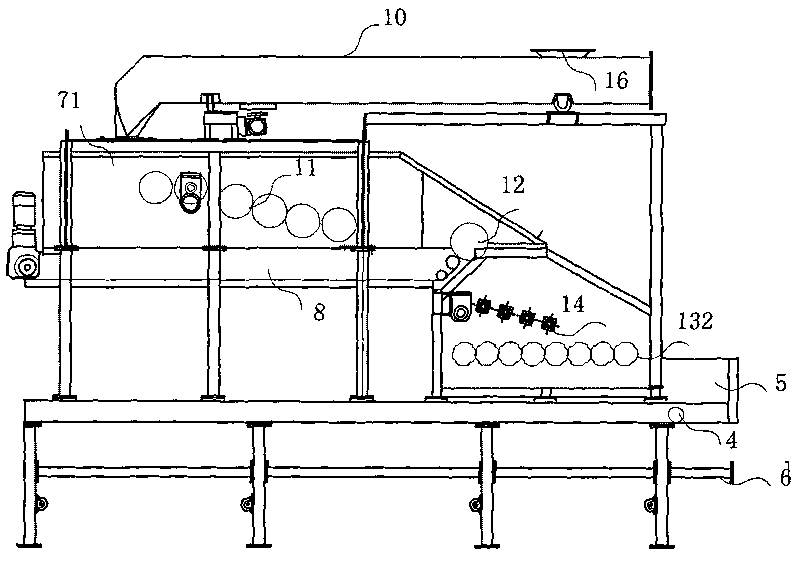

[0031] The utility model relates to a paving machine for a flat surface oriented strand board, which is one of the main equipments in the slab forming section of an oriented strand board production line. It evenly sprinkles the glued shaving wood chips or bamboo chips supplied by the previous process into the metering bin through the swing conveyor. After metering, it is loosened by a loose material rake, and evenly falls on the paving roller, and then paved on the belt through the paving roller, and the surface of each layer is smoothed by a pressing roller, and the paving forms a criss-cross slab. , and then supplied to the pre-pressing machine to pre-press into a slab with a certain strength.

[0032] The paving unit of the present invention is composed of 7 sections of paving heads, which are respectively head end surface paving head 1-1, longitudinal paving head 2-1, horizontal paving head 3-1, longitudinal paving head 2-2, The horizontal paving head 3-2, the longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com