Assembled aluminum wood energy-saving door/window

A prefabricated, aluminum-wood technology, applied in the direction of window/door frame, wing frame, wing leaf layout, etc., can solve the problems of inability to carry out standardized large-scale production, difficulty in assembling aluminum fan frame and solid wood fan frame, etc. The effect of good interior decoration effect, good sealing performance and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

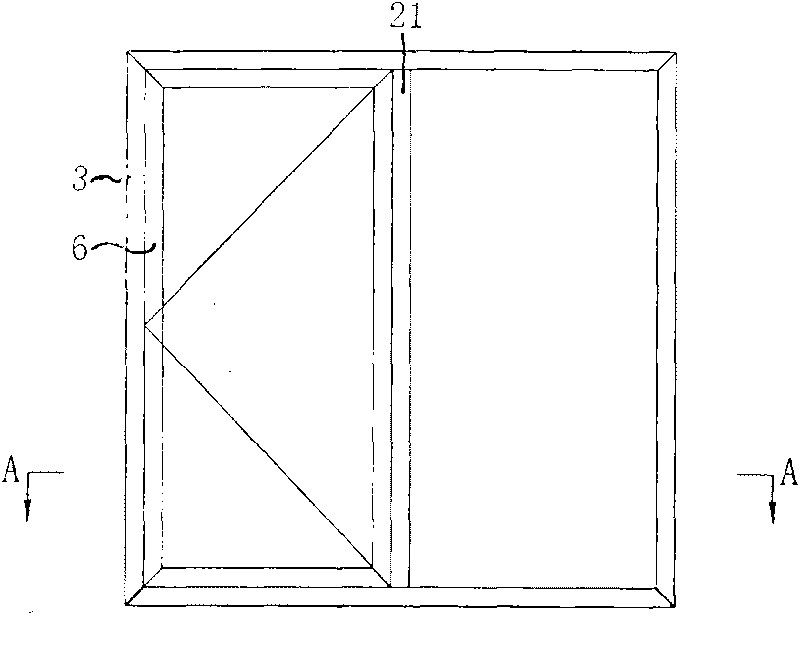

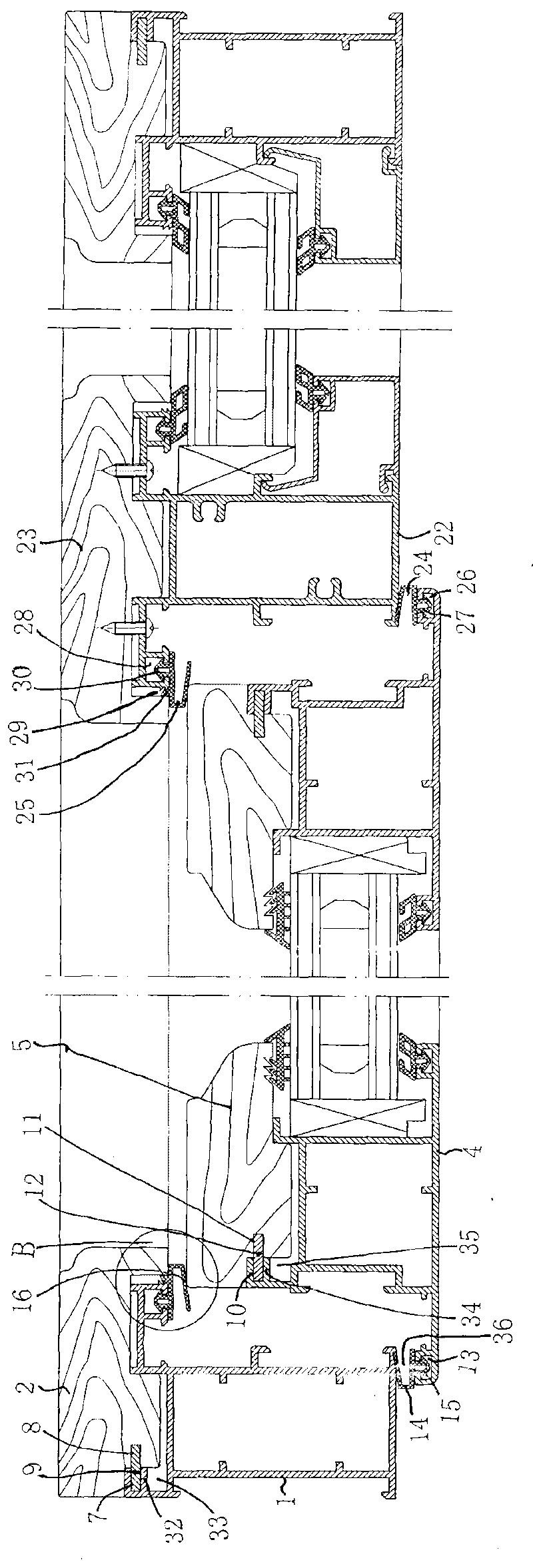

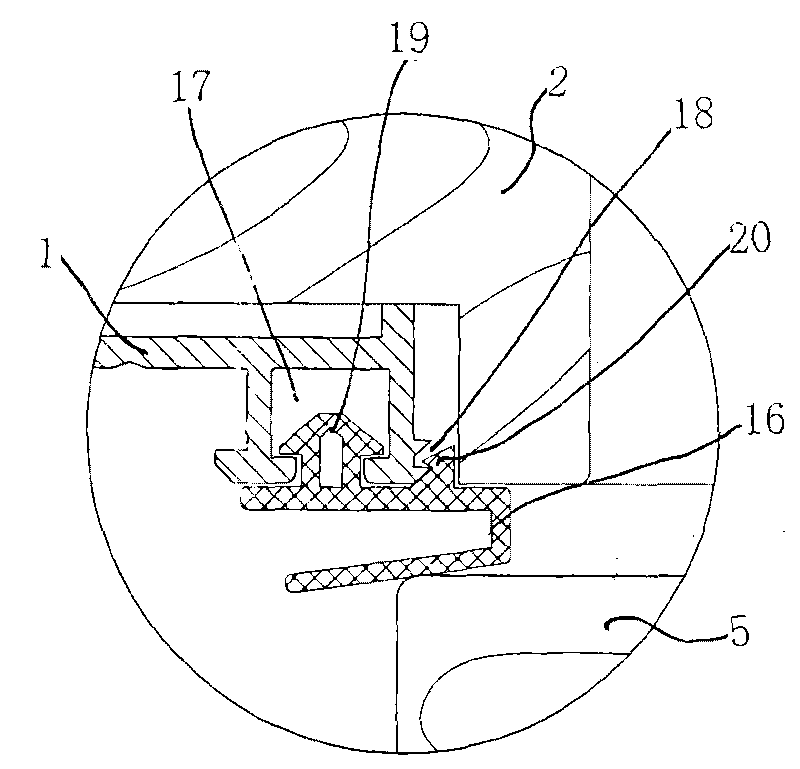

[0021] see Figure 1 ~ Figure 3 , The assembled aluminum-wood energy-saving door and window of this embodiment includes an outer frame 3 with an aluminum frame 1 and a solid wood frame 2, and a frame fan 6 with an aluminum fan frame 4 and a solid wood fan frame 5. There are draw-in grooves 7,8 respectively on the protruding portion 32 of the end of the aluminum frame and the corresponding position of the solid wood frame; Solid wood frame connection. There is a cavity 33 at the protruding part of the adjacent aluminum frame and between the aluminum frame and the solid wood frame. There are draw-in grooves 10, 11 respectively on the protruding part 37 of the end of the aluminum fan frame and the corresponding position of the solid wood fan frame. The frame is connected with the solid wood fan frame. There is a cavity 35 between the aluminum fan frame and the solid wood fan frame at the protruding part of the adjacent aluminum fan frame.

[0022] see figure 2 , image 3 T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap