Tower section of packed tower for chemical synthesis and rectification

A packed tower, chemical synthesis technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc. There are obstacles and other problems to achieve good results and reliable test data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

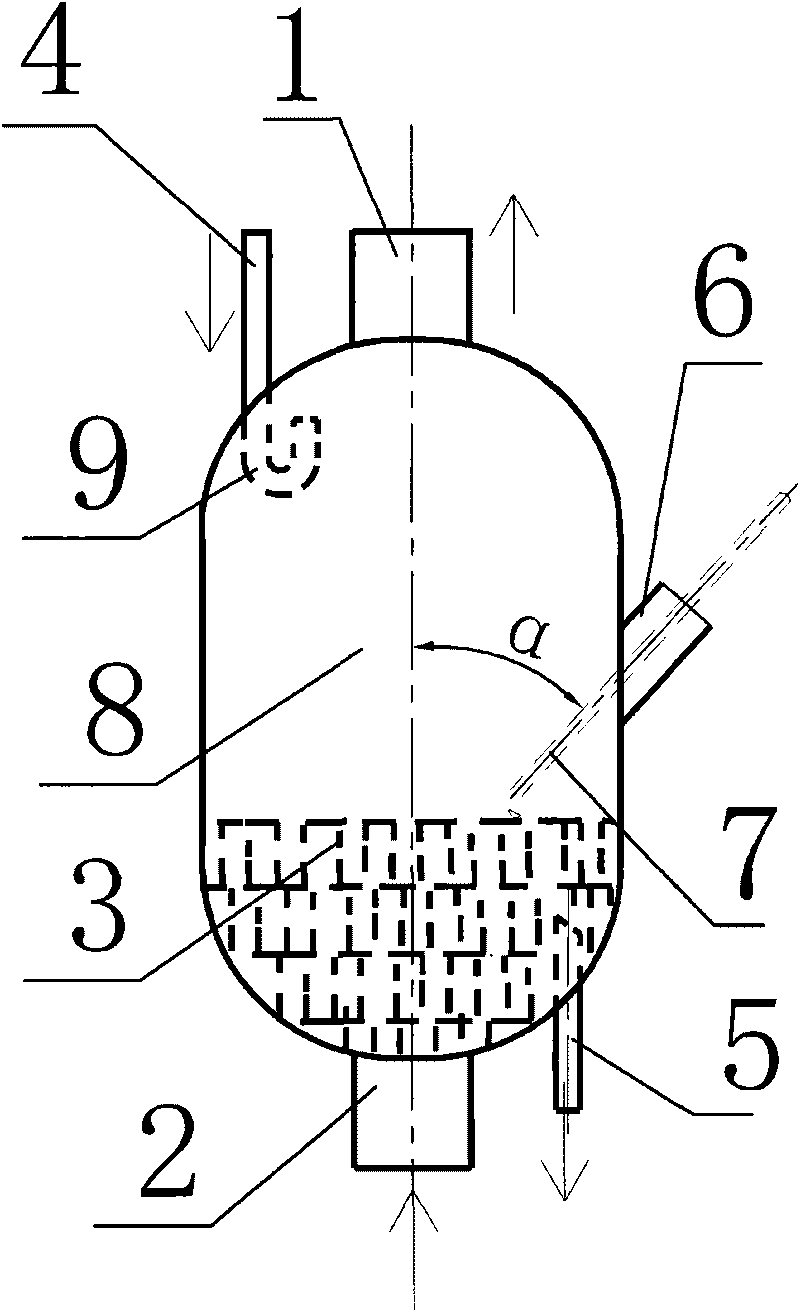

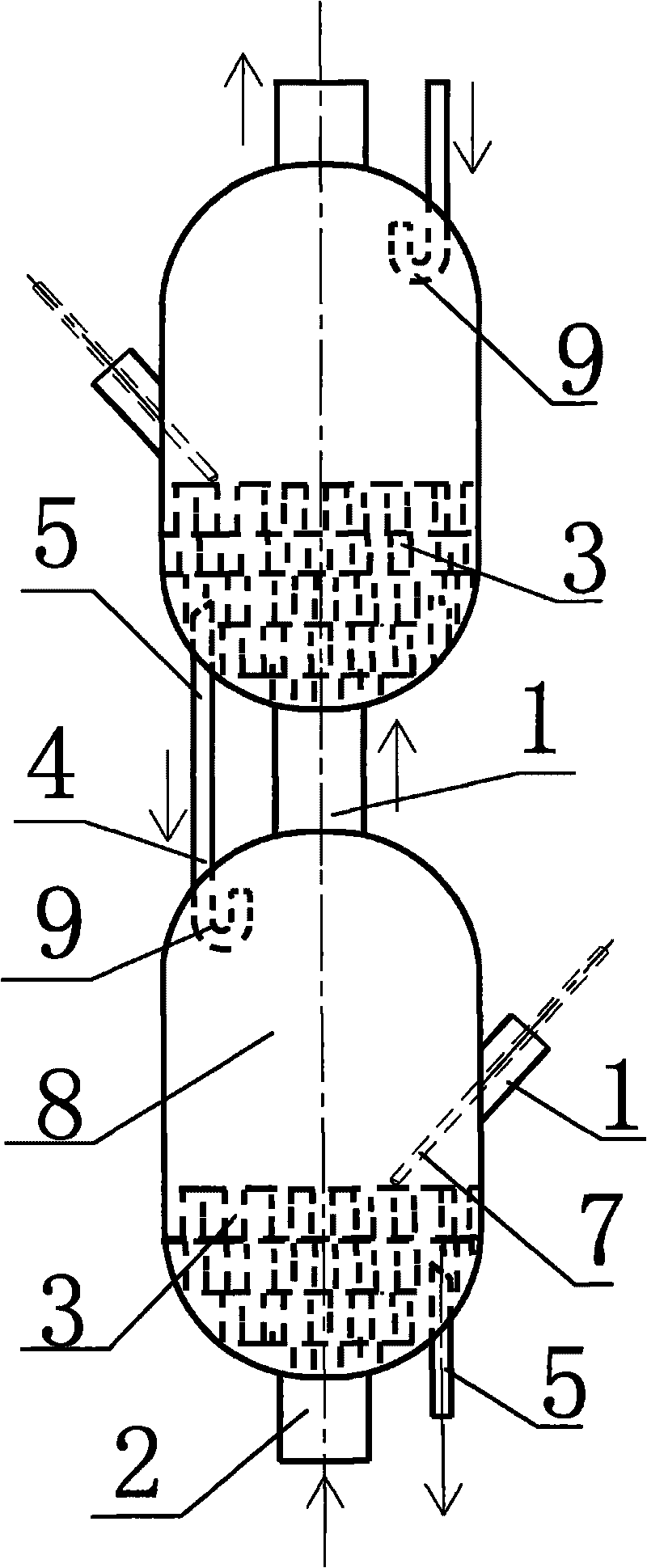

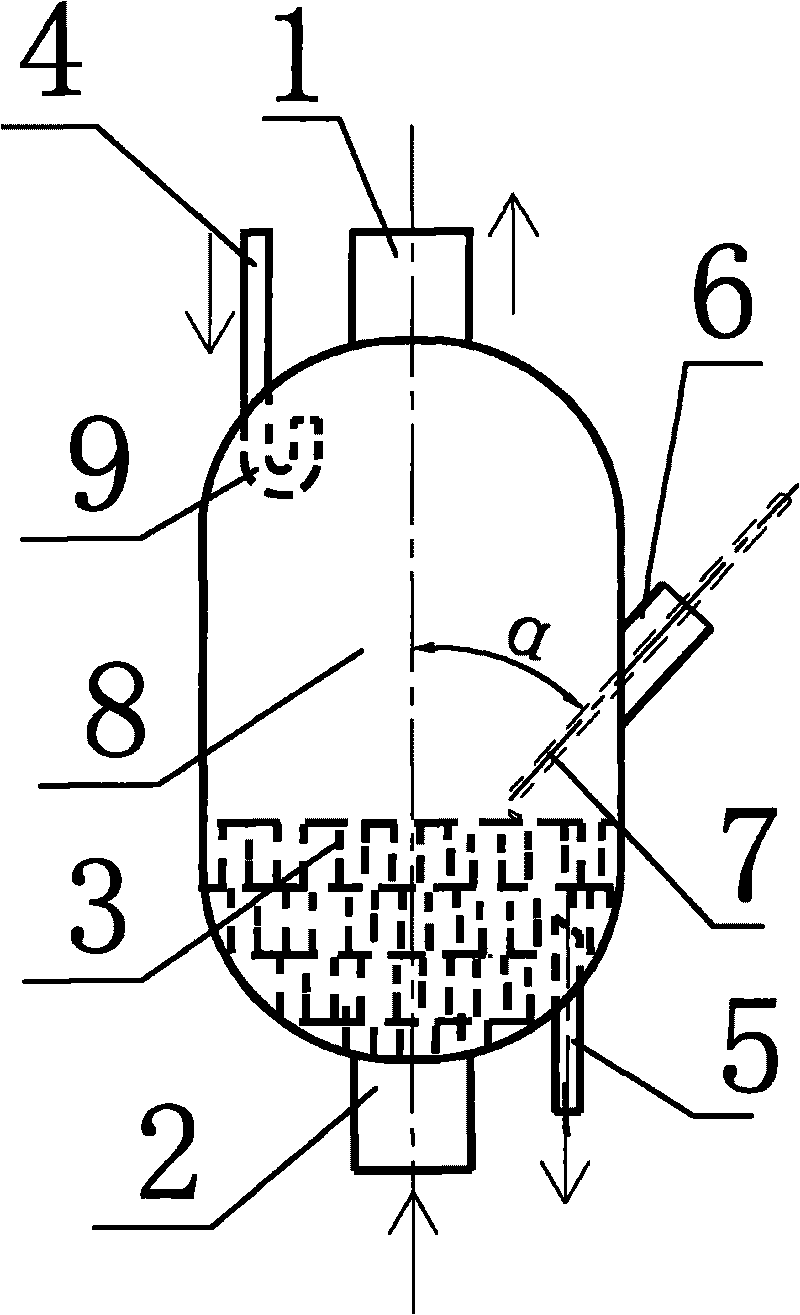

[0021] A packing tower section for chemical synthesis and rectification, refer to figure 1 As shown, a tower body 8 with a steam escape port 1 at the top and a steam rising port 2 at the bottom end, a rising steam distributor 3 arranged in the tower body 8 to distribute and guide the rising steam, the rising steam distribution The vessel 3 is preferably a combination of stainless steel wire mesh and filler. The upper part of one side of the tower body 8 is also provided with an overflow inlet pipe 4, and the lower part of the overflow inlet pipe 4 is a U-shaped liquid head 9 located in the tower body 8, the height of which is 5mm-100mm; The lower part of the side is provided with an overflow pipe 5, the upper part of the overflow pipe 5 is located in the tower body 8, and its height is 5mm-100mm, which can ensure that the overflow inlet pipe and the liquid outlet pipe have enough liquid column height to prevent steam from passing through the The overflow inlet pipe and the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com