Stainless steel heat exchanger

A heat exchanger, stainless steel technology, applied in the field of new heat exchangers, can solve the problems of low heat conversion rate, large heat loss, environmental pollution, etc., and achieve the effect of high heat conversion efficiency, less heat loss and high heat conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings.

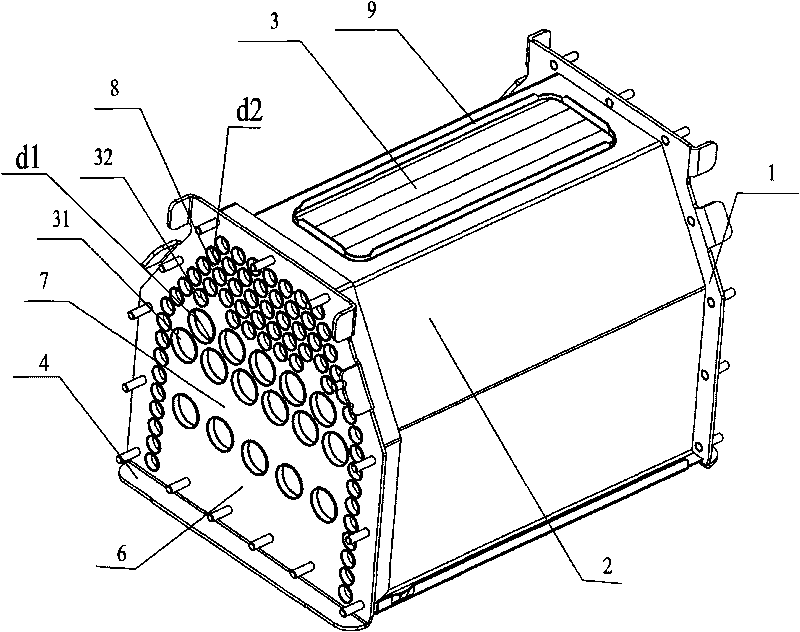

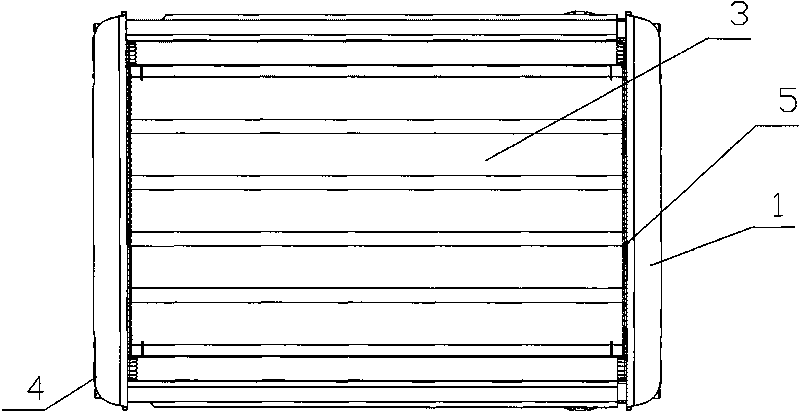

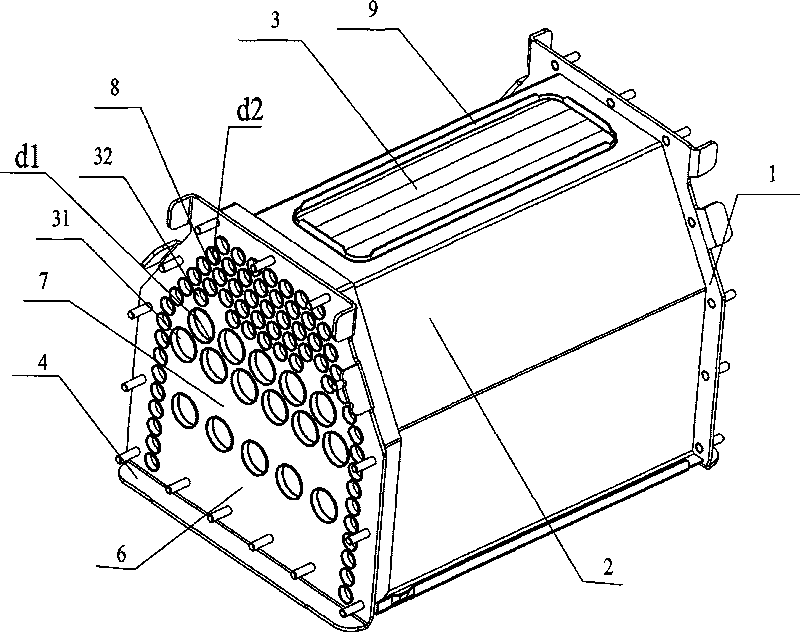

[0014] Depend on figure 1 , 2 As shown, the stainless steel heat exchanger includes a right tube plate 1, a left tube plate 4, a heat dissipation tube 3, and a housing 2, and it is characterized in that: the two ends of the housing 2 are provided with right tubes with mounting holes plate 1 and left tube plate 4; the radiating tubes 3 are arranged in the housing 2, and the two ends of the radiating tubes 3 are respectively inserted into corresponding holes of the right tube plate 1 and the left tube plate 4; the radiating tubes 3 are divided into It is the first radiating pipe 31 and the second radiating pipe 32; the inside of the housing 2 is divided into three chambers, the bottom is the combustion chamber 6, the middle is the dredging chamber 7, and the top is the tight tube chamber 8; the dredging The first radiating pipes 31 are arranged in the chamber 7; the second rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com