Transport system

A conveying system and conveyor belt technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve problems such as expensive and laborious costs, and achieve the effect of simplifying assembly and disassembly, flexible reconstruction, and good rotatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

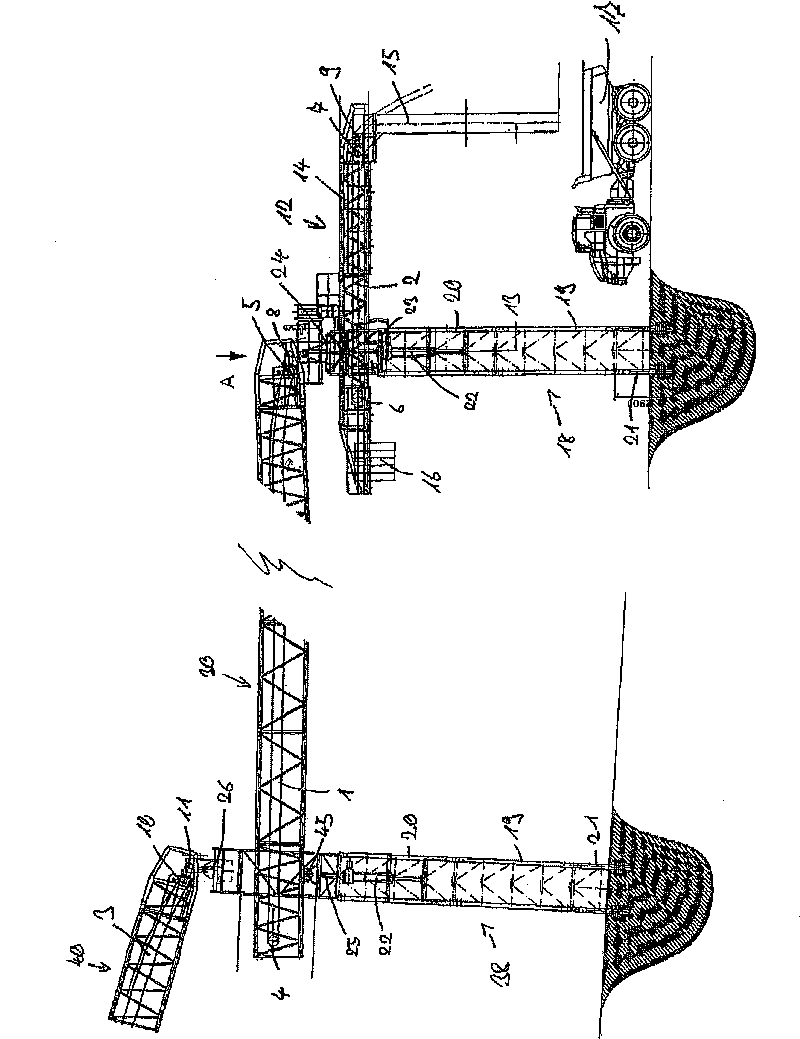

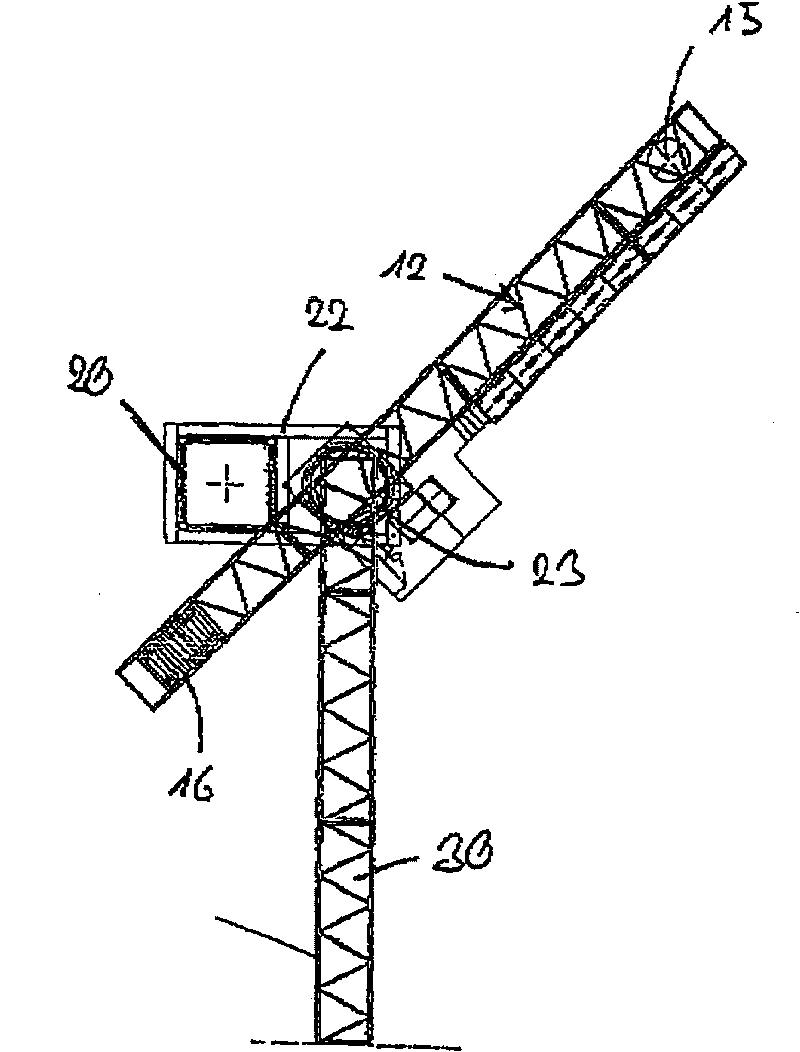

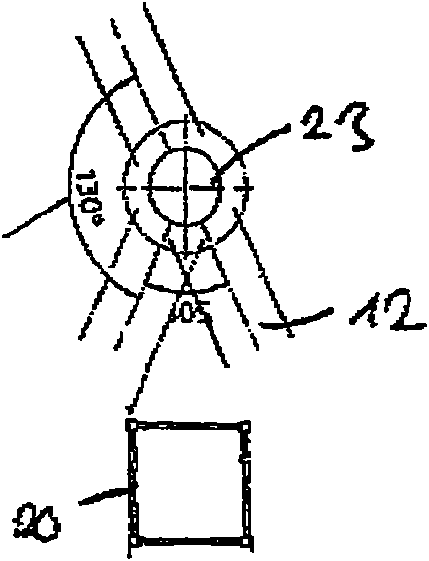

[0036] figure 1 An embodiment of a conveyor system for conveying bulk goods according to the invention is shown. In this respect, the conveying system according to the invention is used for conveying concrete, in particular liquid or semi-liquid concrete, at construction sites. In this regard, concrete is transported over long distances, for example on dam construction, to transport it from the mixing plant where the concrete is prepared to the unloading point. For this purpose, the conveying system has conveyor belts 1, 2 and 3 via which the concrete is conveyed to the unloading point. The conveyor belts 1 and 3 are arranged in belt bridges 30 and 40 and run around the rollers 4 and 5 or 10 in a continuous manner. The conveyor belts 1 and 3 are here driven by motors 8 and 11 .

[0037] Belt bridges 30 and 40 are supported by two fixed support columns 18 and 38 . In this regard, the concrete is conveyed via the belt bridge 40 onto the support column 38 where the concrete f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com