Stall detection by use of pressure sensors

A pressure and stall technology, applied in the field of blade stall and wind turbine installations, can solve the problems of fluid stall, increased lift at the angle of attack, suspension of lift, etc., and achieves the effect of avoiding blade performance degradation and high lift-drag ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

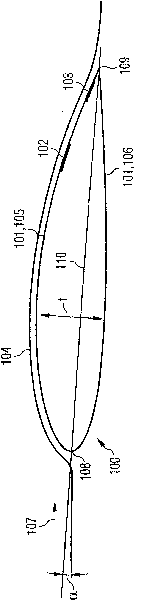

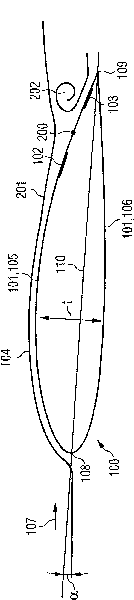

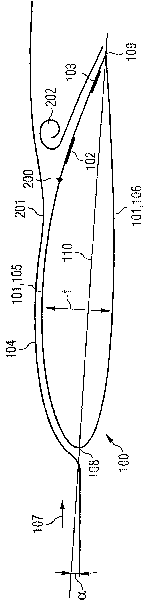

[0035] The figures shown are schematic only. It should be noted that in different drawings, the same or similar elements are marked with the same reference numerals, or the reference numerals differ from the corresponding reference numerals only in the first position.

[0036] figure 1 A blade 100 of a wind turbine 400 is shown. The blade 100 comprises a blade surface 101 and a pressure measurement device 102 providing a pressure value for stall detection. The pressure measurement device 102 is located at the blade surface 101 such that the pressure of the fluid 104 flowing along the blade surface 101 can be measured by the pressure measurement device 102 .

[0037] By measuring the pressure of the fluid 104 flowing along the blade surface 101 , a stall region of the fluid flowing along the surface or a separated flow region of the fluid 104 can be detected. Thus, a stall of the fluid 104 from the blade surface 101 can be detected. Stalling of the fluid 104 may occur due t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com