High wind-speed tunnel air electric dust-collection system

A tunnel air and electrical dust collection technology, applied in the system field of air purification technology, can solve the problems of reduced dust removal efficiency, uneven electrostatic field, affecting dust removal efficiency, etc., and achieve the effect of easy installation and suppression of secondary dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

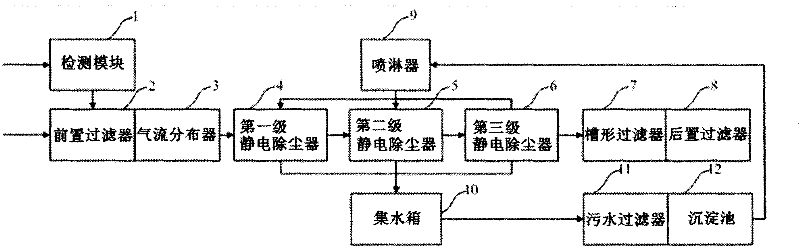

[0024] This embodiment includes: a detection module 1, a pre-filter 2, an air distributor 3, a first-stage electrostatic precipitator 4, a second-stage electrostatic precipitator 5, a third-stage electrostatic precipitator 6, a slot filter 7, Post-filter 8, sprinkler 9, water collection tank 10, sewage filter 11 and sedimentation tank 12, wherein: the input ends of detection module 1 and pre-filter 2 all receive tunnel air, the input end of airflow distributor 3 Connected to the output end of the pre-filter 2, the first-stage electrostatic precipitator 4, the second-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com