Battery disposal device and method

A battery processing and battery technology, applied in the direction of battery circuit devices, circuit devices, battery recycling, etc., can solve the problems that the battery polarization cannot be effectively eliminated, the efficiency and effect are not very high, shorten the time, realize real-time monitoring, and ensure The effect of efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

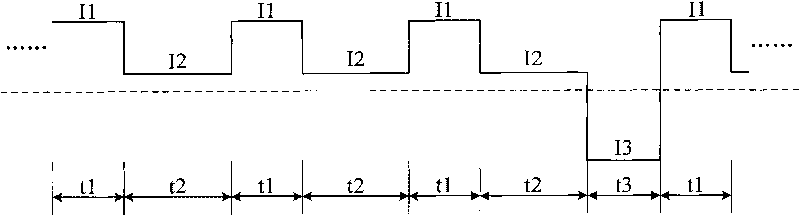

[0030] In the embodiment of the present invention, a non-intermittent direct current is applied to the battery to perform desulfurization repair on the battery, thereby shortening the desulfurization repair time of the battery, thereby improving the battery repair efficiency.

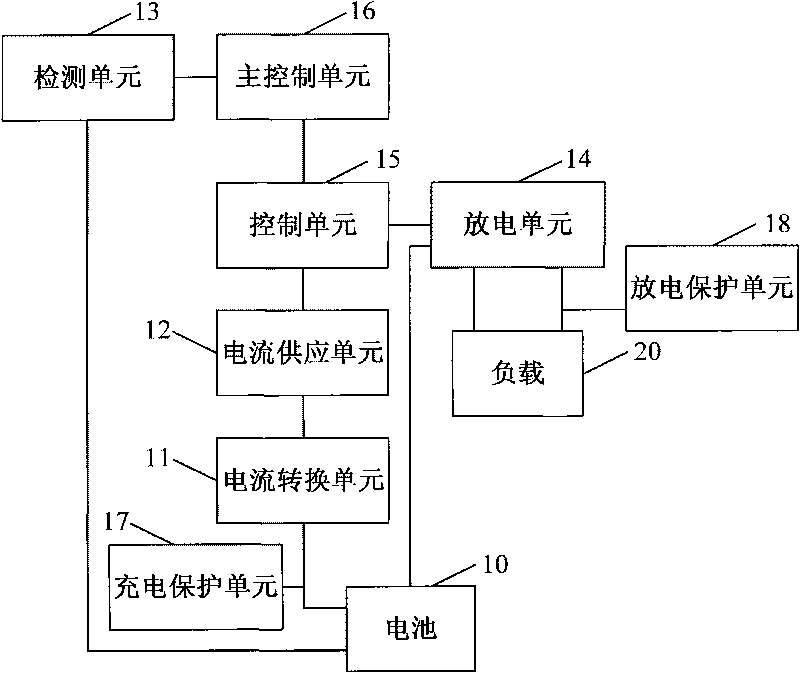

[0031] An embodiment of the present invention provides a battery processing device, including: a current conversion unit, which generates a direct current with variable current parameters, and the current parameter includes a current level; a current supply unit, which controls the current conversion unit to alternately provide a current level that is not 0 of the first current and the second current to the battery.

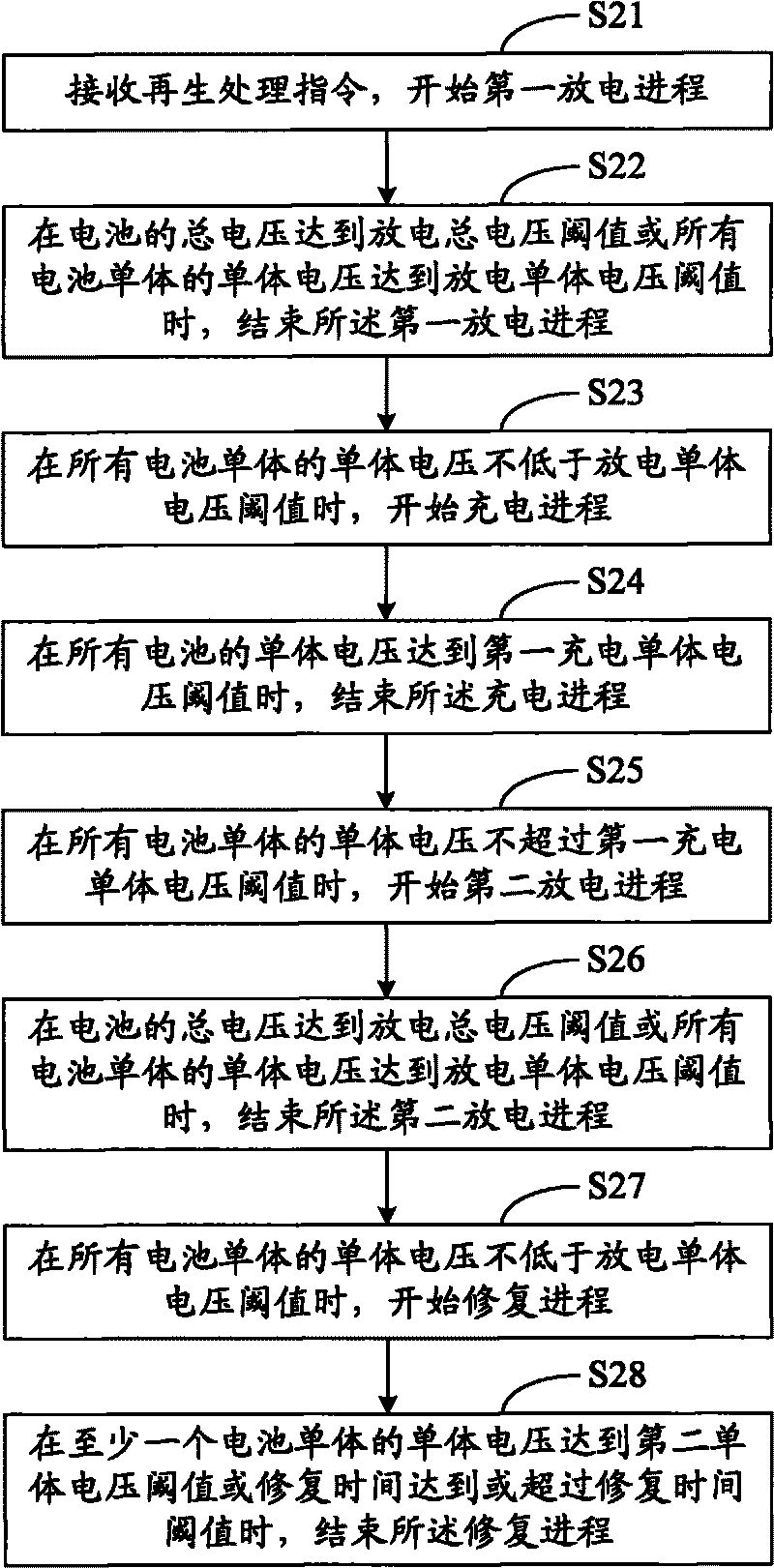

[0032] Optionally, the battery processing device further includes a discharge unit, and after the current supply unit controls the current conversion unit to supply a predetermined number of first currents and second currents to the battery, the discharge unit controls the battery to use a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com