Comb teeth type hydraulic three-dimensional garage

A three-dimensional garage and comb-tooth technology, which is applied in the direction of parking buildings, building types, buildings, etc., can solve the problems of restricting large-scale hydraulic lifts, high production costs, and failure to break through the lifting height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

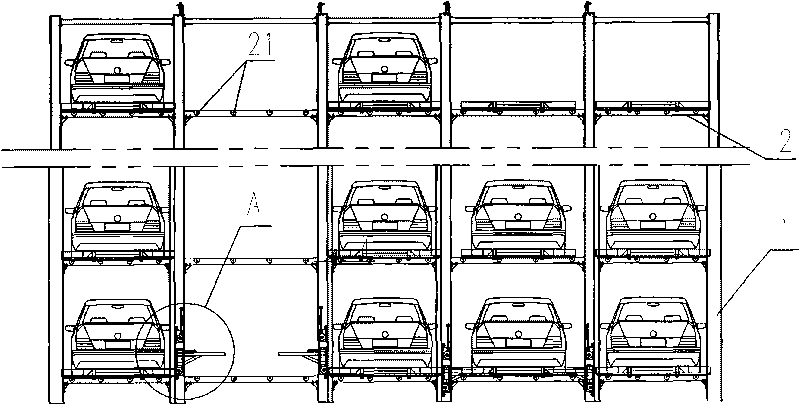

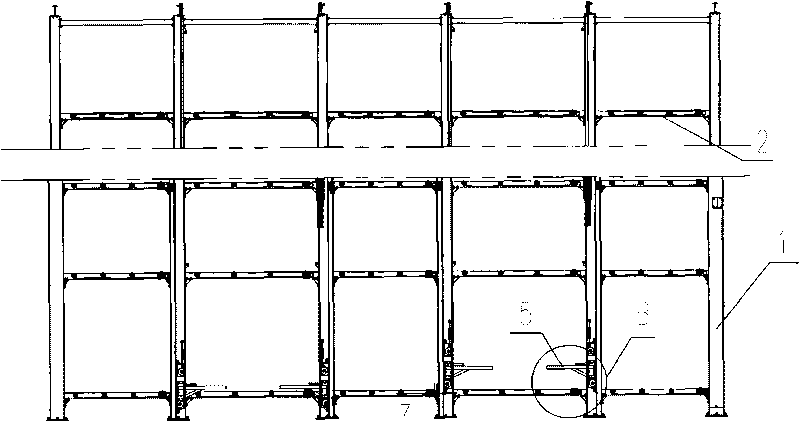

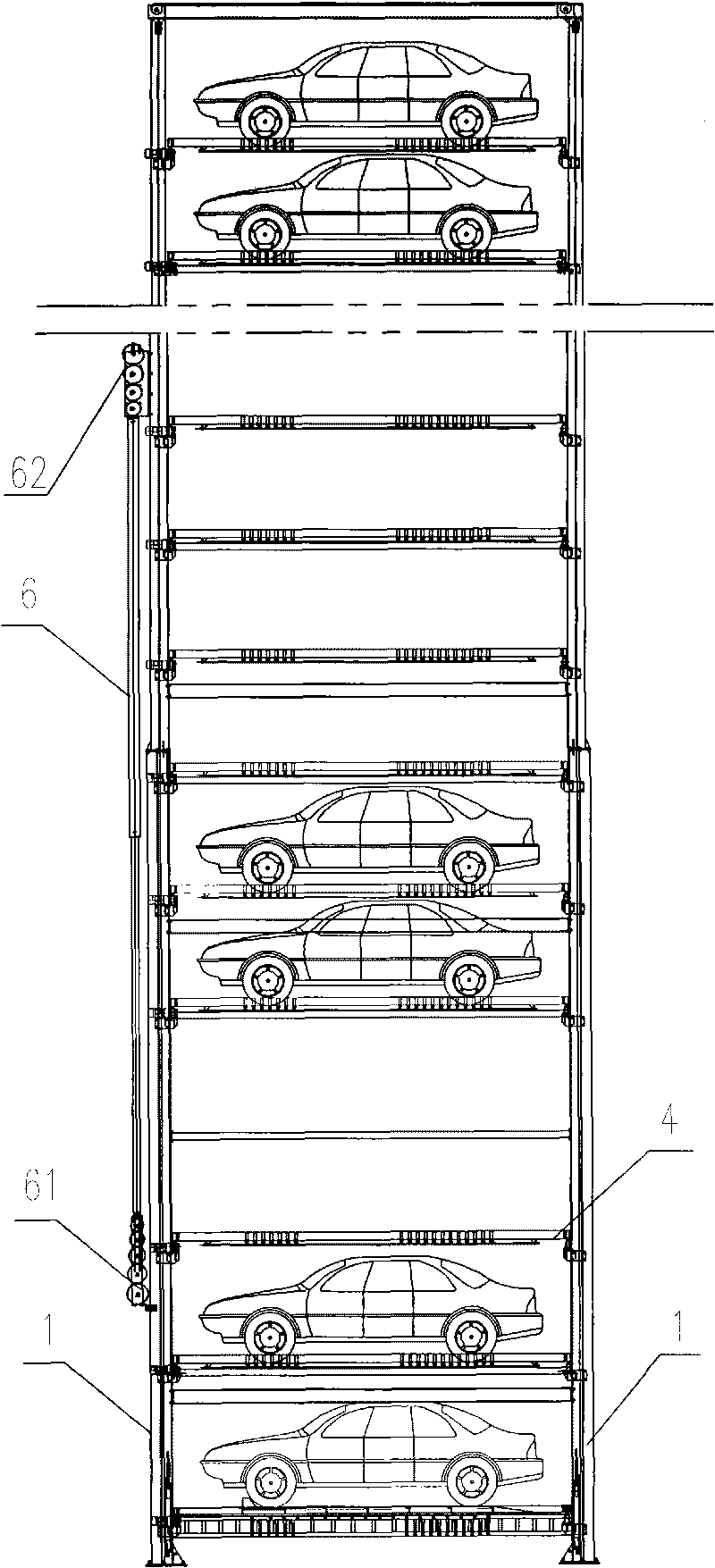

[0017] Such as figure 1 -- image 3 As shown, the comb-teeth type hydraulic three-dimensional garage of the present invention includes a column 1, a crossbeam 2, and a longitudinal beam that constitute the main frame. The column 1 adopts U-shaped channel steel or H-shaped channel steel and is vertically arranged. The groove on the column 1 Can be used as a chute. The beams 2 and the longitudinal beams are perpendicular to each other and arranged horizontally to form the garage level, and the multiple vertical columns 1 arranged in parallel divide the main frame into multiple columns, and the multiple garage levels arranged in parallel divide the main frame into multiple floors. The crossbeam 2 on the first floor is equipped with driving roller 21, and driving roller 21 is through the combination of chain, sprocket wheel, or the combination of belt, belt pulley and traversing drive motor 22 transmission connections, and traversing drive motor 22 is fixedly installed on the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com