Producing method of boiled chicken

A production method and the technology of cooking chicken, which are applied in food preparation, application, food science, etc., can solve the problems of too old, poor taste, and inability to be shipped to other places for sale, so as to ensure food safety and taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

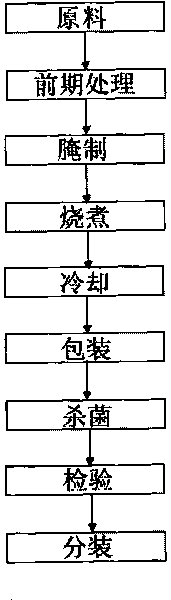

[0025] As shown in Figure 1, the specific production method is as follows,

[0026] (1) Select live chickens with a weight of 3-4 catties for pre-treatment, namely: slaughtering-depilling-evisceration-cleaning-low-temperature deacidification and sterilization;

[0027] (2) marinate the pre-treated chicken with 2% salt for 8 hours;

[0028] (3) Put the marinated chicken into the soup and cook it, then stew it on low heat for 35 minutes after boiling;

[0029] The configuration of the soup is as follows

[0030] For 100 chickens, 1.5KG / piece, the ingredients are as follows:

[0031] Fragrant leaves: 10g; Agarwood: 50g; Fennel: 80g; Cinnamon: 100g;

[0032] Cardamom: 50g; Nutmeg: 10g; Kaempfer: 10g; Clove: 30g;

[0033] Soy sauce: 200g; salt: 200g; monosodium glutamate: 50g; rice wine: 200g.

[0034] (4) Put the boiled chicken into the air-conditioning room for cooling, the temperature of the air-conditioning room is controlled at 10°C, and the cooling time is 24 hours;

[...

Embodiment 2

[0041] Other steps are equal to embodiment 1,

[0042] Pickling time is: 10 hours in the step (2);

[0043] In the step (3), the soup ingredient ratio is as follows:

[0044] Based on 100 chickens, 1.5KG / piece, the ingredients are as follows:

[0045] Fragrant leaves: 80g; Agarwood: 80g; Fennel: 100g; Cinnamon: 150g;

[0046] Cardamom: 150g; Nutmeg: 50g; Kaempfer: 150g; Clove: 200g;

[0047] Soy sauce: 800g; salt: 400g; monosodium glutamate: 100g; rice wine: 300g.

[0048] The fried chicken made by the above method is suitable for customers with strong taste.

Embodiment 3

[0050] Other steps are equal to embodiment 1,

[0051] Pickling time in step (2): 9 hours;

[0052] In the step (3), the soup ingredient ratio is as follows:

[0053] Based on 100 chickens, 1.5KG / piece, the ingredients are as follows:

[0054] Fragrant leaves: 40g; Agarwood: 30g; Fennel: 85g; Cinnamon: 80g;

[0055] Cardamom: 80g; Nut: 30g; Kaempfer: 100g; Clove: 20g;

[0056] Soy sauce: 500g; Salt: 300g; Monosodium glutamate: 80g; Rice wine: 300g.

[0057] The fried chicken made by the above method is suitable for customers with moderate taste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com