Technique for preparing almond peptide sports beverage and separating almond oil by enzyme process

A technology for sports drinks and bitter almonds, applied in food preparation, edible oil/fat, food science and other directions, can solve the problems of poor product palatability, protein destruction, and high production costs, and achieve improved quality stability, excellent nutritional quality, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

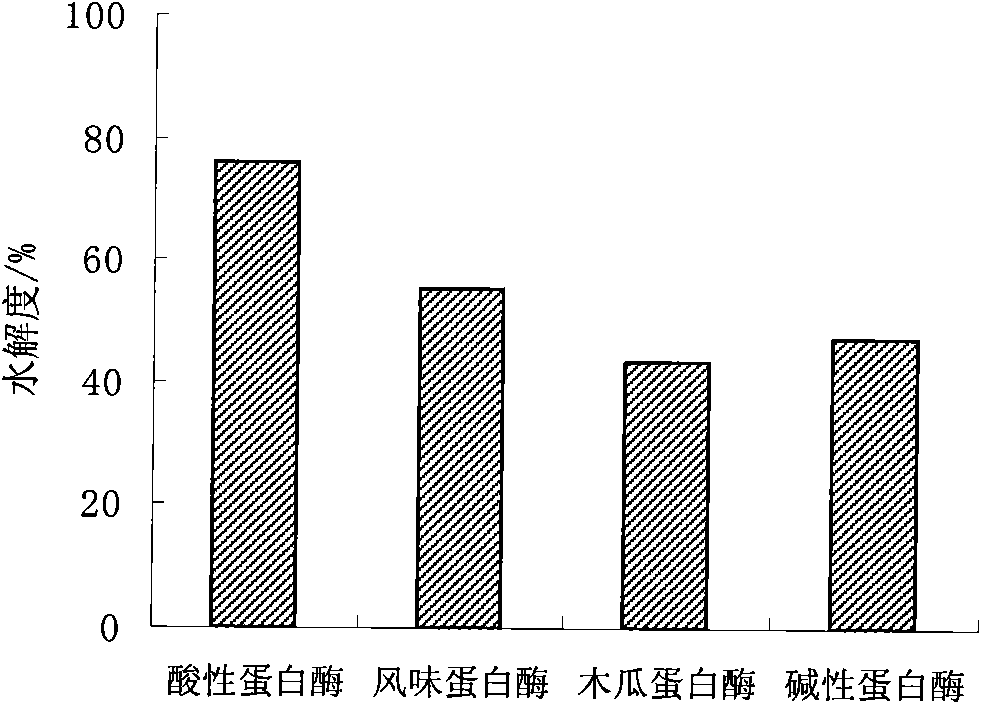

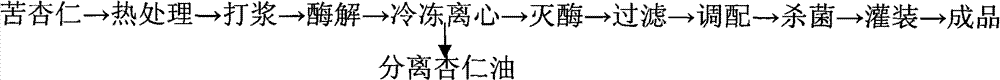

[0059] Example 1: Bitter almonds were detoxified by boiling water at 100°C for 20 minutes. The ratio of material to water is 1:10 for beating. The protein in almonds was hydrolyzed by acid protease, the enzymolysis process was 5% enzyme dosage, 50°C enzymolysis temperature, 4.5h enzymolysis time, and pH 3. The enzymatic hydrolysis solution is refrigerated and centrifuged to separate the almond peptide solution from the almond oil, the yield of almond oil is as high as 94%, and the hydrolysis degree of the almond peptide solution is 76.5%. Inactivate the enzyme with almond peptide in a boiling water bath for 10 minutes, filter the enzymolysis solution, discard the precipitate, and obtain a clear and transparent light yellow enzymolysis solution, which is the stock solution of almond peptide. Almond peptide stock solution 100mL, sucrose 20g, citric acid 2.2mg and β-cyclodextrin 1.5mg are blended together and stirred evenly. The prepared drink was sterilized at 100° C. for 10 m...

Embodiment 2

[0060] Example 2: Bitter almonds were detoxified by boiling water at 100°C for 20 minutes. The ratio of material to water is 1:10 for beating. The protein in almonds was hydrolyzed by acid protease, the enzymolysis process was 5% enzyme dosage, 55°C enzymolysis temperature, 4.5h enzymolysis time, and 2.5 pH. The enzymatic solution was frozen and centrifuged to separate almond peptide solution and almond oil, the yield of almond oil was 94.7%, and the hydrolysis degree of almond peptide solution was 76.3%. Inactivate the enzyme with almond peptide in a boiling water bath for 10 minutes, filter the enzymolysis solution, discard the precipitate, and obtain a clear and transparent light yellow enzymolysis solution, which is the stock solution of almond peptide. Almond peptide stock solution 100mL, sucrose 25g, citric acid 2mg and β-cyclodextrin 2mg are blended together and stirred evenly. The prepared drink was sterilized at 100° C. for 10 minutes to obtain the almond peptide sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com