Novel lubricating and sealing structure for copper bush of press balance cylinder

A technology of sealing structure and balance cylinder, which is applied in the field of presses, can solve the problems of abnormal sound, short service life of balance cylinder, seizure, etc., and achieve the effect of improving lubrication condition, overall performance and adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

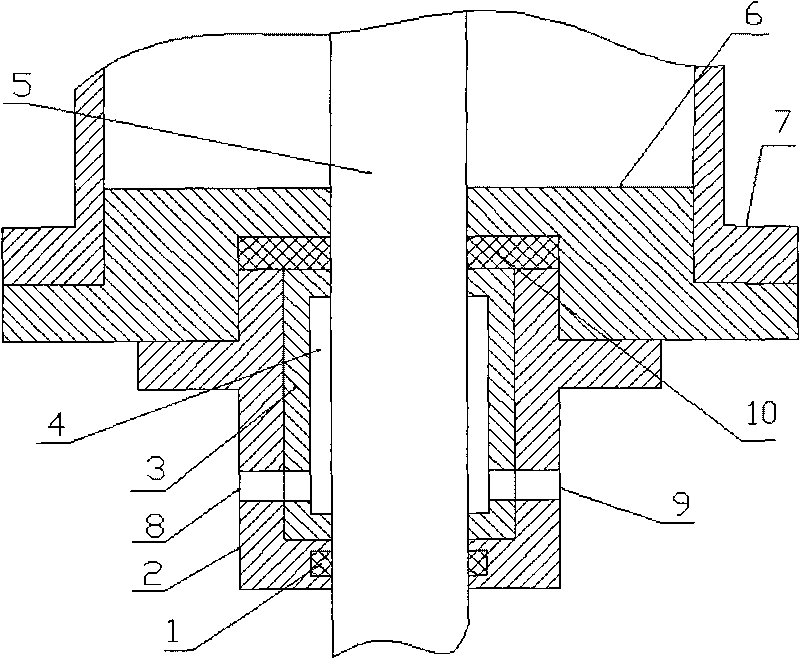

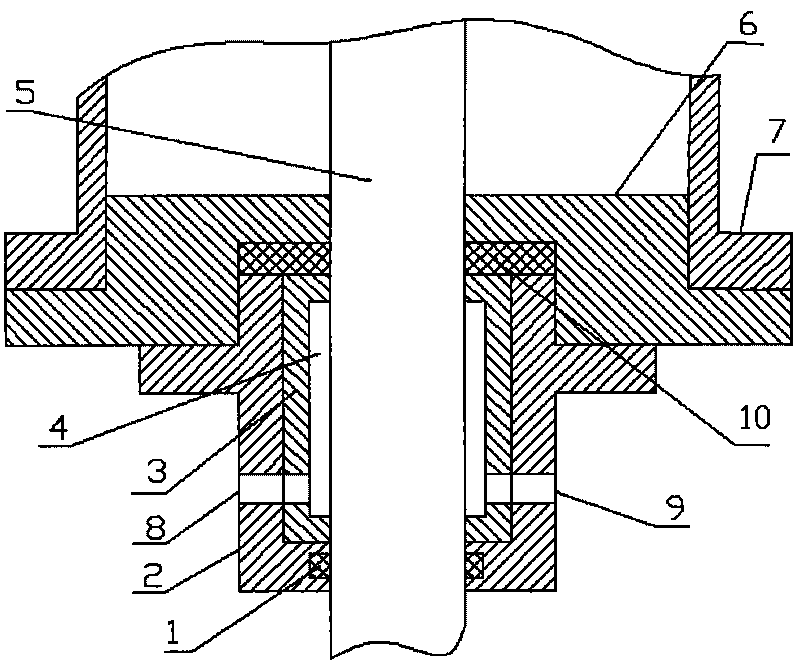

[0011] Further illustrate the present invention in conjunction with accompanying drawing and example, the present invention is made of balance cylinder (7), piston, bearing seat (2), copper sleeve (3) and piston rod (5), and bearing seat (2) is fixed on the balance On the lower cover (6) of the cylinder body (7), a corresponding step is provided at the junction of the lower cover (6) of the bearing seat (2), and the sealing ring (10) is arranged between the bearing seat (2) and the lower cover (6). ), the bearing housing (2) is fixed on the balance bar lower cover (6) through screw connection, the copper sleeve (3) is fixed in the hole of the bearing housing (2) through set screws, and the copper sleeve (3) There is a sealing groove under the inside of the lower bearing seat (2), and an oil seal (1) is built in the sealing groove, and an oil inlet hole (8) and an oil return hole (9) are set on the bearing seat (2) and the copper sleeve (3). ), lubricating oil enters the copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com