Dust removing method of surface mine dumping plough

A soil dumper and mining technology, which is applied in the field of dust removal, can solve the problems of large unloading drop, secondary pollution, and single dust removal method of the soil dumper, and achieve the effect of suppressing secondary dust and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

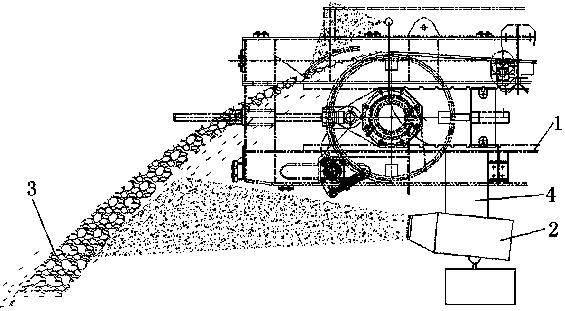

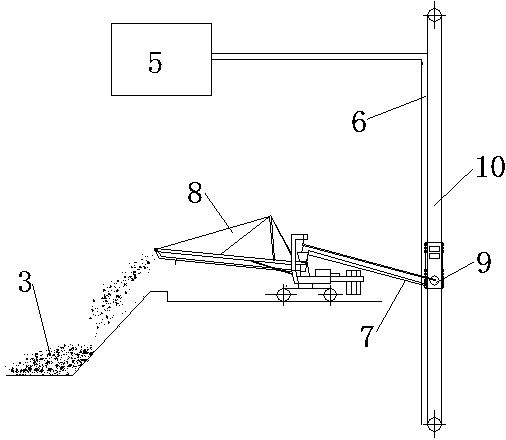

[0029] Such as Figure 1~2 As shown, the present invention adopts the dust removal equipment of a soil dumper to remove dust, and a dust removal method for a soil dumper in an open-pit mine adopts the mode of combining the spray dust removal method and the spray dust removal method. The lower part is equipped with a dust-removing air-supply sprayer 2, and the dust-removing air-supply sprayer 2 is installed at the lower part of the discharge arm 1 at a horizontal distance of 20 meters from the blanking point 3. Since the discharge arm 1 can move up and down, left and right, its load-bearing part is at a distance of 20 meters. 20 meters from the blanking point, it is suitable to install the fixed frame 4 of the dust removal air-supply sprayer; the spray dust removal method is to install the nozzle 5 on the head of the discharge arm 1, and the nozzle 5 is connected to the dust removal water pipe.

[0030] figure 1 The structure of the dust removal device of the soil dumper is sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com