Method for modifying hydrophility of plasmons at surface of fluorine and silicon hard corneal contact lens

A surface plasmon and contact lens technology, applied in plasma, glasses/goggles, optics, etc., can solve the problems affecting the wearing comfort of glasses, poor hydrophilicity, and affecting deposition, etc., to achieve mass production, Increased hydrophilicity and reduced deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] §1, including the following steps: (1) flush the plasma processing system several times with Ar gas; (2) put the fluorosilicon contact lens into the system, and start vacuuming; (3) after the system vacuum reaches below 5Pa, pass Gas flow controller into the atmosphere, such as Ar, O 2 or N 2 , to increase the system pressure to the required pressure and stabilize it for a period of time; (4) set the required plasma treatment power; (5) set the required plasma treatment time; (6) turn on the plasma discharge power supply, and carry out surface After the processing is completed, close the intake valve, and then vacuum for a period of time.

[0031] §2. The process parameters of the plasma treatment system are as follows:

[0032] Handling Atmosphere: Ar

[0033] Plasma frequency: 40kHz

[0034] Power size: 100W

[0035] Processing time: 120s

[0036] Atmospheric pressure: 30Pa.

Embodiment 2

[0038] Concrete processing step is identical with embodiment 1 (§1), and the technological parameter of present embodiment plasma processing system is as follows:

[0039] Process atmosphere: O2

[0040] Plasma frequency: 40kHz

[0041] Power size: 100W

[0042] Processing time: 120s

[0043] Atmospheric pressure: 30Pa.

Embodiment 3

[0045] Concrete processing step is identical with embodiment 1 (§1), and the technological parameter of present embodiment plasma treatment system is as follows:

[0046] Process atmosphere: N2

[0047] Plasma frequency: 40kHz

[0048] Power size: 100W

[0049] Processing time: 120s

[0050] Atmospheric pressure: 30Pa.

[0051] Measure the contact angle of the surface hydrophilic fluorosilicon contact lens surface that each above-mentioned implementation example makes as shown in Table 1:

[0052] Table I

[0053]

Example 1

Example 2

Example 3

untreated sample

Surface contact angle (°)

32

41

40

107

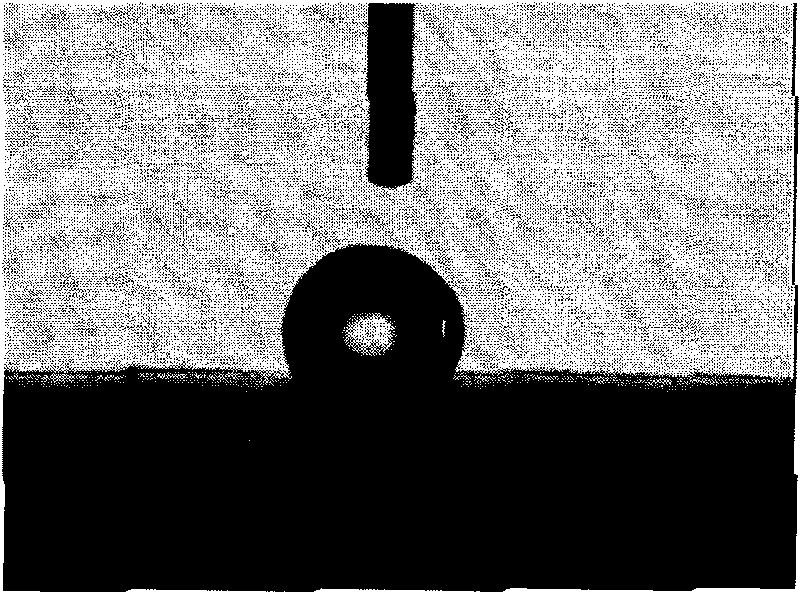

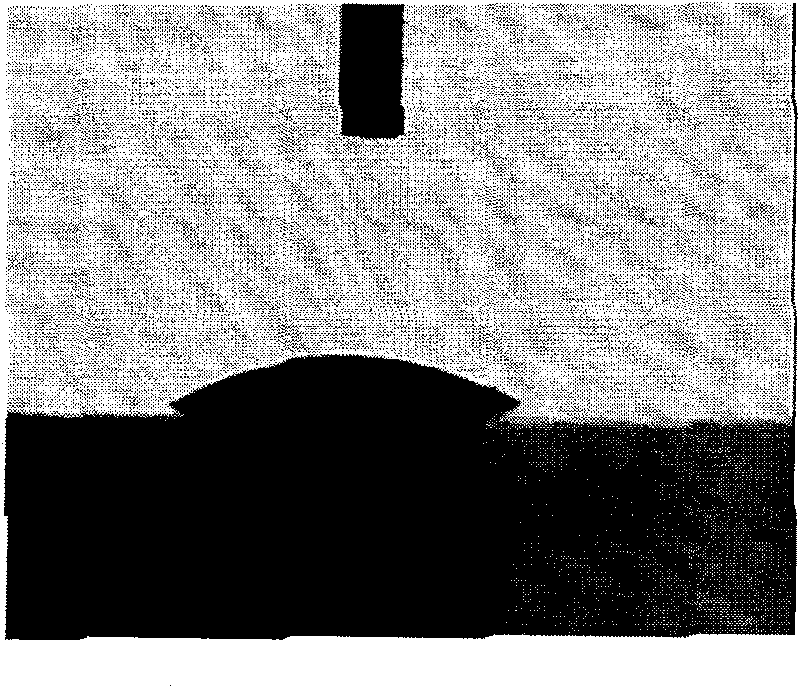

[0054] Through Table 1 and the attached figure 1 and attached figure 2It can be clearly found that the contact angle of the surface of the fluorosilicon hard contact lens treated by the process of the present invention is obviously improved.

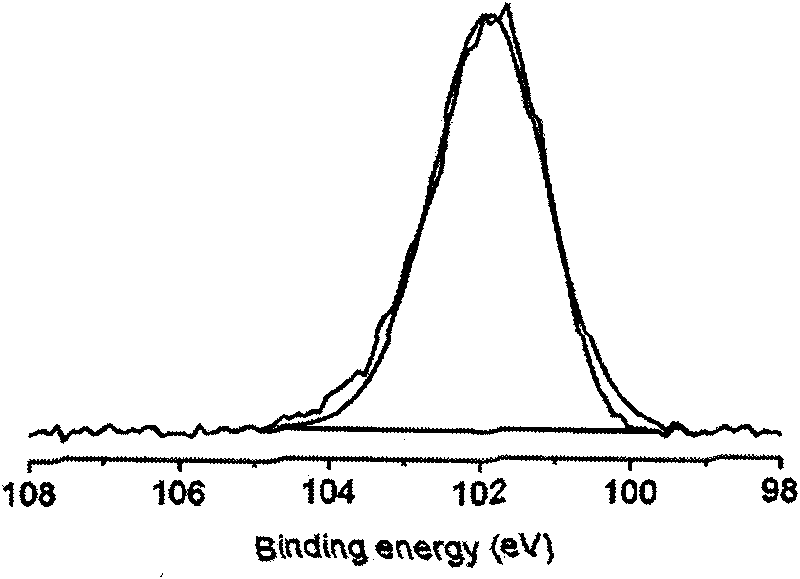

[0055] From attached image 3 And attached Figure 4 The Si2p XPS tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com