Mask cleaning device

A cleaning device and mask technology, which is applied in the mask cleaning device and its cleaning field, can solve problems such as protective film rupture, achieve the effect of avoiding rupture and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to have a more complete and clear disclosure of the technical content used in the present invention, the purpose of the invention and the effects achieved, it will be described in detail below, and please refer to the accompanying drawings and figure numbers:

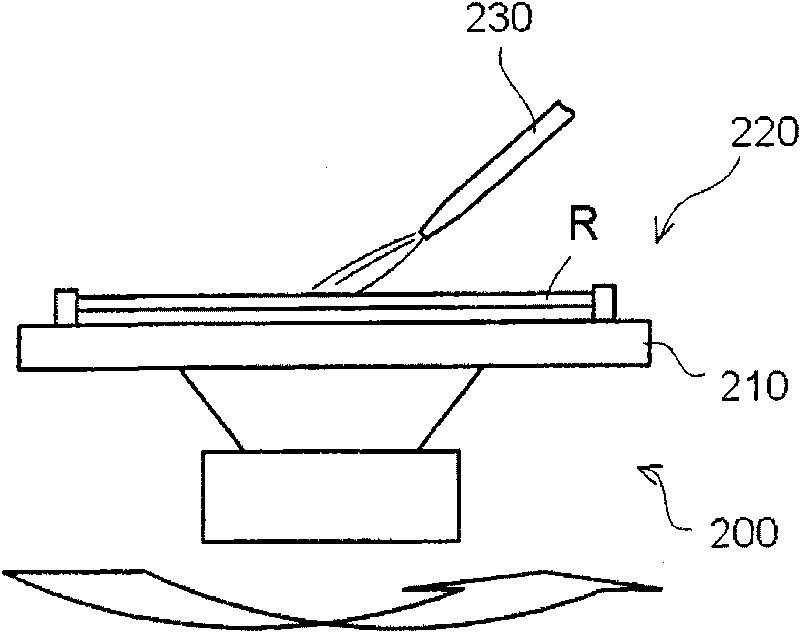

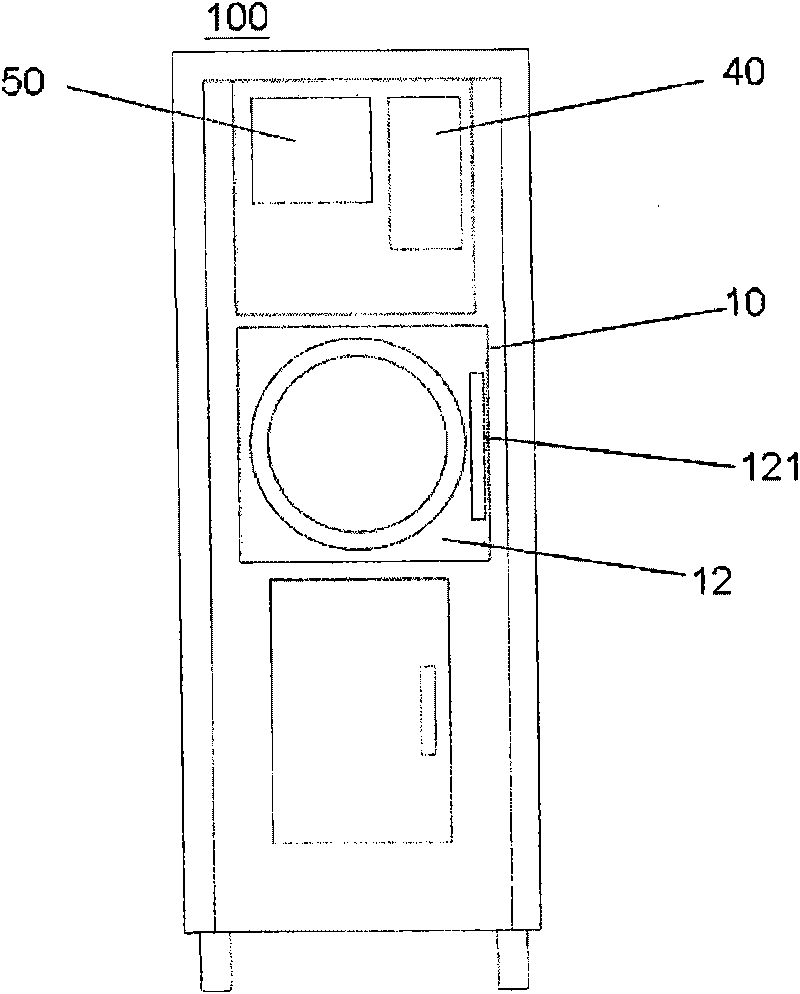

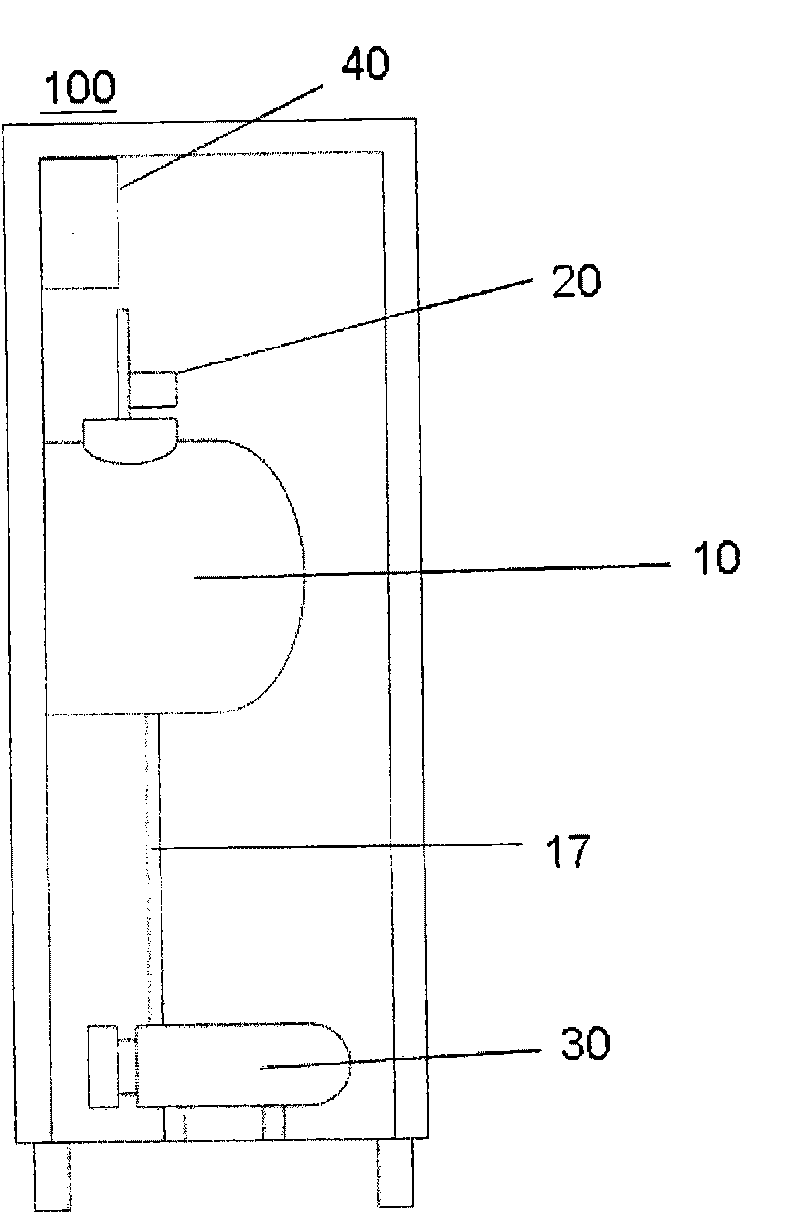

[0042] First, see Figure 2A and Figure 2B Shown is a front view and a side perspective view of a mask cleaning device of the present invention. and Figure 3A and Figure 3B , is a schematic front view and a schematic side view of the cavity of the above-mentioned mask cleaning device. The mask cleaning device 100 of the present invention includes a cavity 10, a photoelectric element 20, a pump system 30, and a controller 40, wherein the cavity 10 has an opening 11 and a cavity that can be sealed with the opening 11 The door 12 has a handle 121 on the chamber door 12 to facilitate the opening of the chamber door 12 . And inside the cavity 10 is a closed chamber 13, this closed chamber 13 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com