A medium and low rank coal pyrolysis gasification system and its application

A technology for pyrolysis, gasification, and low-rank coal, applied in the coal chemical industry, can solve the problems of low dust removal efficiency of the first-stage cyclone dust collector, complicated tar treatment process, blockage of pipes and equipment, etc., so as to reduce the burden of dust removal and avoid equipment Corrosion, the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

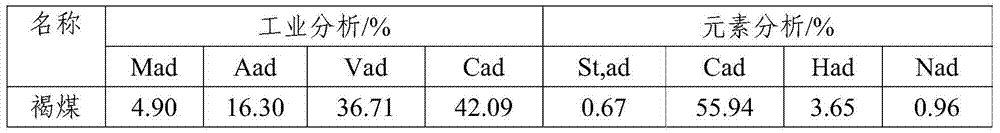

Embodiment 1

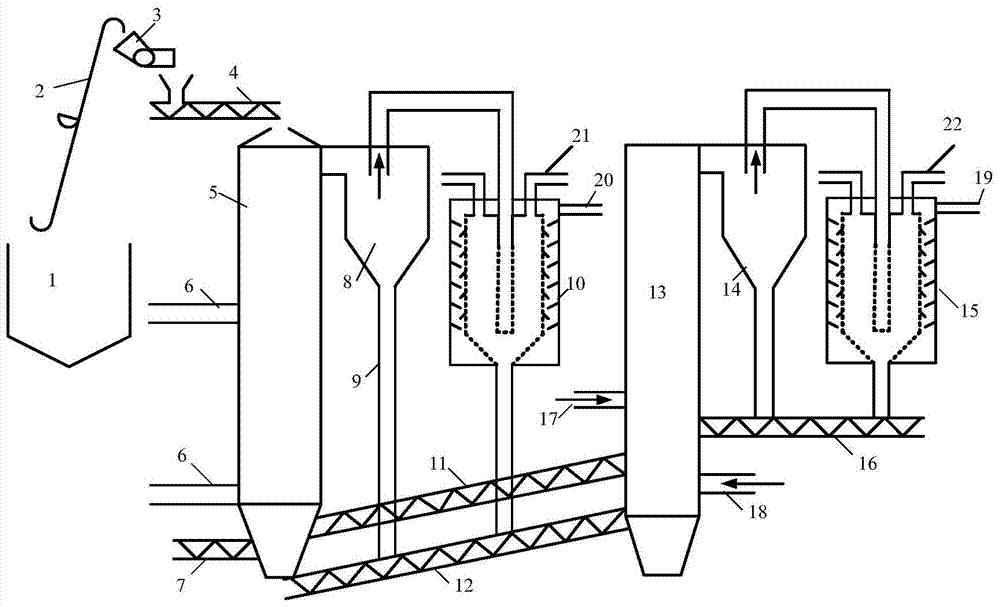

[0038] See figure 1 , medium and low-rank coal pyrolysis gasification system, including pyrolysis reactor 5, first cyclone separator 8, first cross-type particle moving bed 10, gasification reactor 13, second cyclone separator 14 and second Traversing particle moving bed 15; Raw coal is extracted from bunker 1 by bucket elevator 2, crushed by crusher 3, and transported to pyrolysis reactor 5 by feeding screw 4.

[0039] The pyrolysis reactor 5 is provided with a medium and low-rank coal inlet and a synthesis gas inlet 6. The gas discharge pipe on the upper part of the pyrolysis reactor 5 is connected to the inlet pipe of the first cyclone separator 8, and the gas outlet at the top of the first cyclone separator 8 is connected to The first cross-type particle moving bed 10, the coal pyrolysis gas is dedusted by the first cyclone separator and desulfurized by the first cross-type particle moving bed to obtain net pyrolysis gas, and the obtained net pyrolysis gas is obtained by p...

Embodiment 2

[0053] In the system of this embodiment, the pyrolysis reactor is a regenerative rotary furnace (moving bed), and a synthesis gas inlet is arranged on the pyrolysis reactor; the bottom of the pyrolysis reactor is provided with a hot semi-coke discharge spiral, and the The hot semi-coke discharge screw is connected with the semi-coke inlets on the walls of the first descending bed and the second descending bed.

[0054] Other settings of the system are the same as in Embodiment 1.

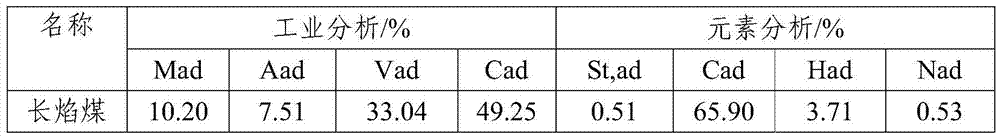

[0055] Using the system of this embodiment, the composition of long-flame coal is shown in Table 2.

[0056] Table 2: Long flame coal composition

[0057]

[0058] Coal pyrolysis gasification includes steps:

[0059] 1) Medium and low-rank coal enters pyrolysis reactor 5 after crushing, and the pyrolysis temperature is controlled at 700°C. Semi-coke and pyrolysis oil and gas are produced by pyrolysis in the pyrolysis reactor. After dedusting and desulfurization in the moving bed, ash-free and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com