Planet speed reduction driving mechanism

A transmission mechanism and planetary deceleration technology, applied in transmission devices, mechanical equipment, ceramic molding machines, etc., can solve the problems of rising production costs of extruders, backward configuration of reducers, and complicated structure of extruders, so as to save power consumption. , The speed ratio range is expanded, and the energy saving effect is remarkable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

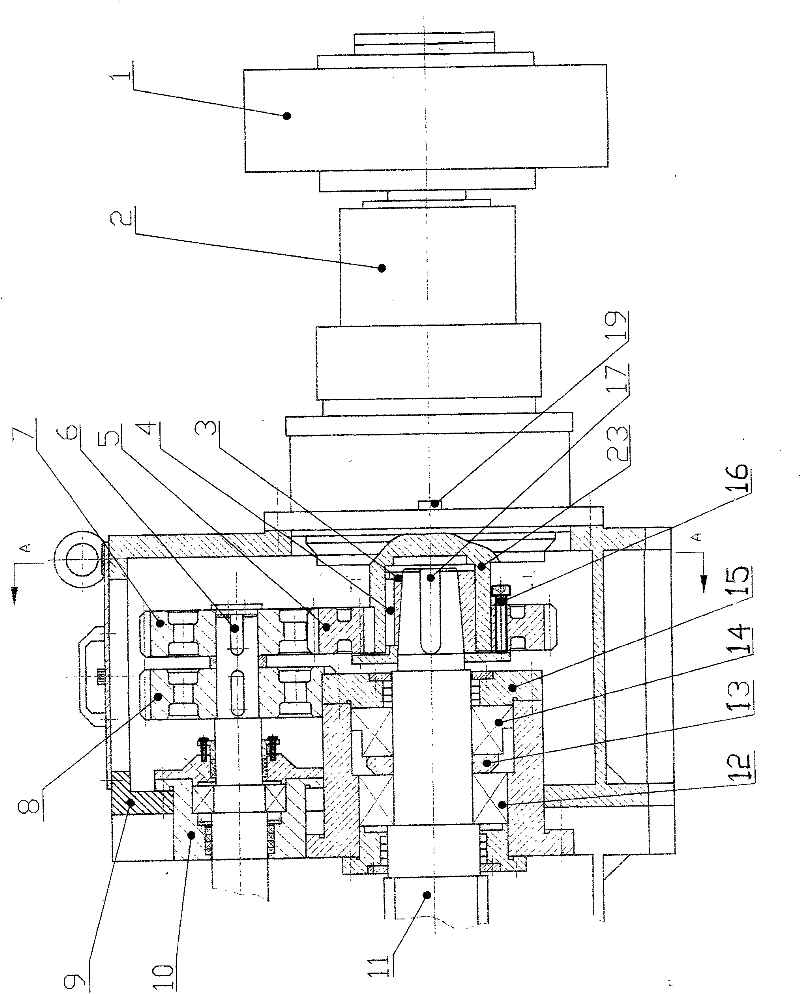

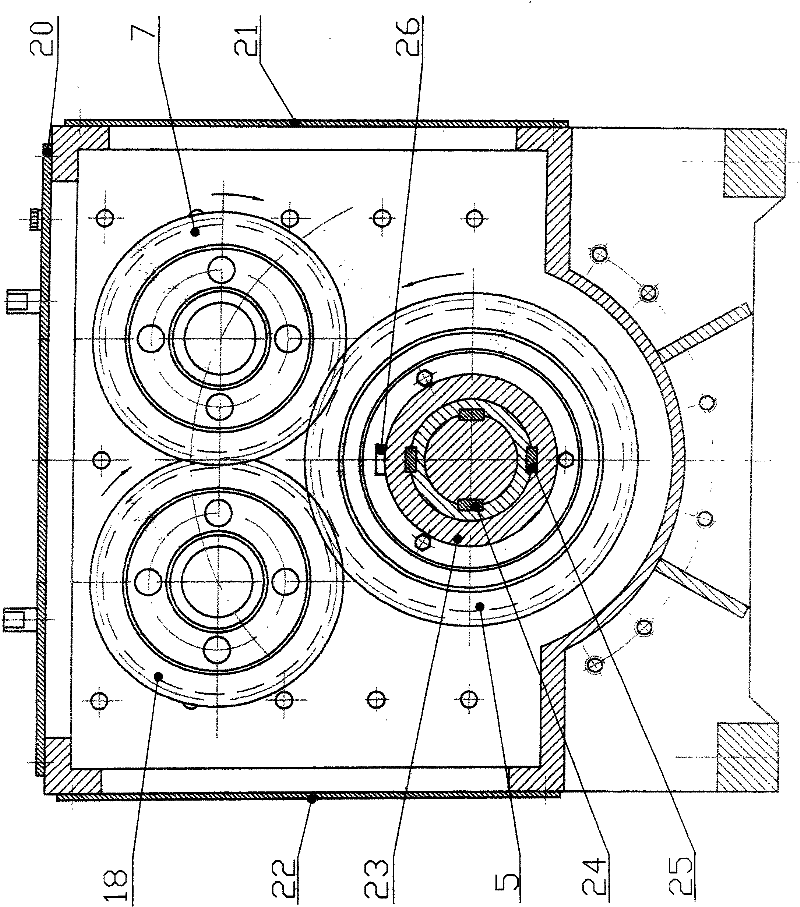

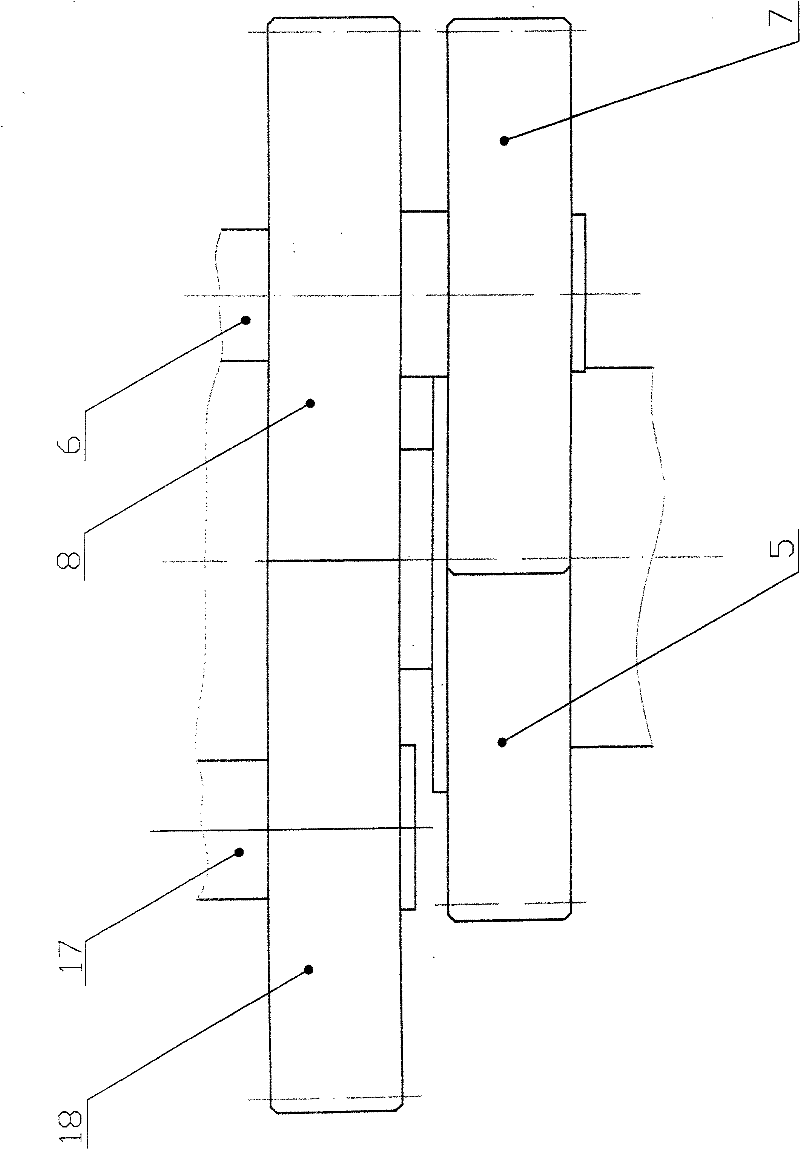

[0019] The planetary reduction transmission mechanism of the present invention mainly includes a pneumatic clutch 1, a planetary reducer 2, a transmission gearbox 9, a plurality of transmission gears, and a tensioning taper sleeve 3 and other components. The pneumatic clutch 1 is installed on the power input shaft of the planetary reducer 2, and the output shaft of the planetary reducer 2 is directly inserted into the joint hole behind the gear transmission box 9, and its fixed flange and the rear end surface of the joint hole are connected by 32 bolts 19 fixed. The driving gear 5 is installed on the output shaft of the planetary reducer 2, the driven gear 7 is installed on the upper right mud pressing shaft 6, and meshes with the driving gear, and the pair of gears 8 and the driven gear 7 are installed coaxially and on the same step, and are installed on the The pair of gears 18 on the mud pressing shaft 17 on the upper left are horizontally meshed. The extrusion shaft 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com