Wafer detection device

A detection device and chip technology, which is applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problems of long scanning time for the cassette and affect the production capacity of the equipment, and achieve the effect of smooth lifting, increasing equipment production capacity, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

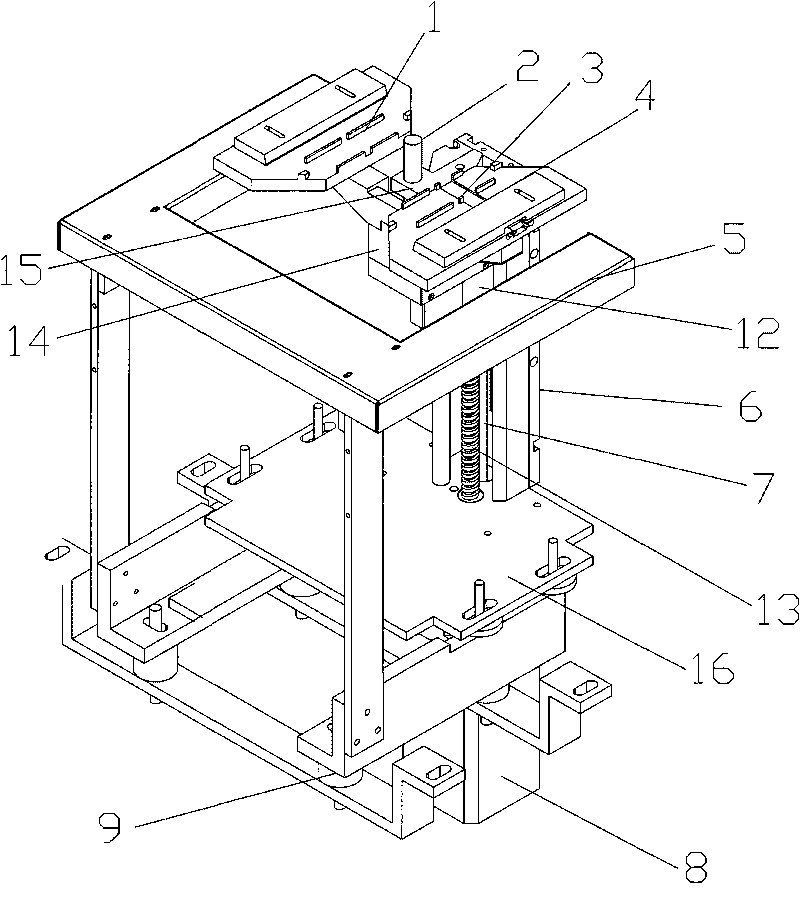

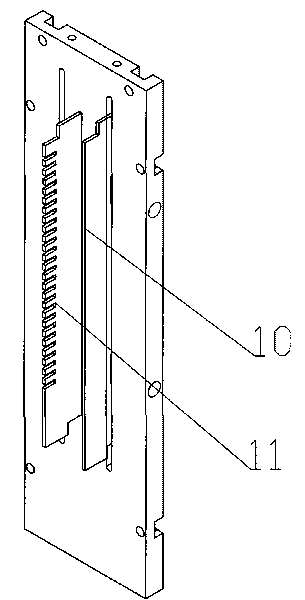

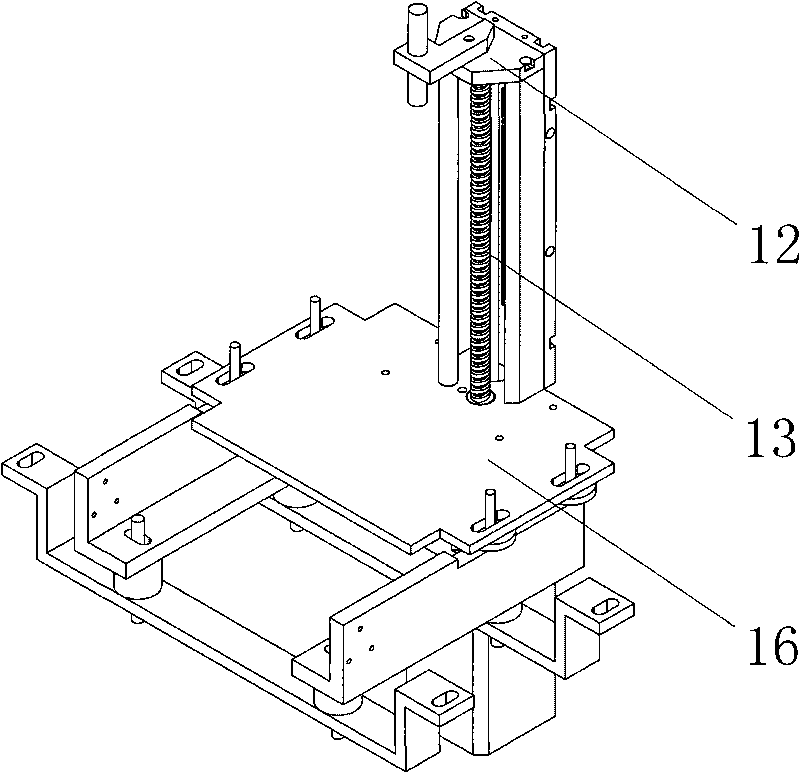

[0022] Such as Figure 1-Figure 2 As shown, the wafer detection device of the present invention mainly includes a wafer carrier, a proximity switch 2, a pressure switch 3, a support 5, a code disc device 6, a screw drive device 7, a motor 8, and a buffer pad 9, and the wafer carrier is a wafer carrier I 1. The chip holder II 4 is relatively arranged on the base 14. The bottom of the base 14 is provided with a screw drive 7. The screw drive 7 is formed by a supporting ball screw 13 and a nut 12. The base 14 and the screw The nut 12 of the transmission device 7 is connected, the screw seat 15 on the top of the ball screw 13 is equipped with a proximity switch 2, the proximity switch 2 is located between the film holder I1 and the film holder II4, and the motor 8 is driven by the transmission shaft and the lead screw. The ball screw 13 of the device 7 is connected. Lead screw transmission device 7 can be installed on the base plate 16 of support 5, and buffer pad 9 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com